- Labor productivity is typically lower for larger, more complex construction projects due to logistical challenges and workers needing time to adjust to new environments.

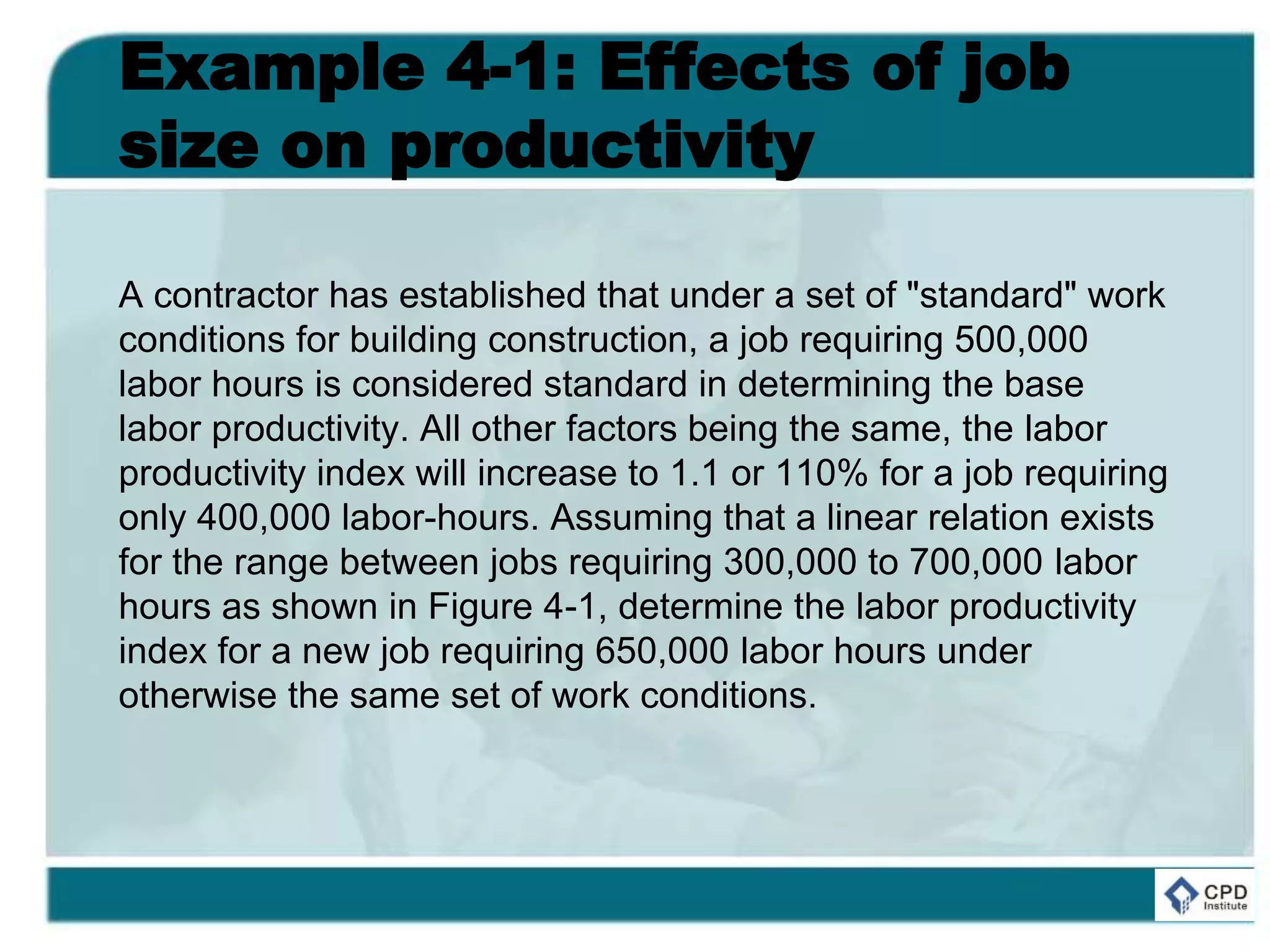

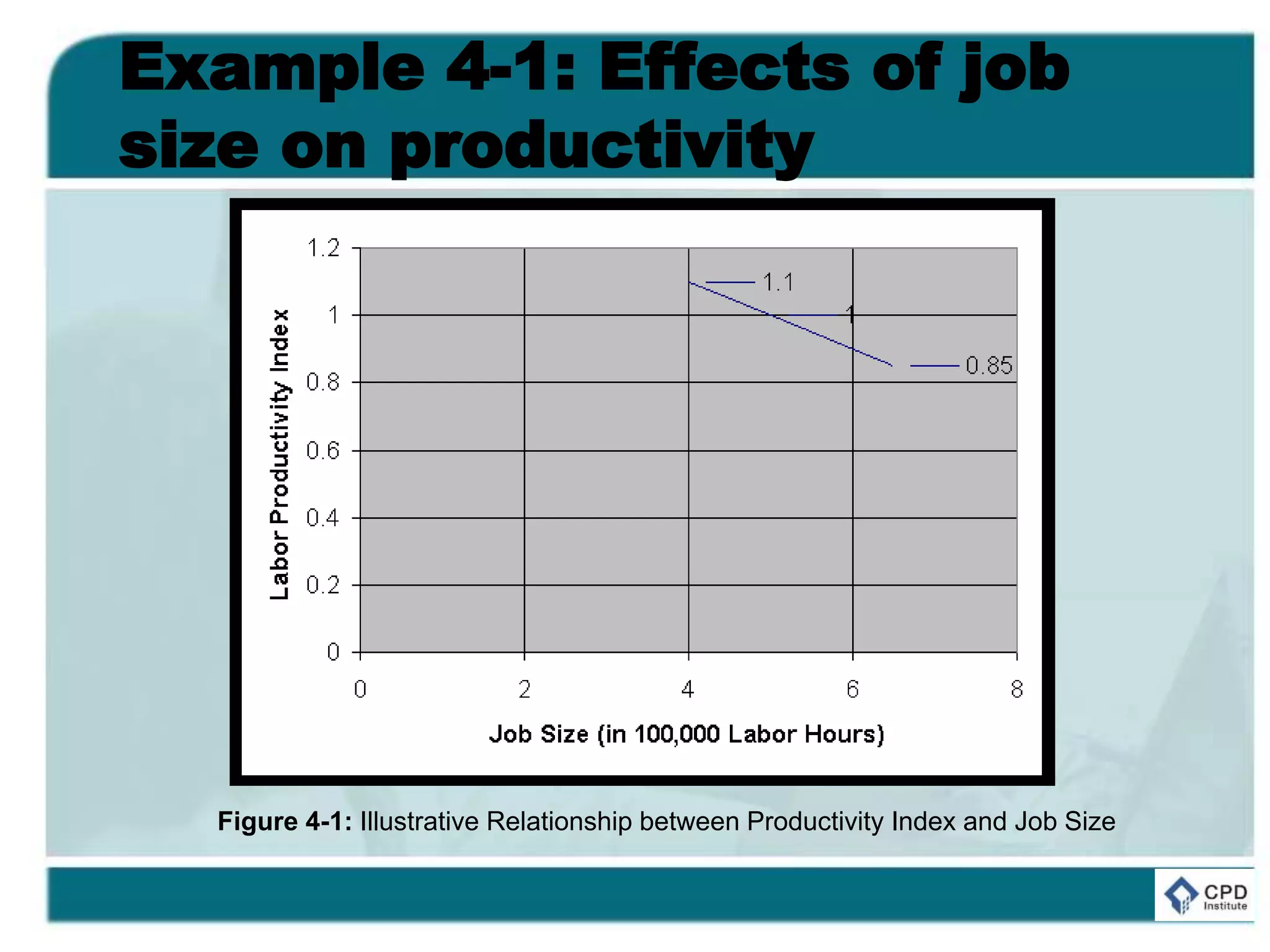

- A contractor has established a base labor productivity for jobs requiring 500,000 labor hours under standard conditions.

- For smaller jobs of 400,000 hours, productivity is 110% of the base.

- The relationship between job size and productivity is assumed to be linear from 300,000 to 700,000 hours.

- A new job requiring 650,000 hours would have a labor productivity index of 105% based on its position in the linear relationship.

![4.1 Historical Perspective

The work could not have done any faster or more efficiently in

our day, despite all technological and mechanical advances in

the time since, the reason being that no present system could

possibly carry the spoil away any faster or more efficiently than

the system employed. No motor trucks were used in the digging

of the canal; everything ran on rails. And because of the mud

and rain, no other method would have worked half so well. [1]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-6-2048.jpg)

![4.1 Historical Perspective

Bricklaying...is said not to have changed in thousands of years;

perhaps in the literal placing of brick on brick it has not. But

masonry technology has changed a great deal. Motorized

wheelbarrows and mortar mixers, sophisticated scaffolding

systems, and forklift trucks now assist the bricklayer. New

epoxy mortars give stronger adhesion between bricks. Mortar

additives and cold-weather protection eliminate winter

shutdowns. [2]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-8-2048.jpg)

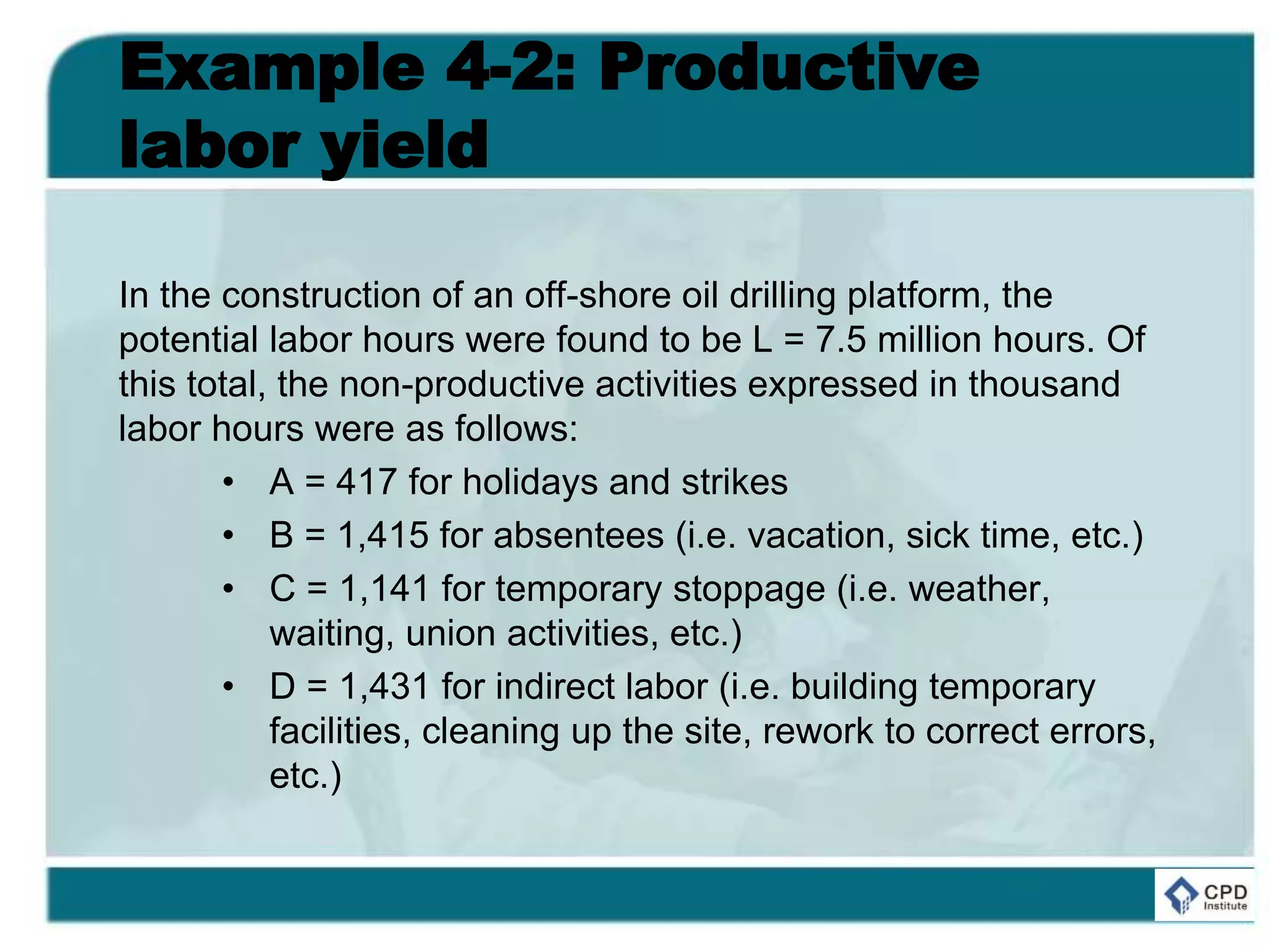

![4.3 Factors Affecting Job-

Site Productivity

Example 4-2: Productive labor yield [3]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-51-2048.jpg)

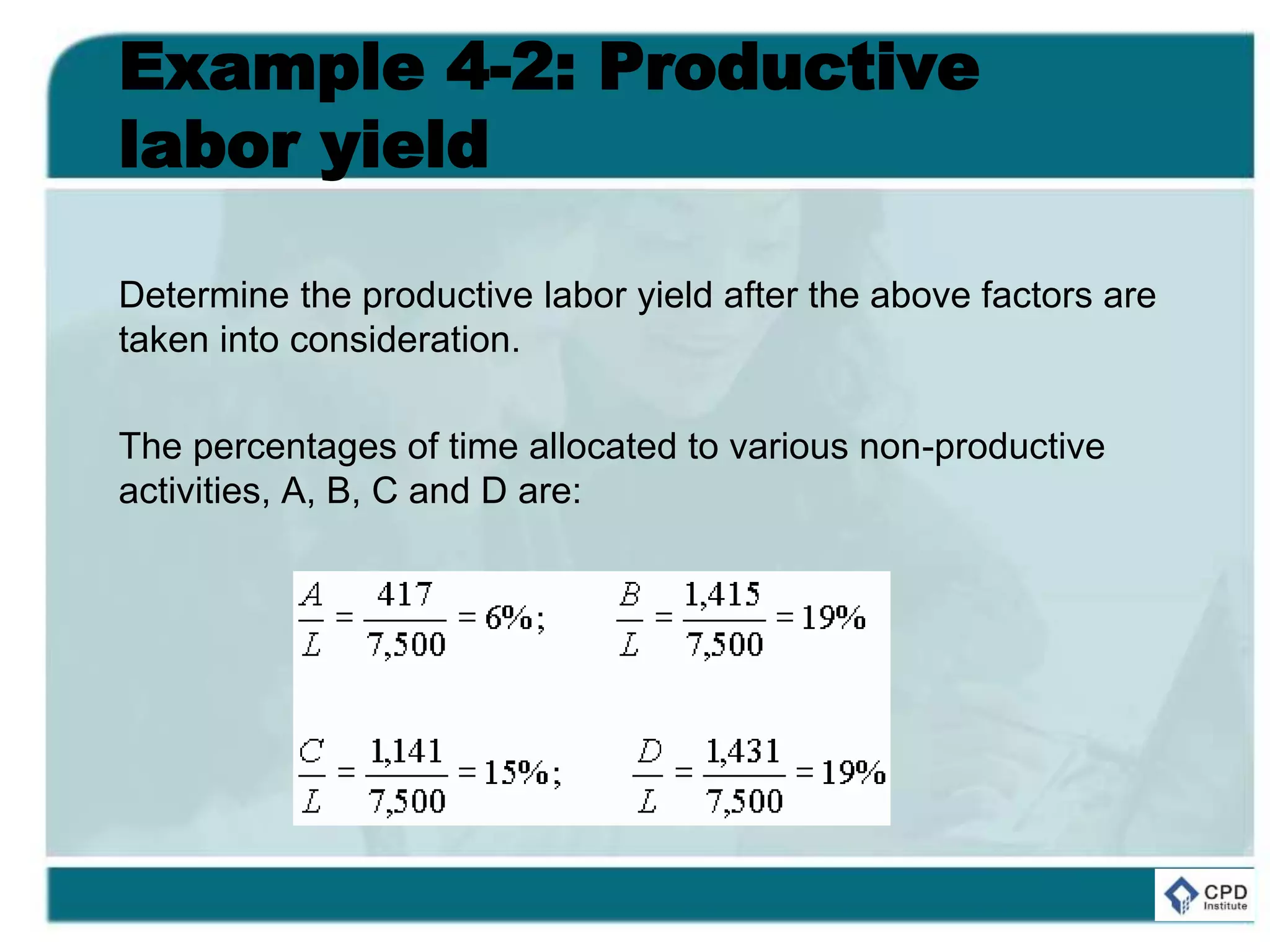

![Example 4-3: Utilization of

on-site worker's time

An example illustrating the effects of indirect labor requirements

which limit productive labor by a typical craftsman on the job

site was given by R. Tucker with the following percentages of

time allocation: [4]

Productive time

Unproductive time

Administrative delays

Inefficient work methods

Labor jurisdictions and other work

restrictions

Personal time

40%

20%

20%

15%

5%](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-56-2048.jpg)

![4.5 Problems in Collective

Bargaining

Because of the great variety of bargaining structures in which

the union and contractors' organization may choose to stage

negotiations, there are many problems arising from jurisdictional

disputes and other causes. Given the traditional rivalries among

various crafts and the ineffective organization of some of

contractors' associations, coupled with the lack of adequate

mechanisms for settling disputes, some possible solutions to

these problems deserve serious attention: [5]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-78-2048.jpg)

![4.6 Materials Management

Example 4-4: Examples of benefits for materials

management systems.[6]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-90-2048.jpg)

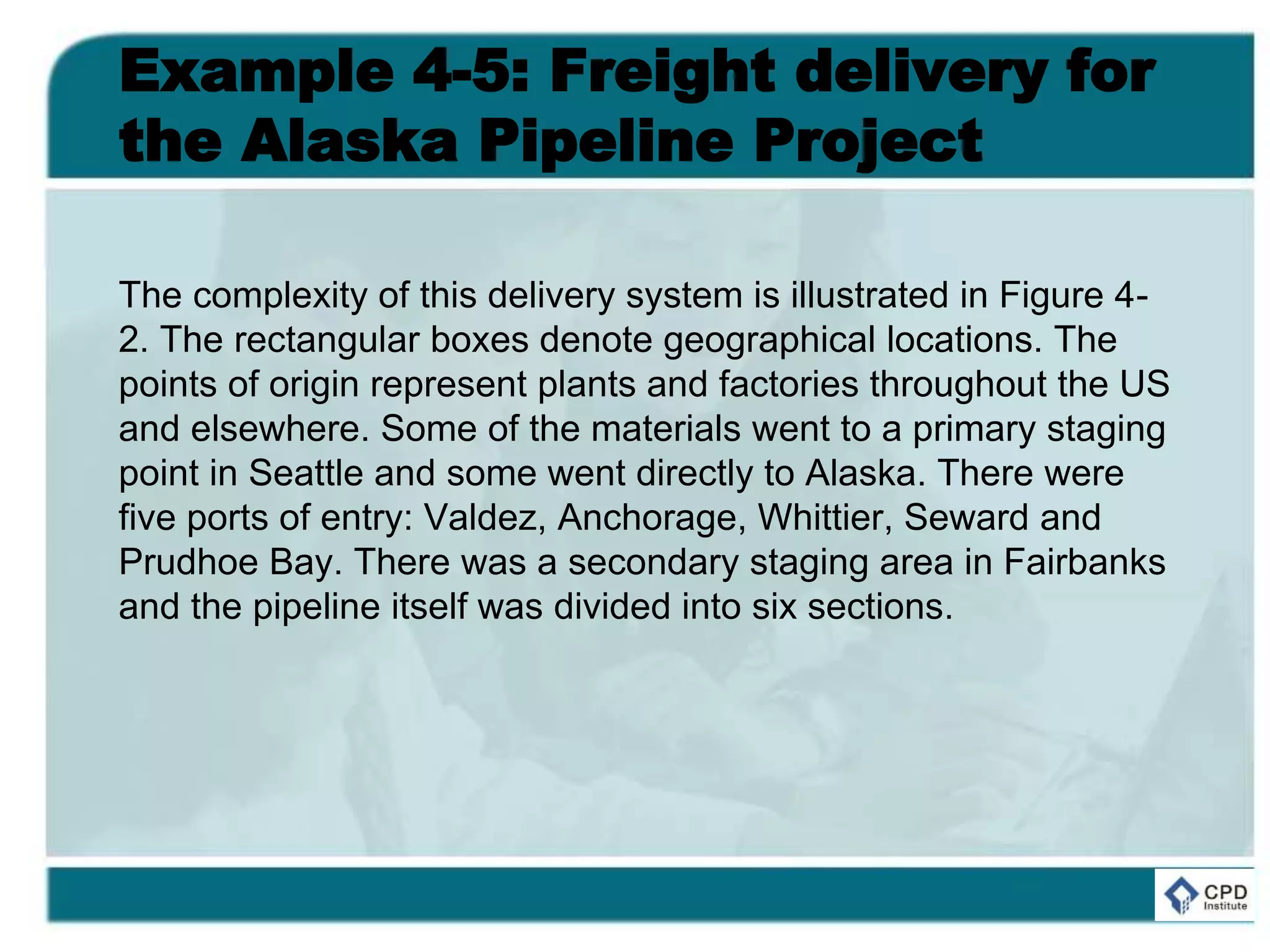

![4.7 Material Procurement and

Delivery

Example 4-5: Freight delivery for the Alaska Pipeline

Project [7]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-102-2048.jpg)

![4.10 Construction Equipment

The selection of the appropriate type and size of construction

equipment often affects the required amount of time and effort

and thus the job-site productivity of a project. It is therefore

important for site managers and construction planners to be

familiar with the characteristics of the major types of equipment

most commonly used in construction. [9]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-140-2048.jpg)

![Automation of Equipment

For example, wrenches that automatically monitor the

elongation of bolts and the applied torque can be programmed

to achieve the best bolt tightness. On grading projects, laser

controlled scrapers can produce desired cuts faster and more

precisely than wholly manual methods. [10] Possibilities for

automation and robotics in construction are explored more fully

in Chapter 16.](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-168-2048.jpg)

![4.10 Construction Equipment

Example 4-8: Tunneling Equipment [11]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-169-2048.jpg)

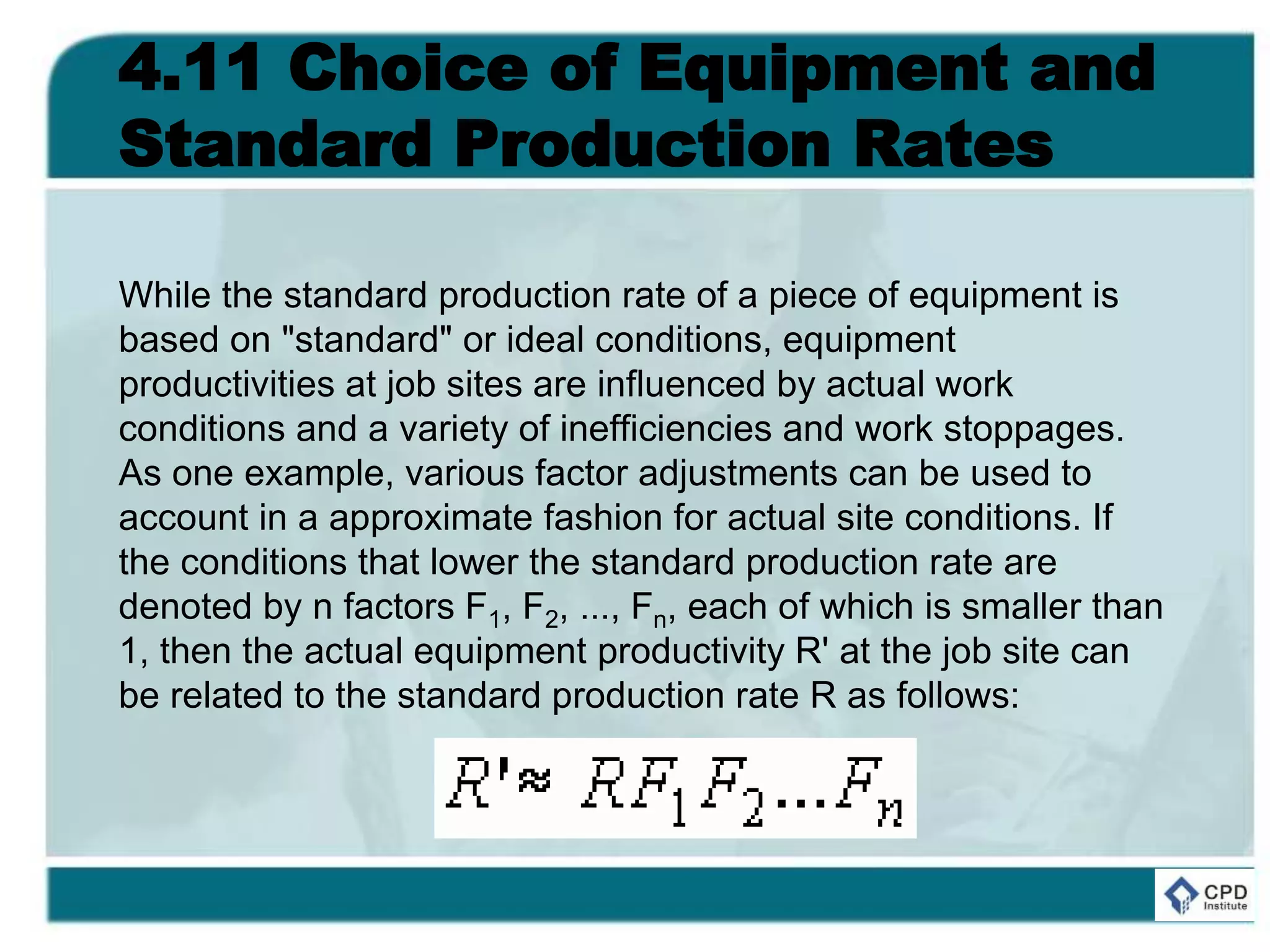

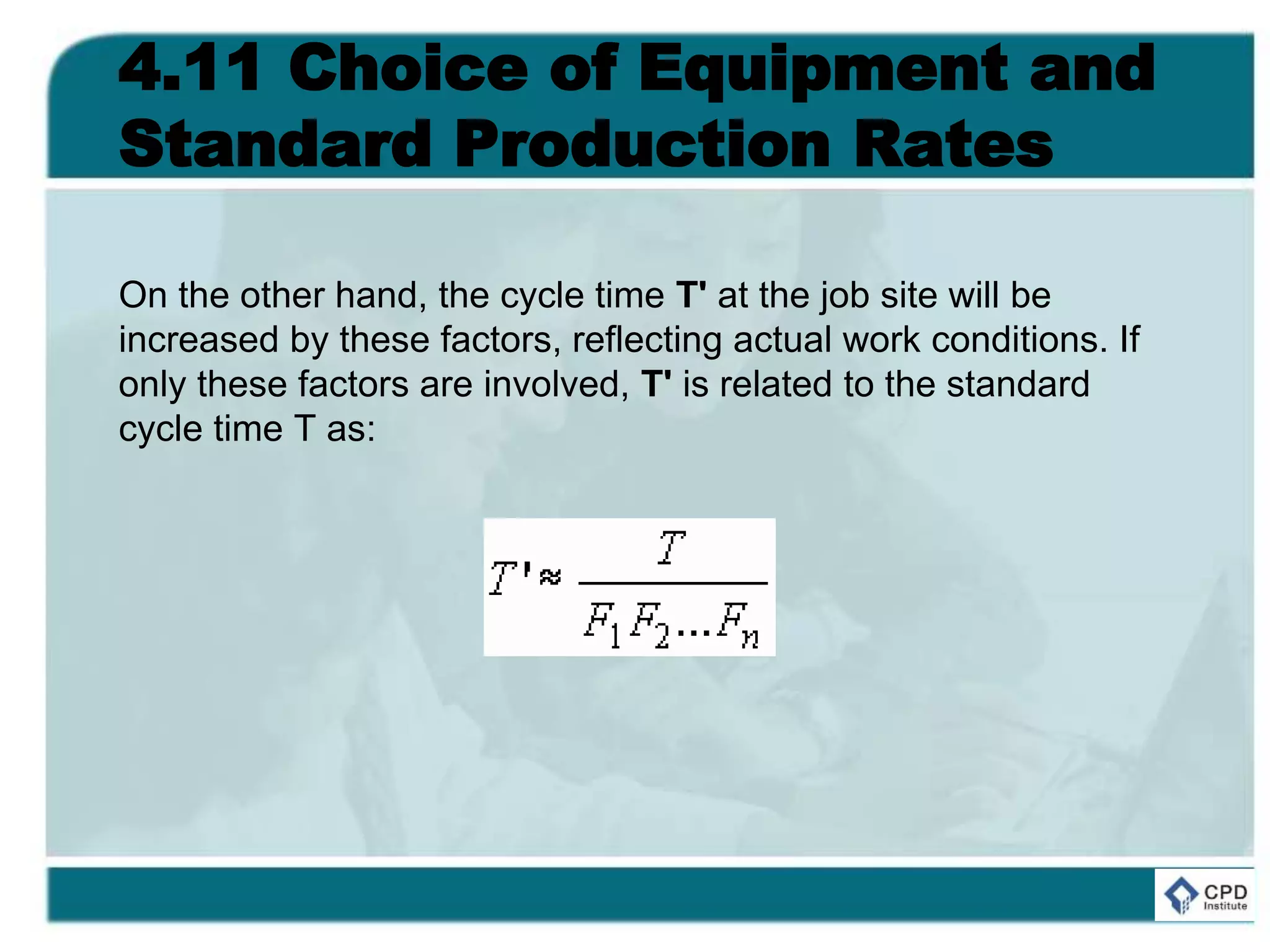

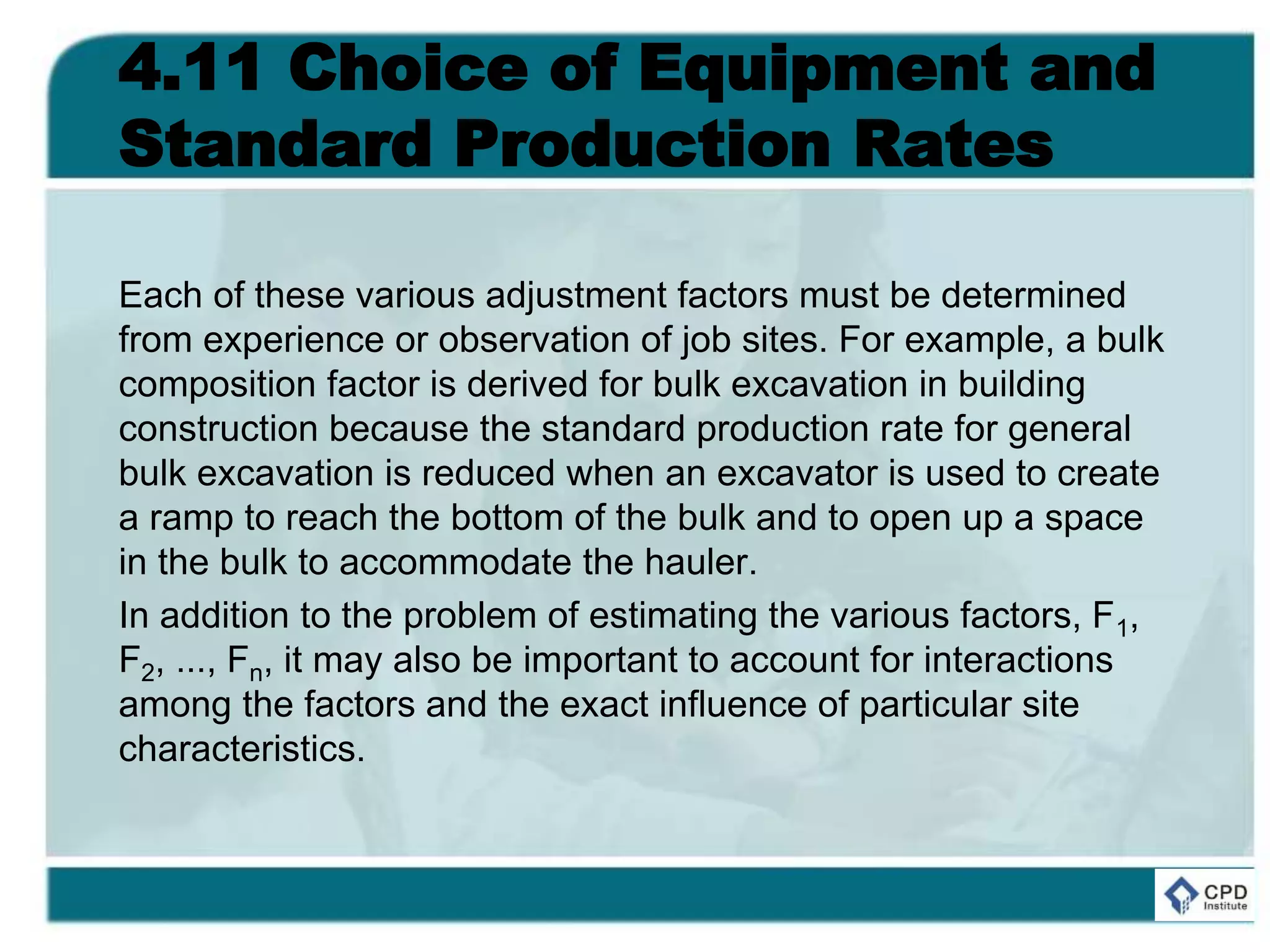

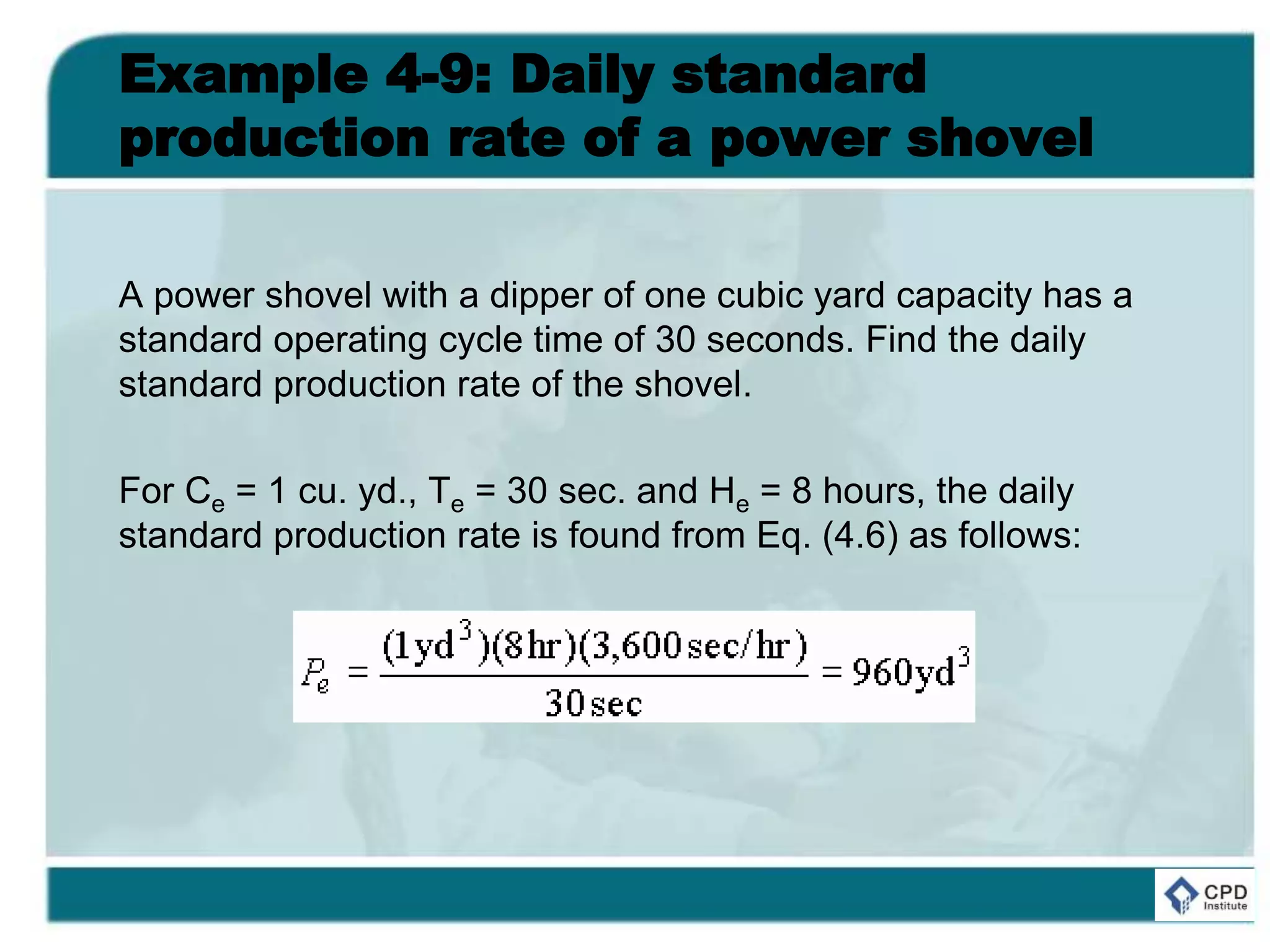

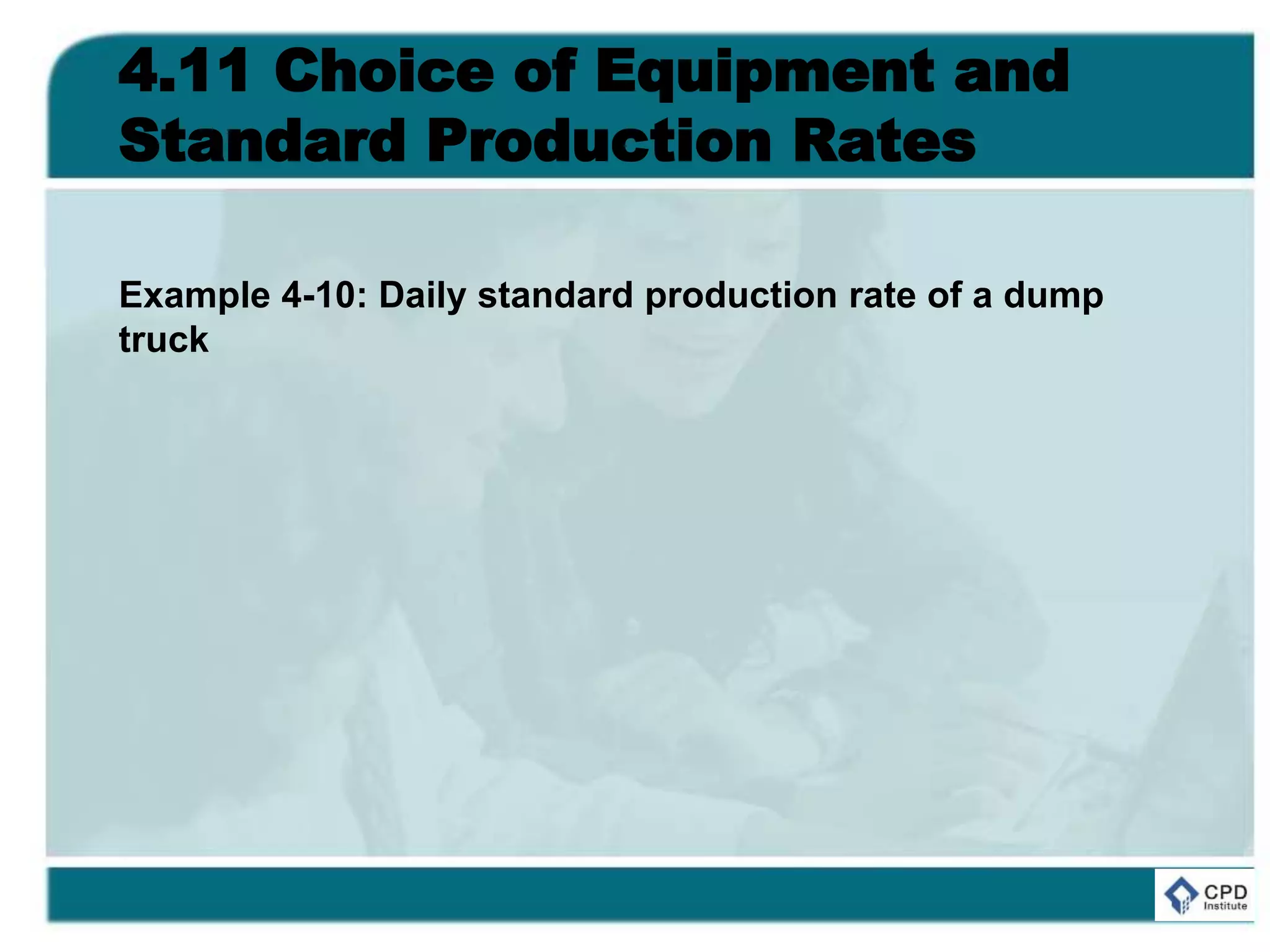

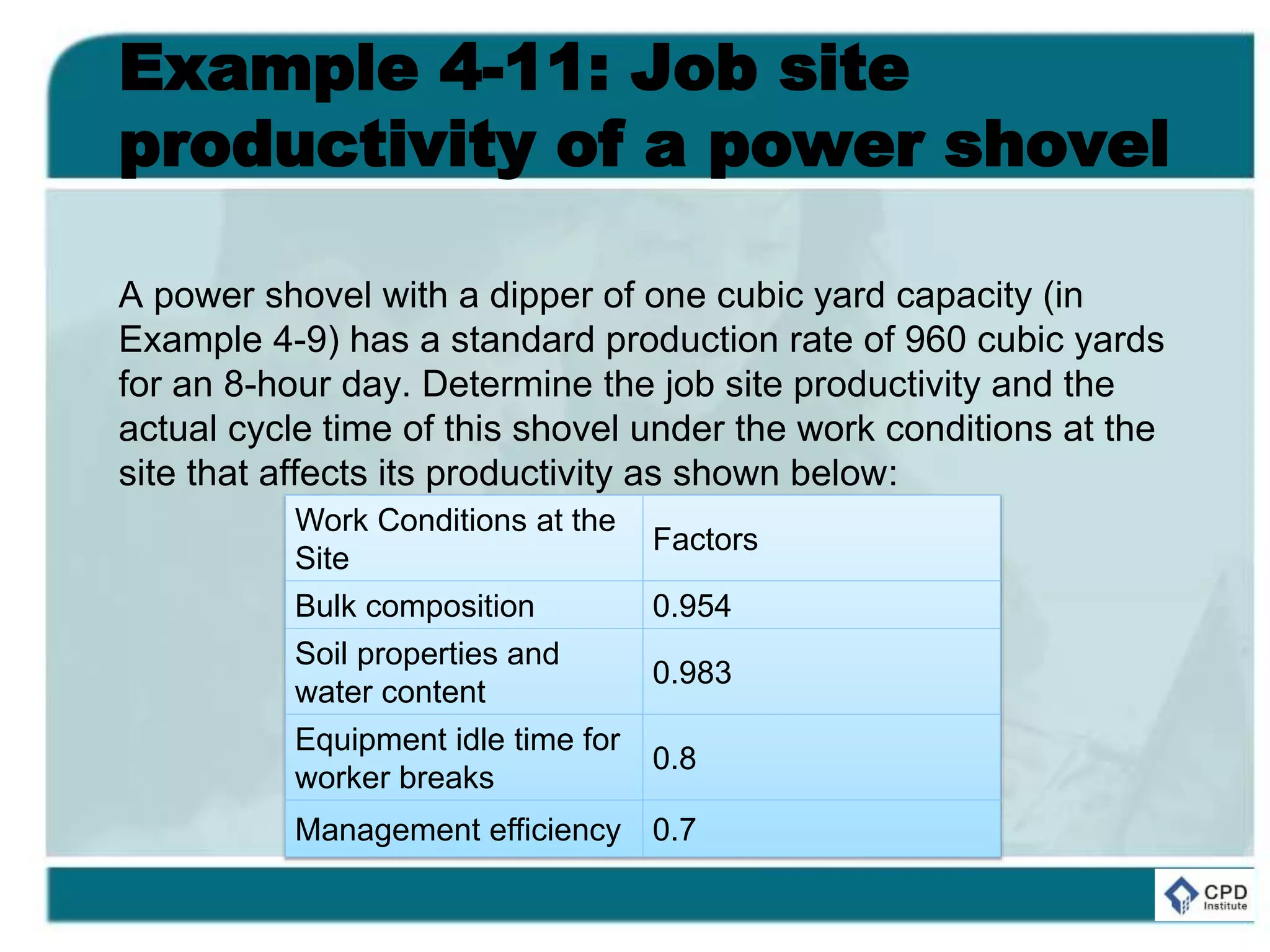

![4.11 Choice of Equipment and

Standard Production Rates

Example 4-9: Daily standard production rate of a power

shovel [12]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-192-2048.jpg)

![Example 4-14: Construction

process simulation models

Computer based simulation of construction operations can be a

useful although laborious tool in analyzing the efficiency of

particular processes or technologies. These tools tend to be

either oriented toward modeling resource processes or towards

representation of spatial constraints and resource movements.

Later chapters will describe simulation in more detail, but a

small example of a construction operation model can be

described here. [13]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-216-2048.jpg)

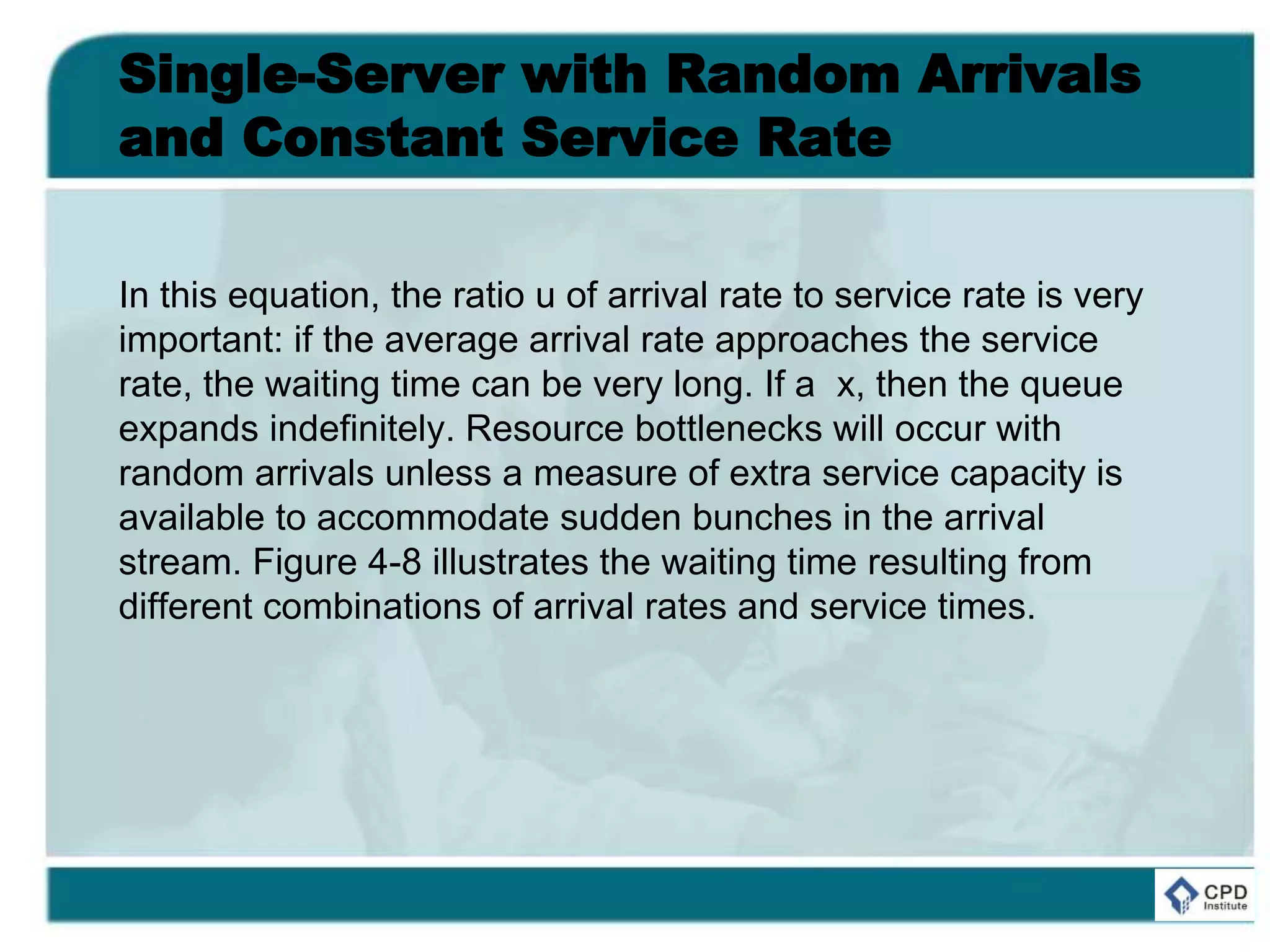

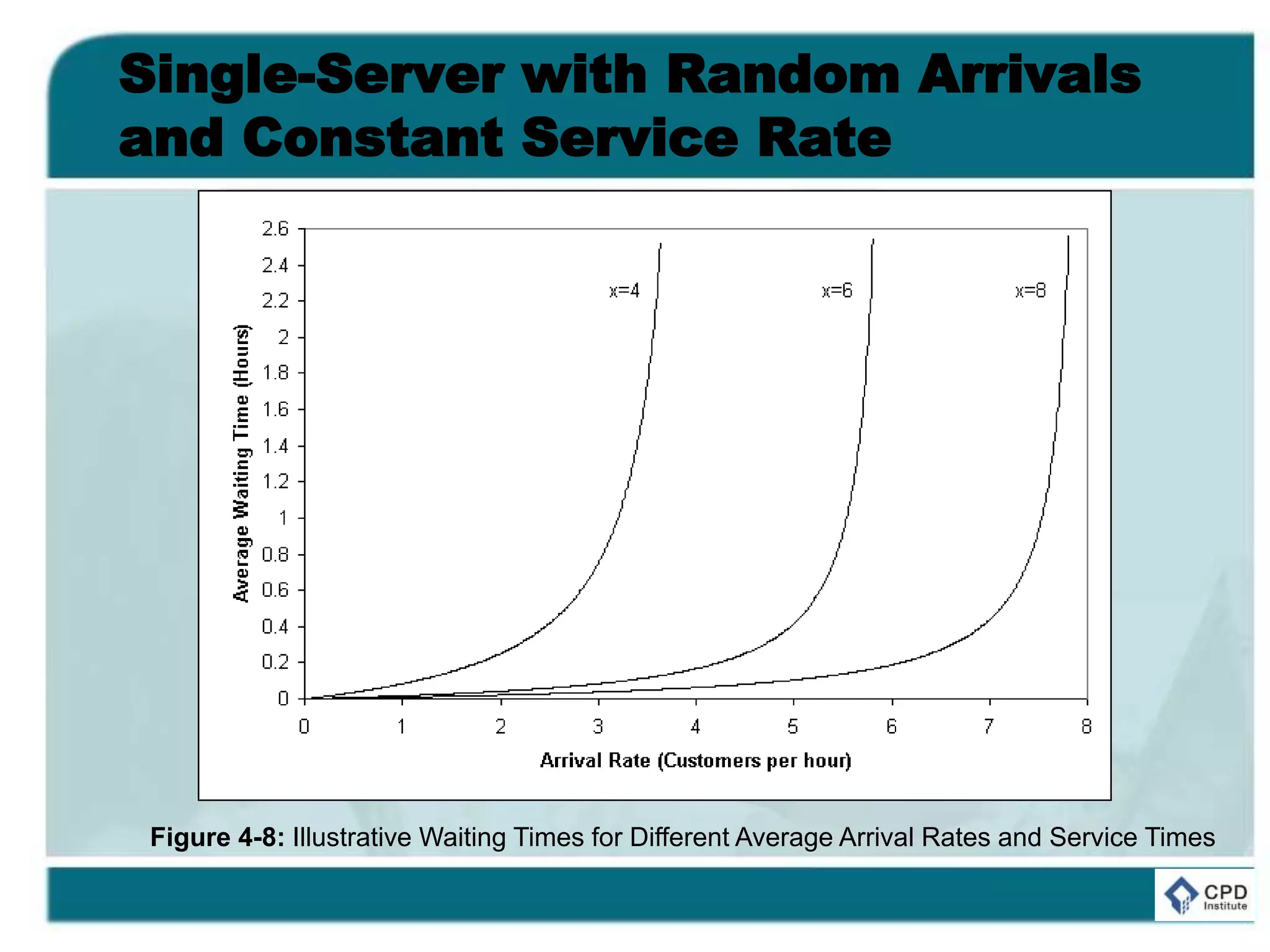

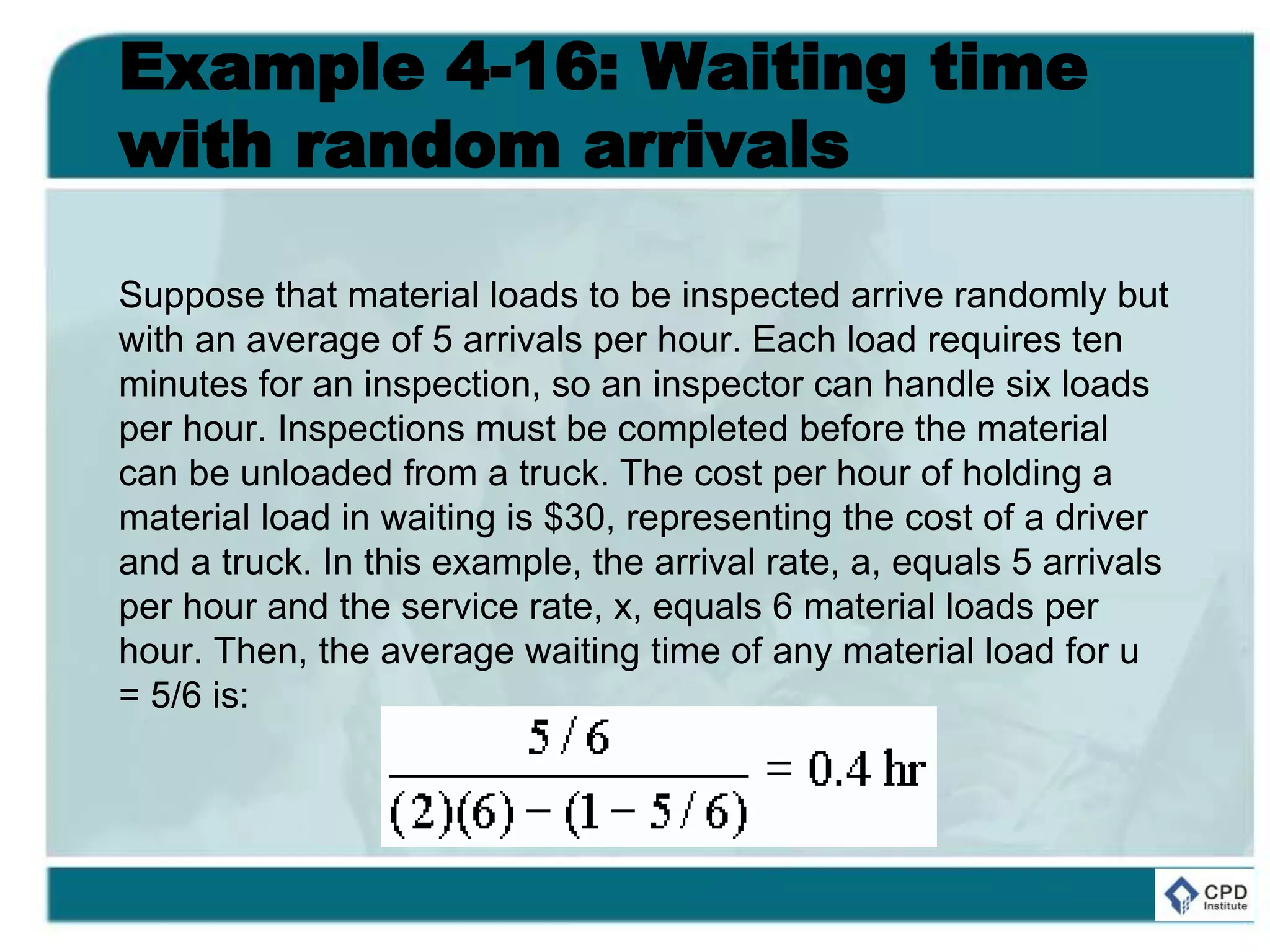

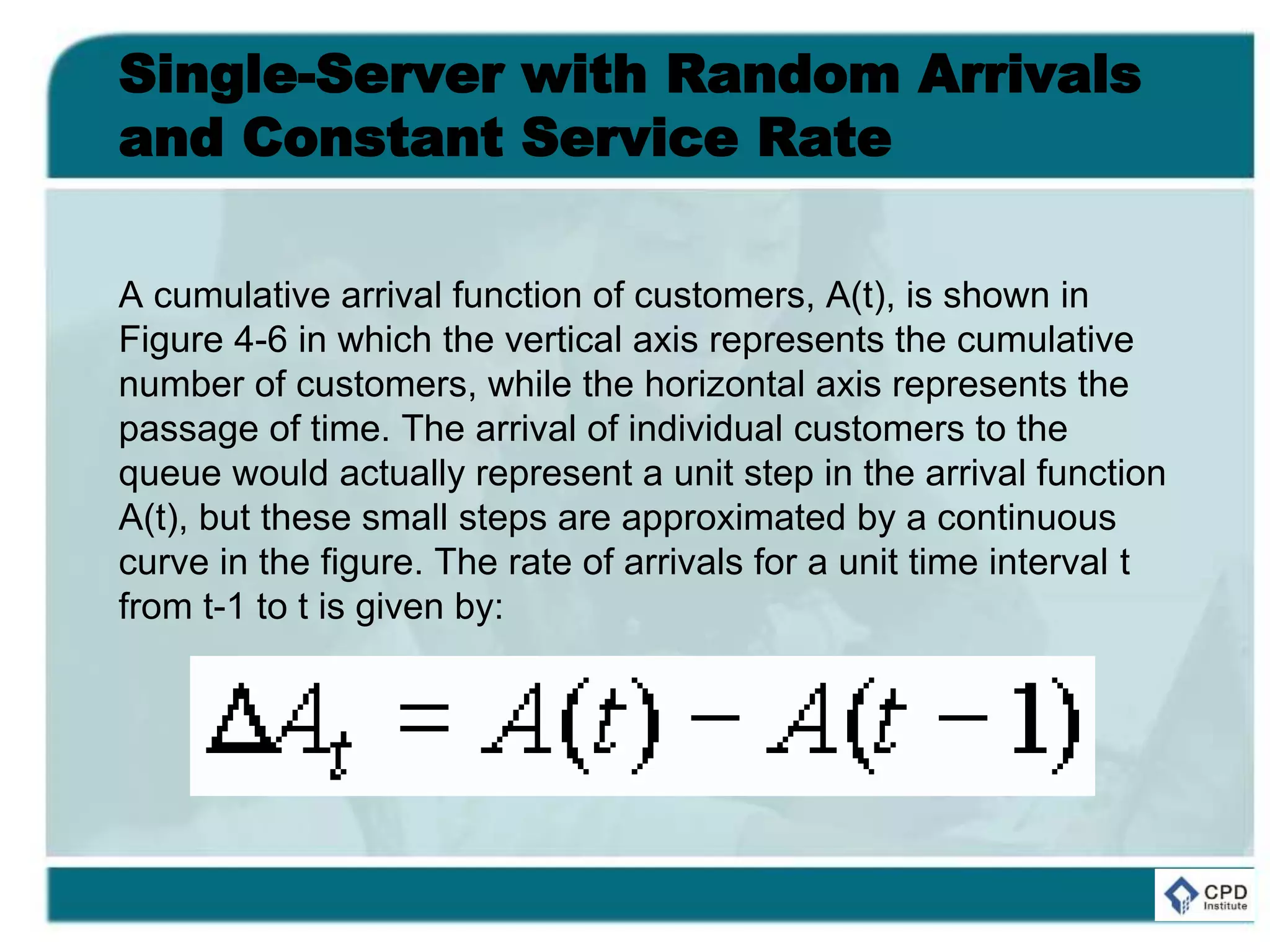

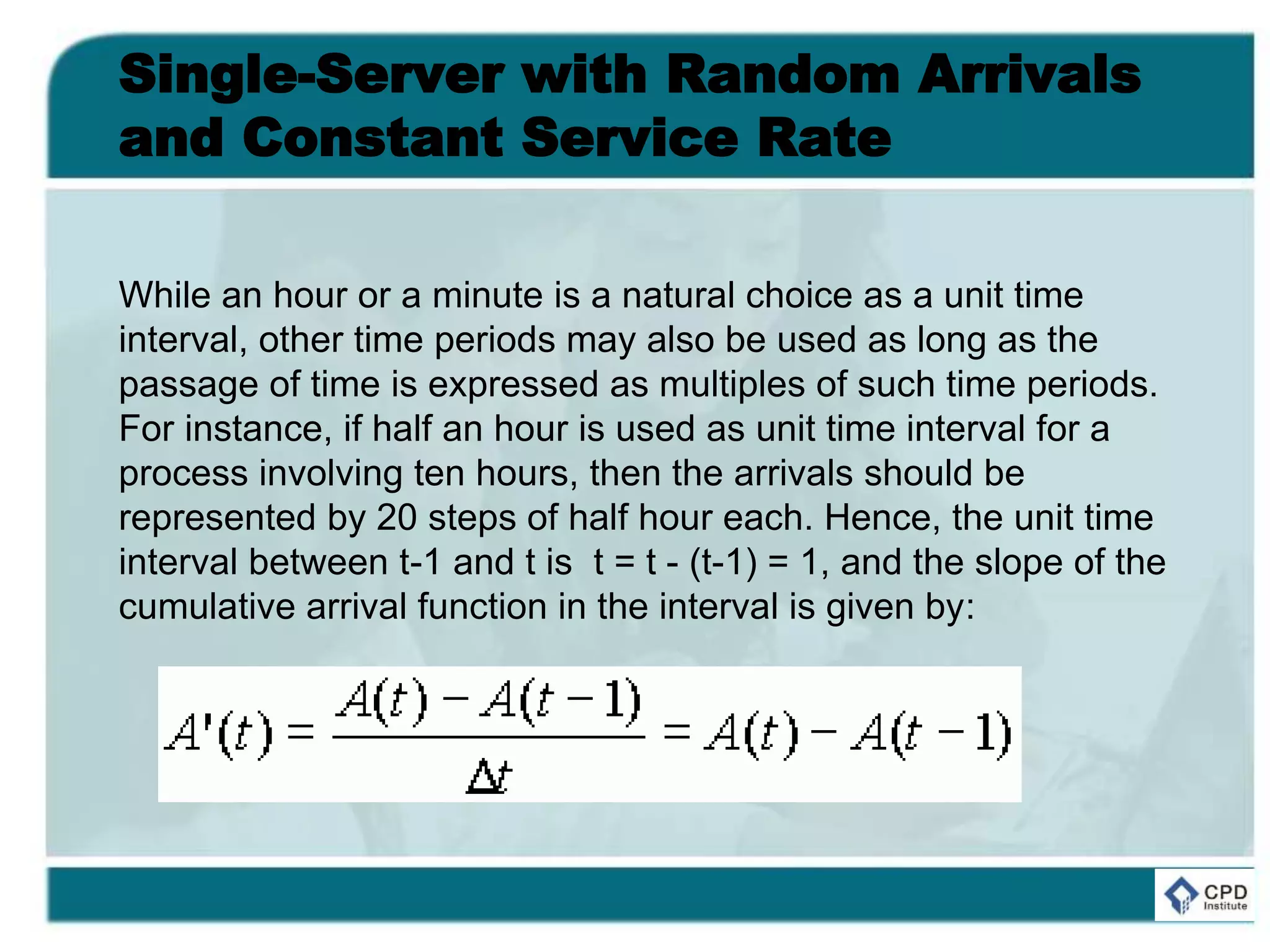

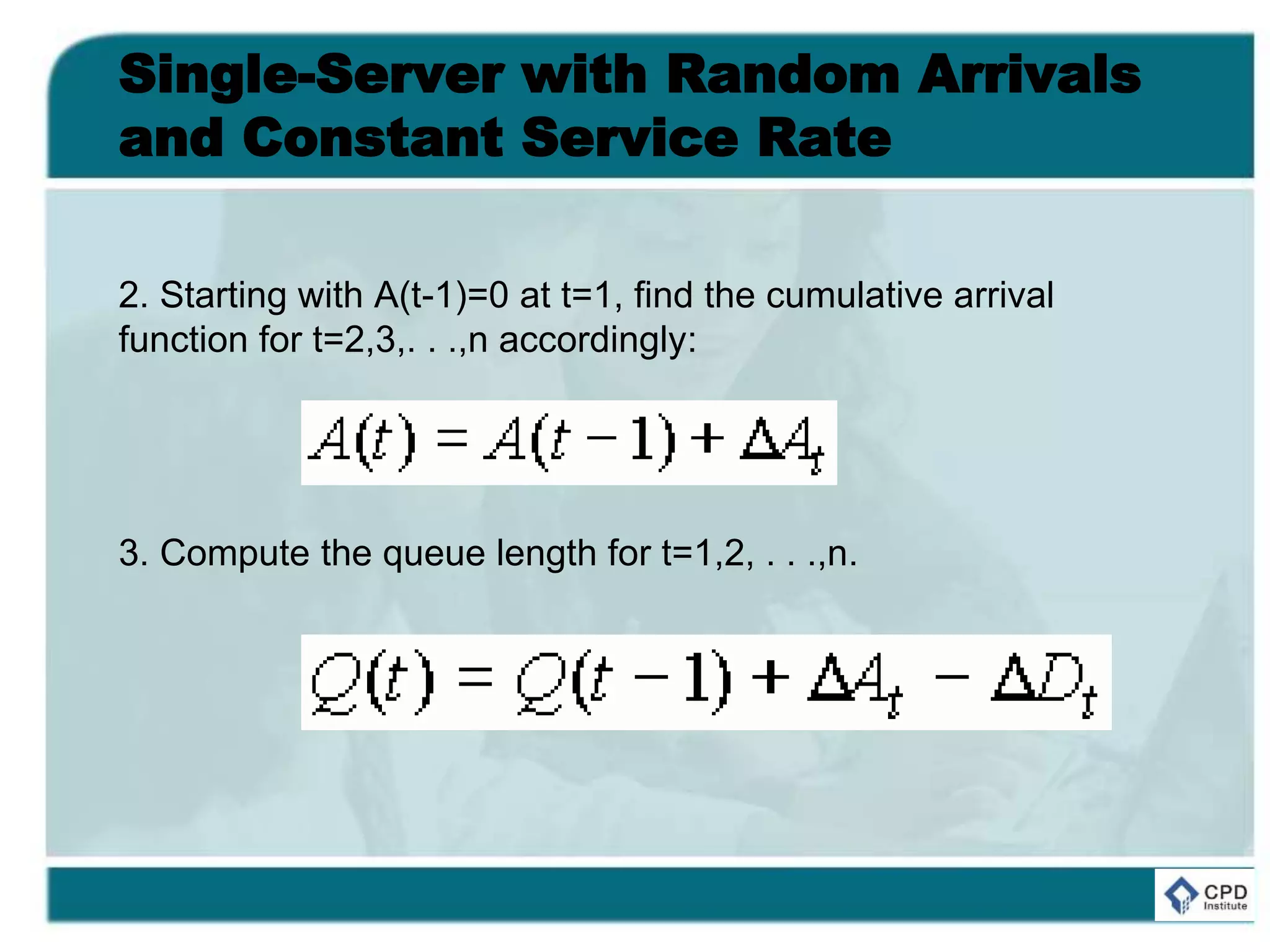

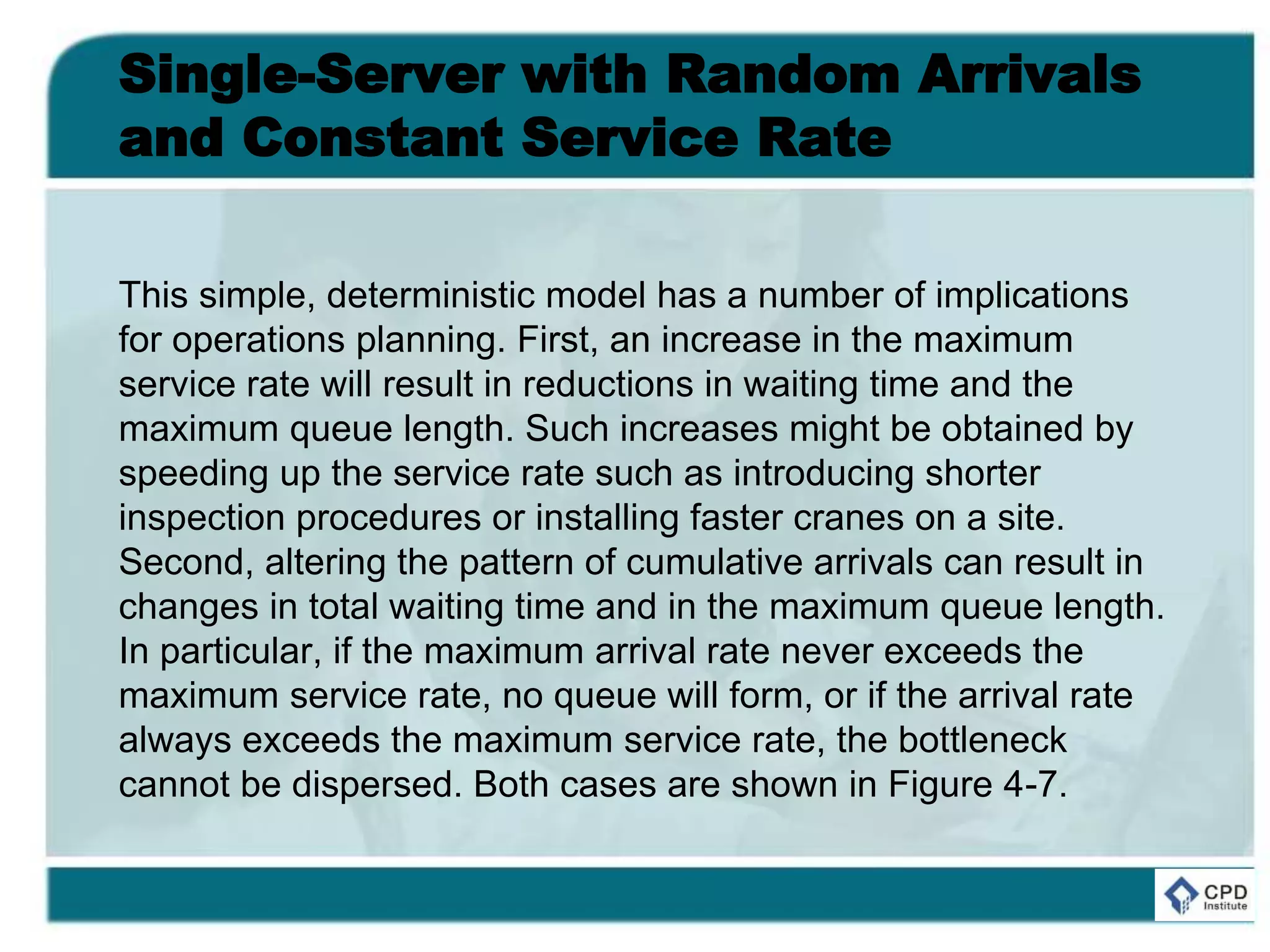

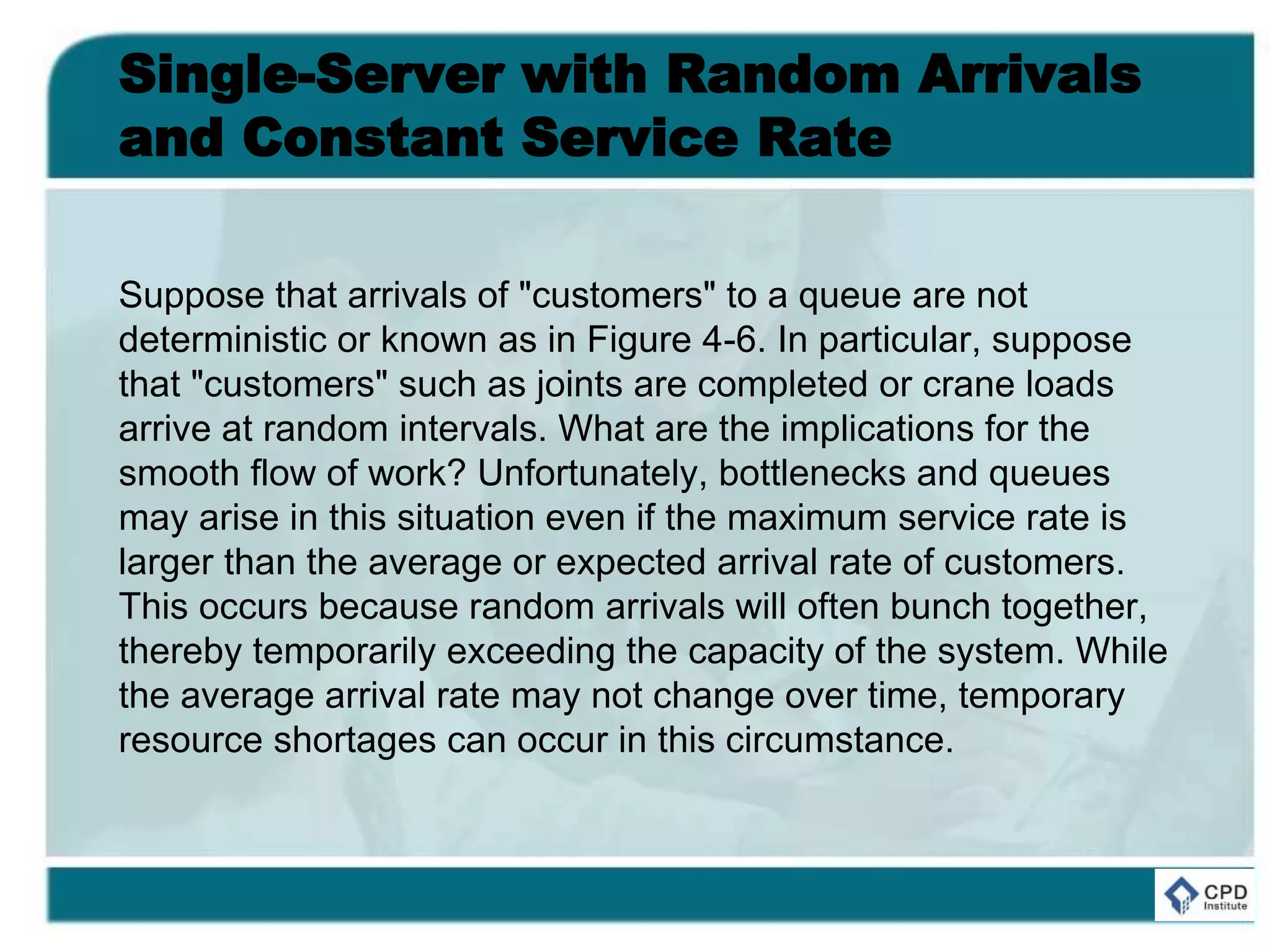

![Single-Server with Random Arrivals

and Constant Service Rate

Let w be the average waiting time, a be the average arrival rate

of customers, and x be the deterministic constant service rate

(in customers per unit of time). Then, the expected average

time for a customer in this situation is given by: [14]](https://image.slidesharecdn.com/projectmanagementchapter4-181005230055/75/Project-management-chapter-4-264-2048.jpg)