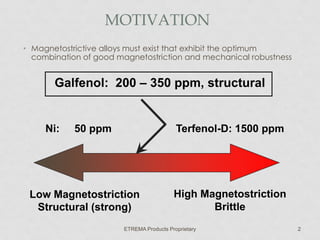

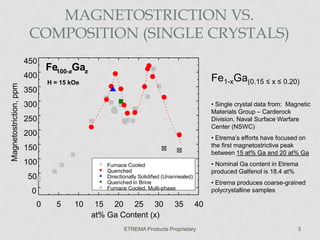

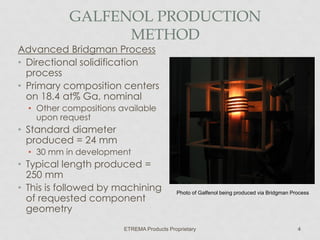

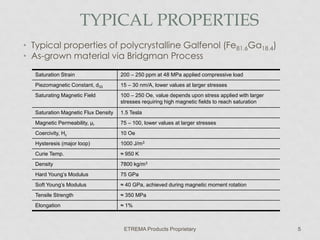

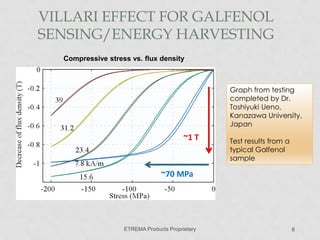

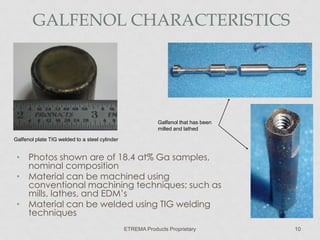

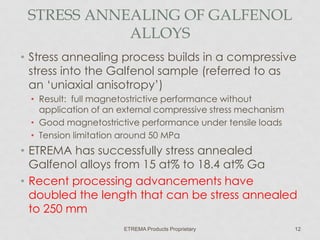

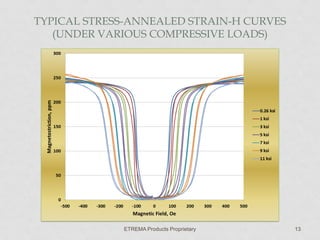

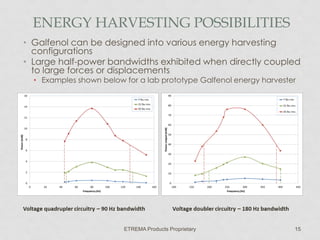

Galfenol is a new class of magnetostrictive material developed by Etrema Products, featuring a unique composition of iron and gallium that provides a balance of good magnetostriction and mechanical robustness. The material is produced using an advanced Bridgman directional solidification method and can be shaped using conventional machining techniques, offering significant potential for energy harvesting applications. Additionally, galfenol can achieve full magnetostrictive performance without external compressive loads through a stress annealing process, enhancing its practical utility in various technologies.