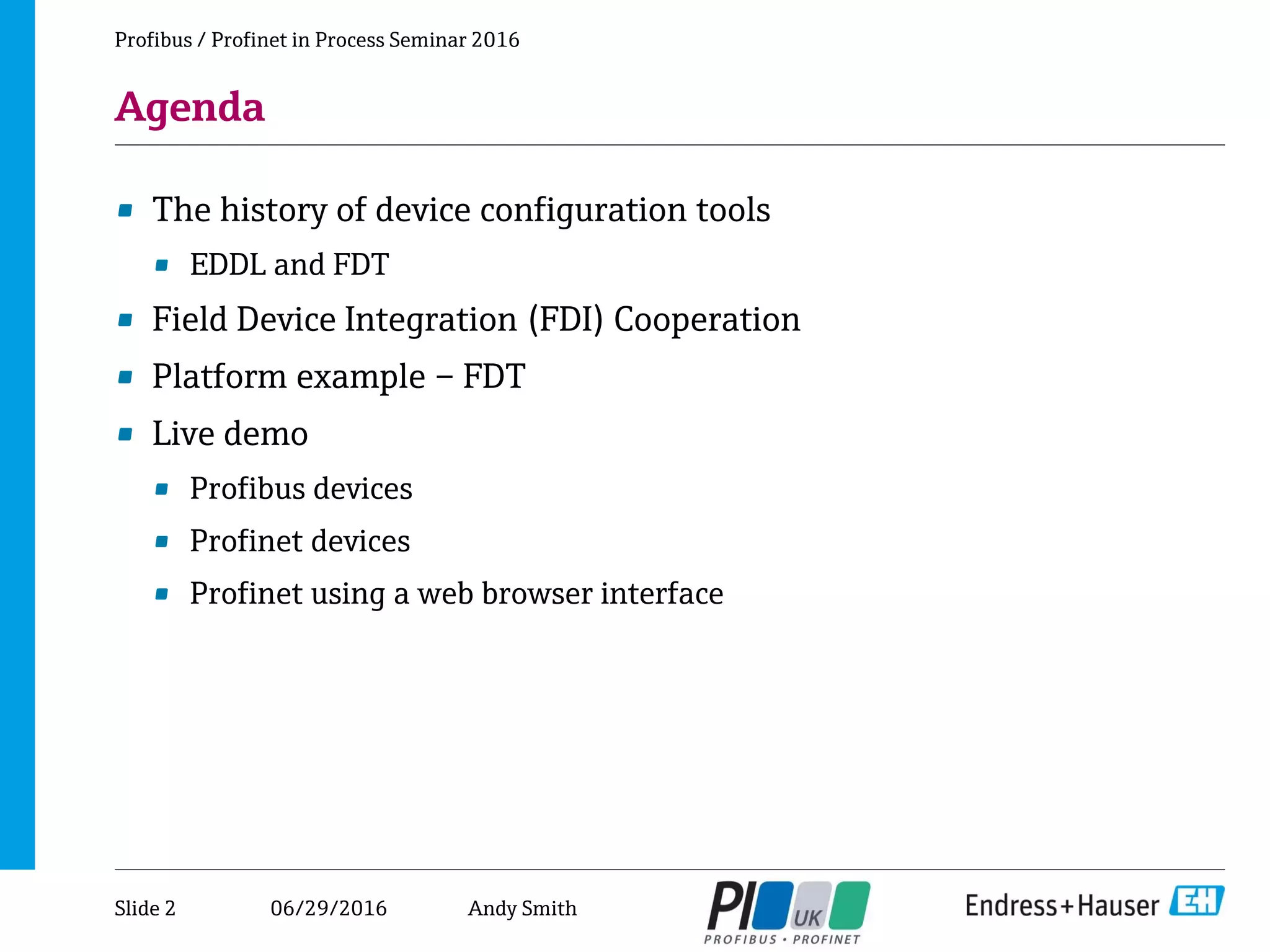

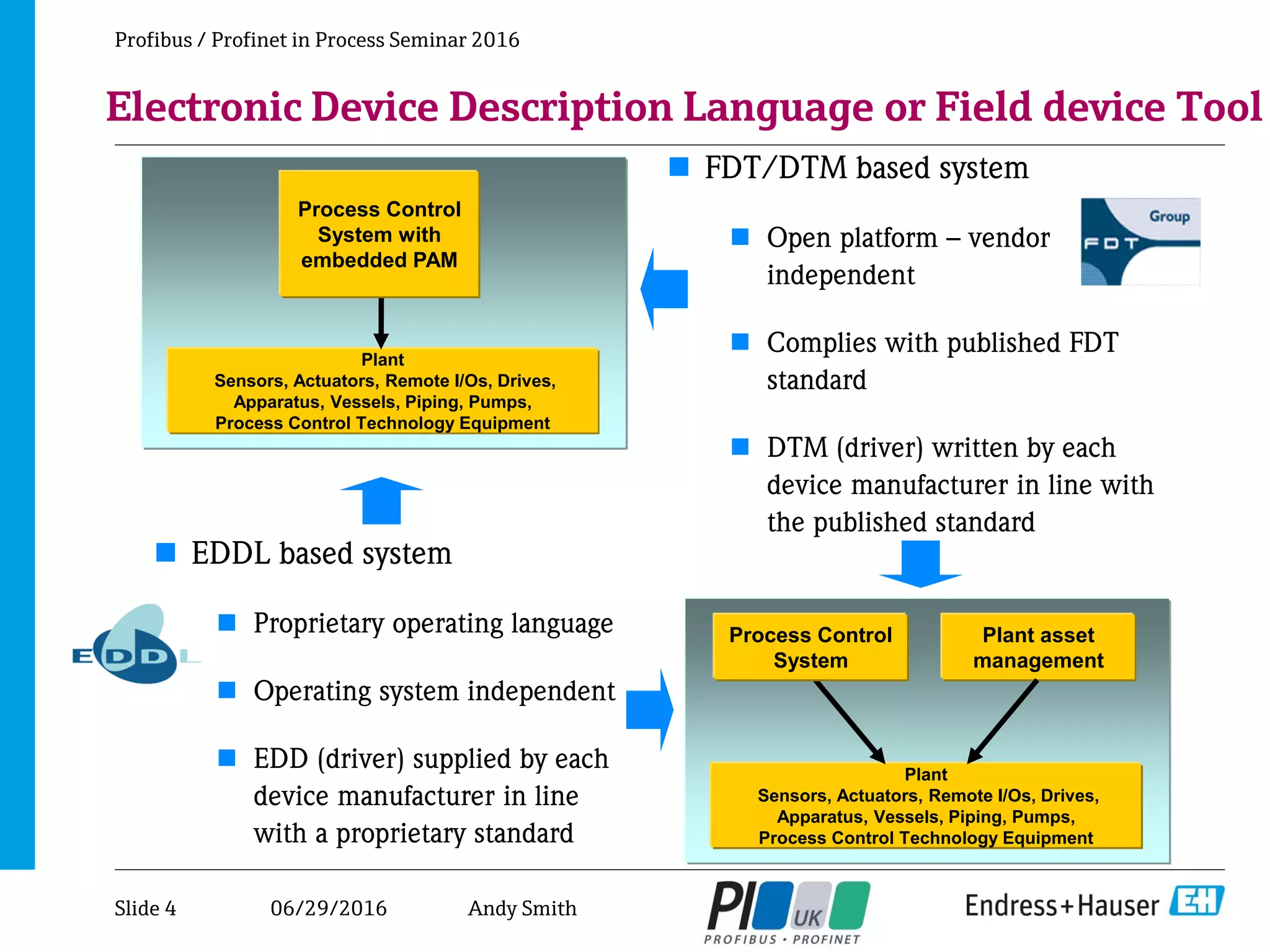

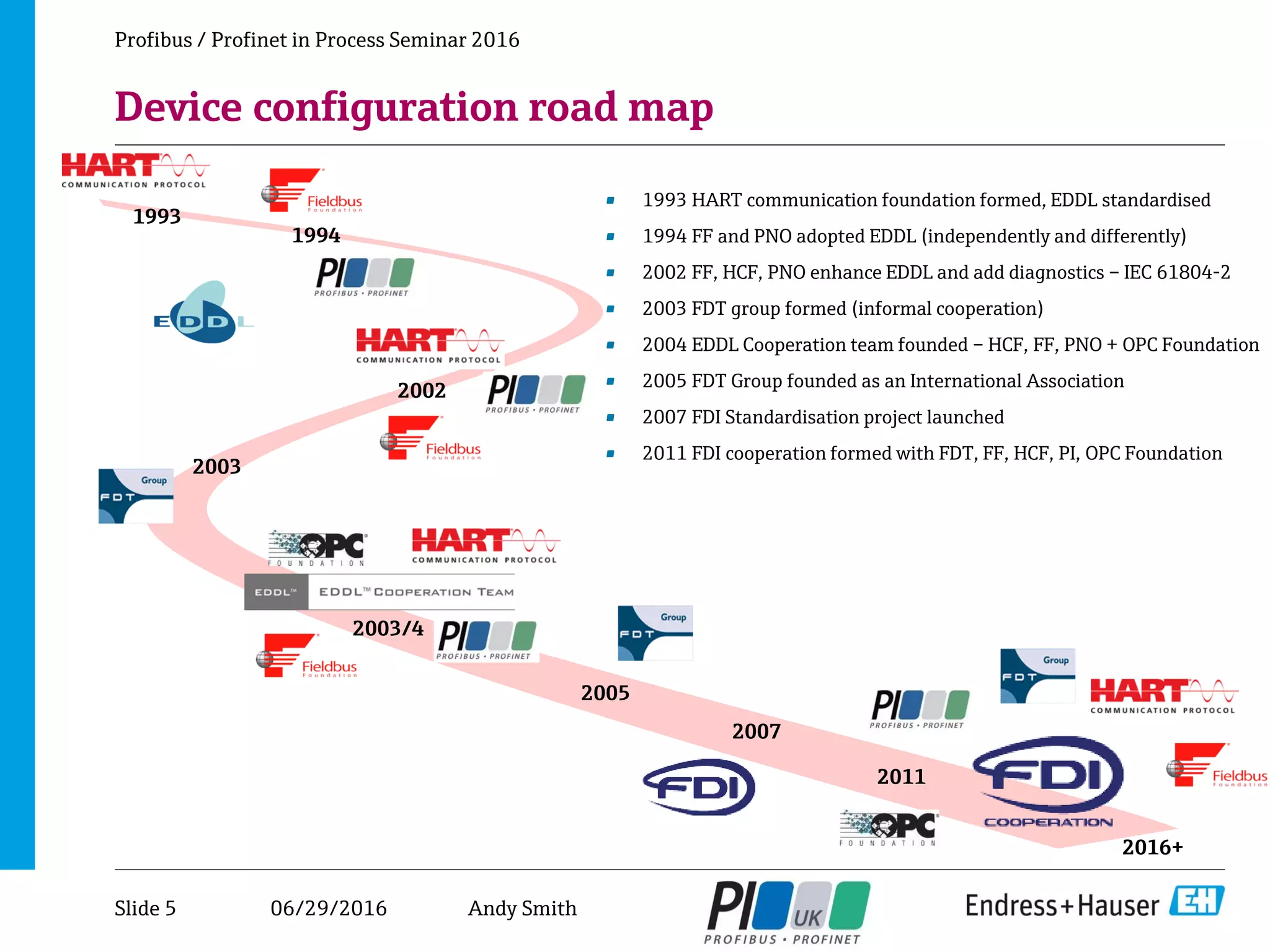

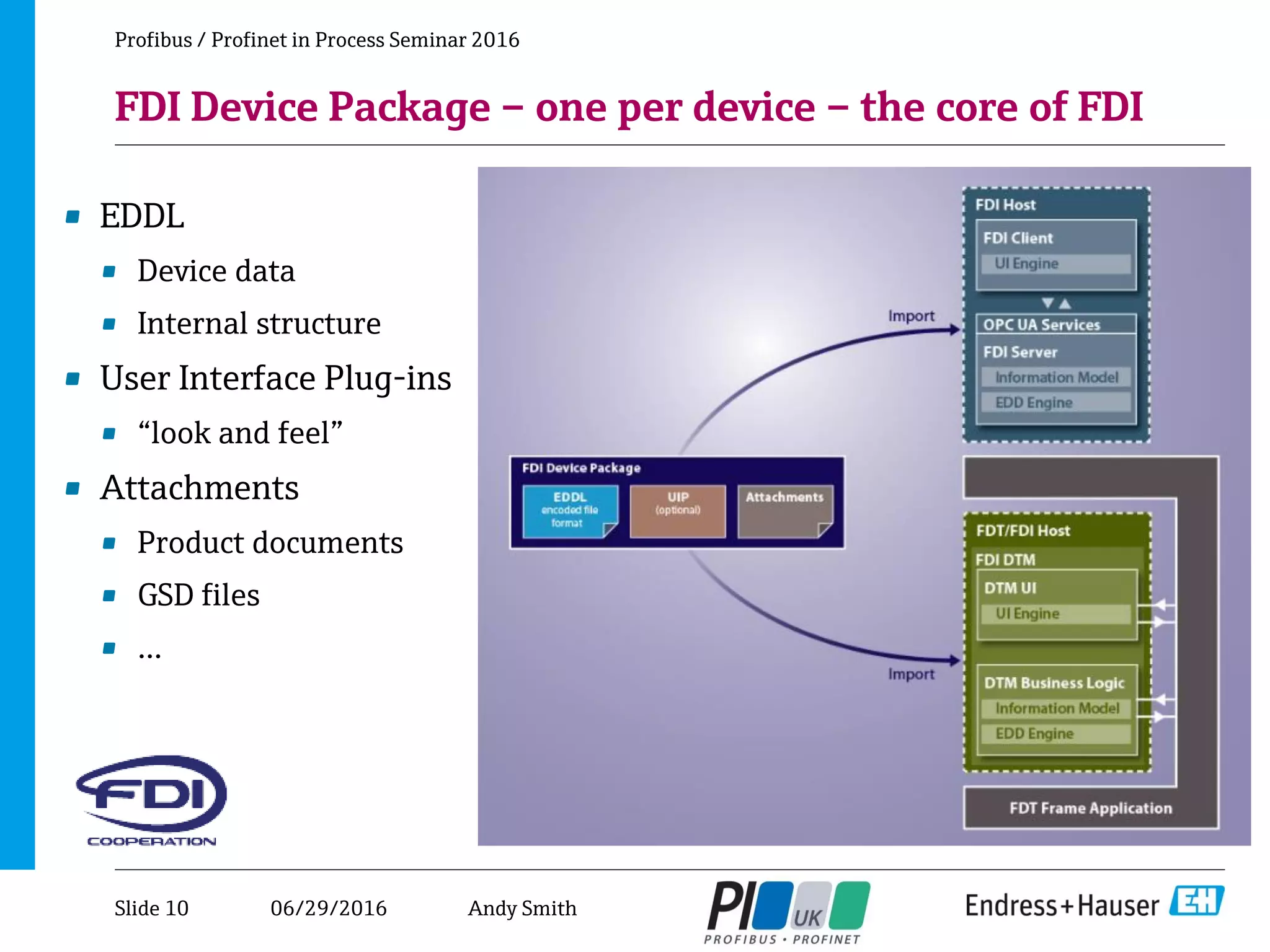

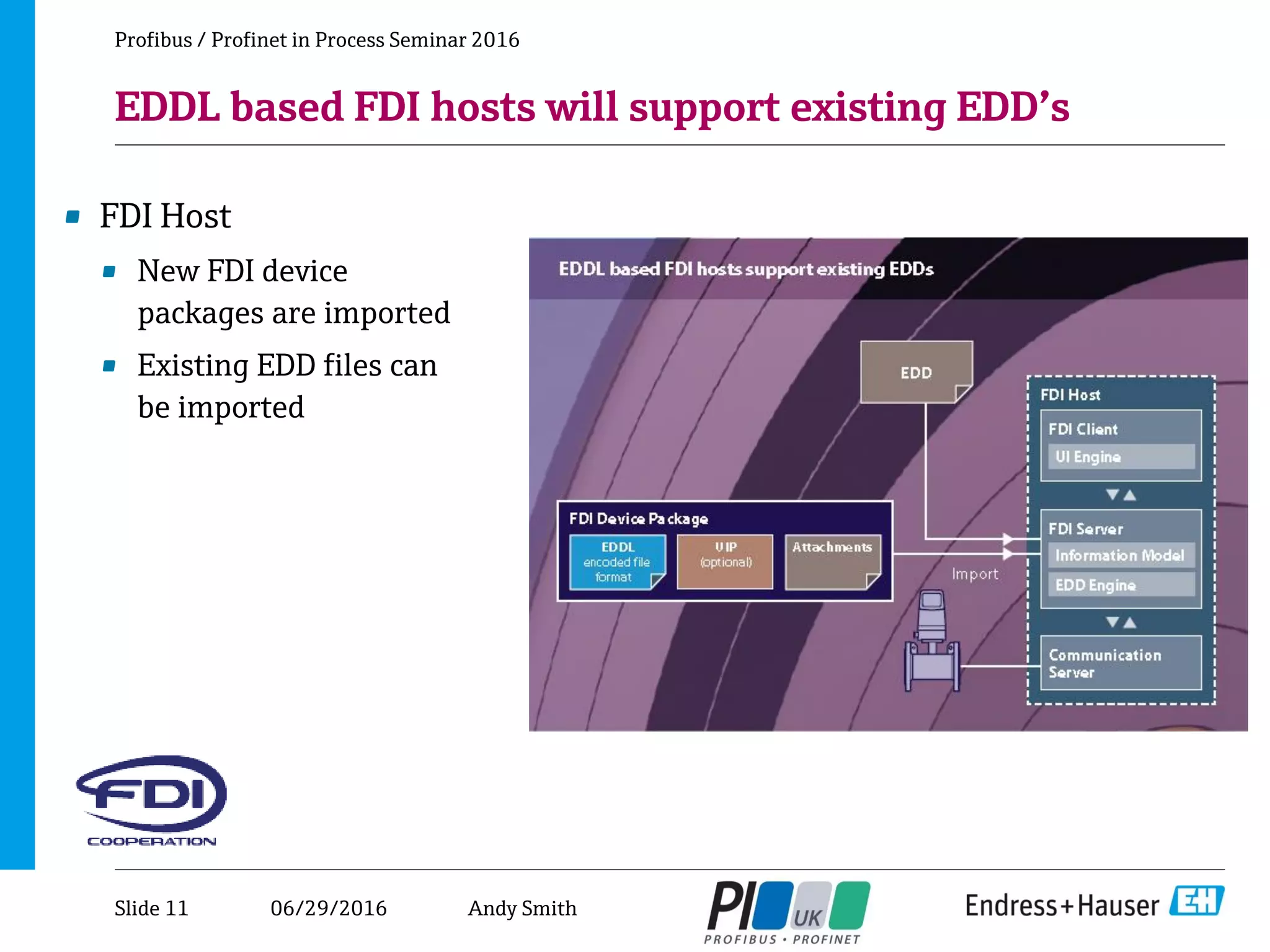

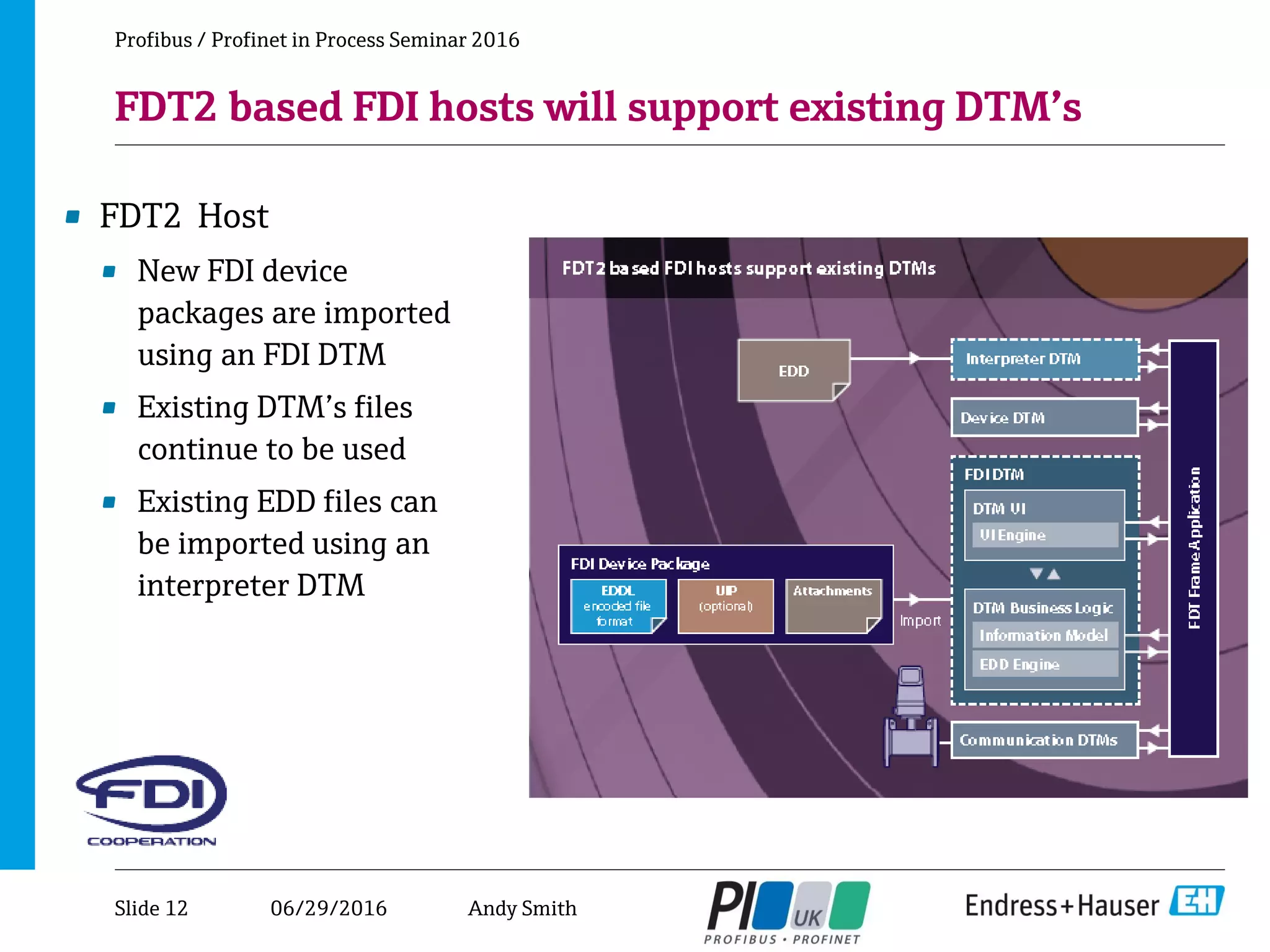

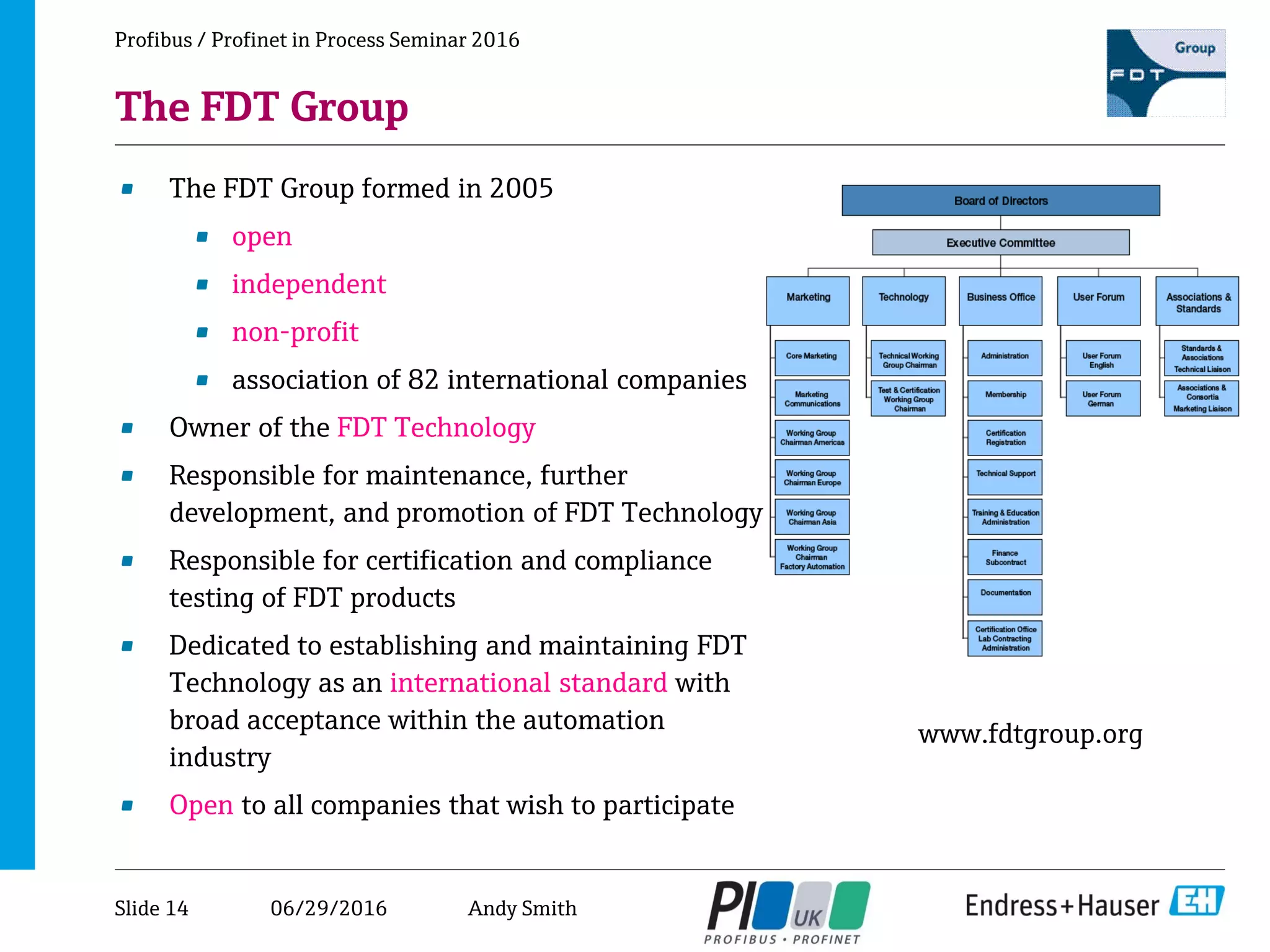

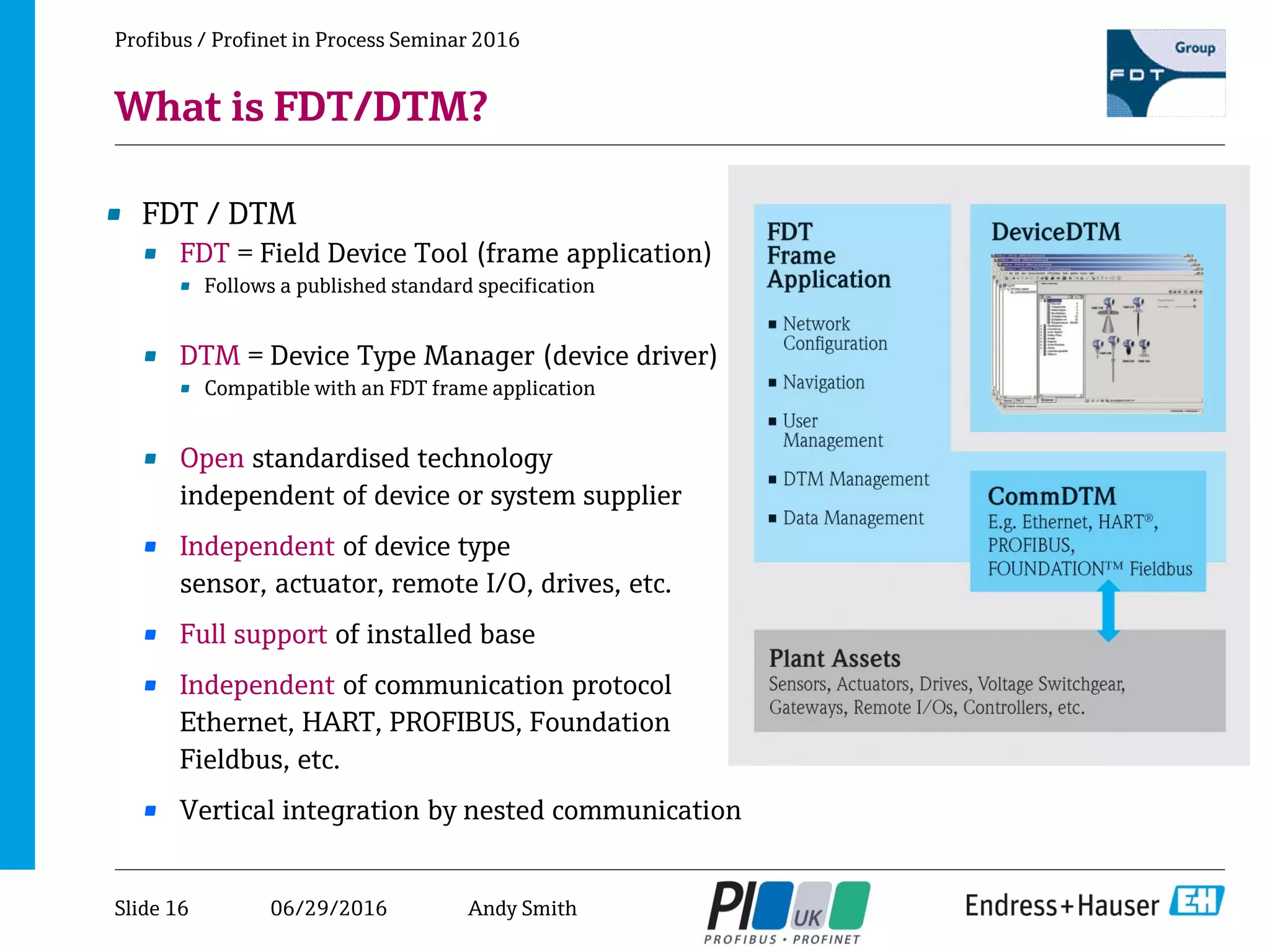

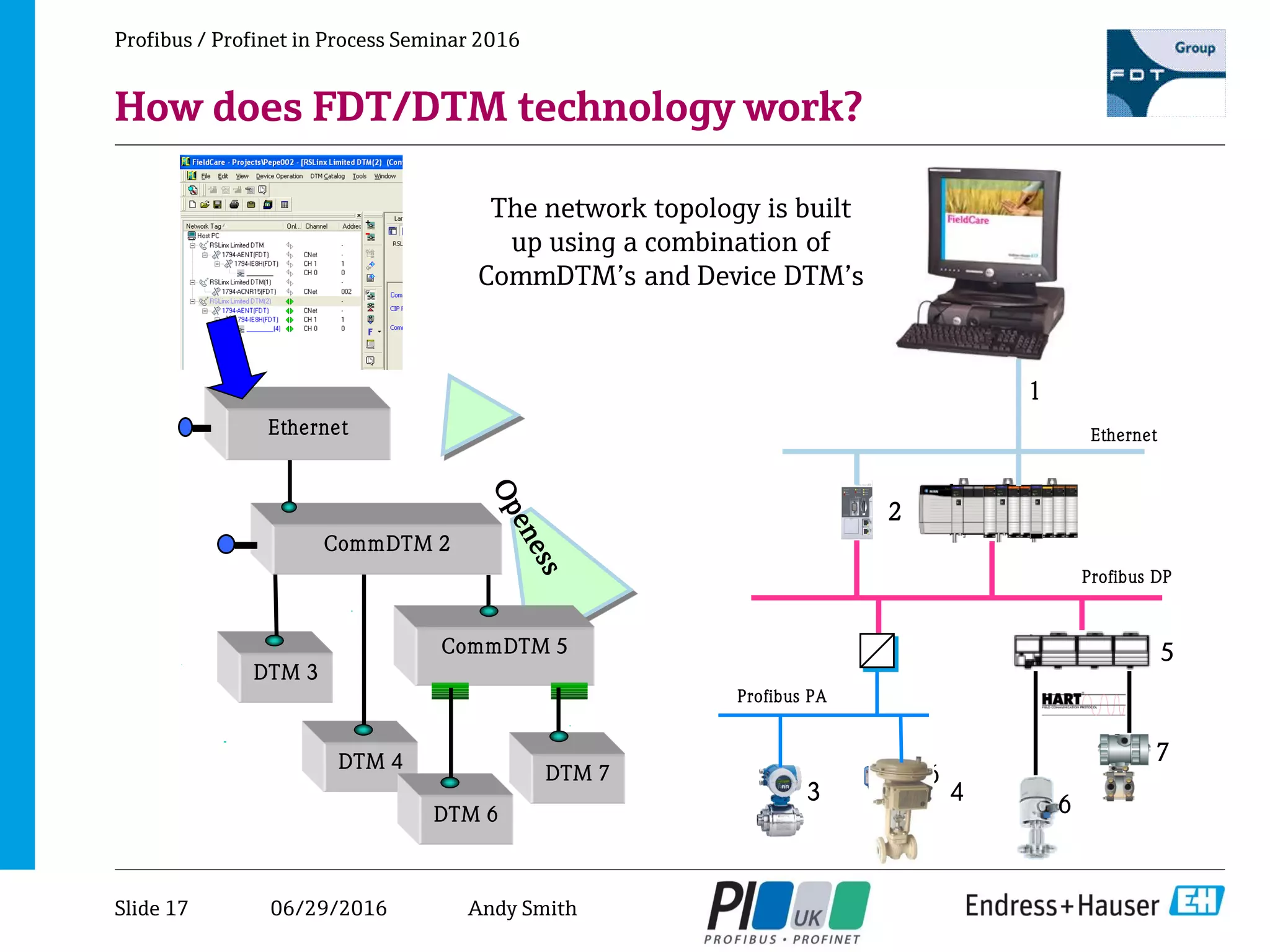

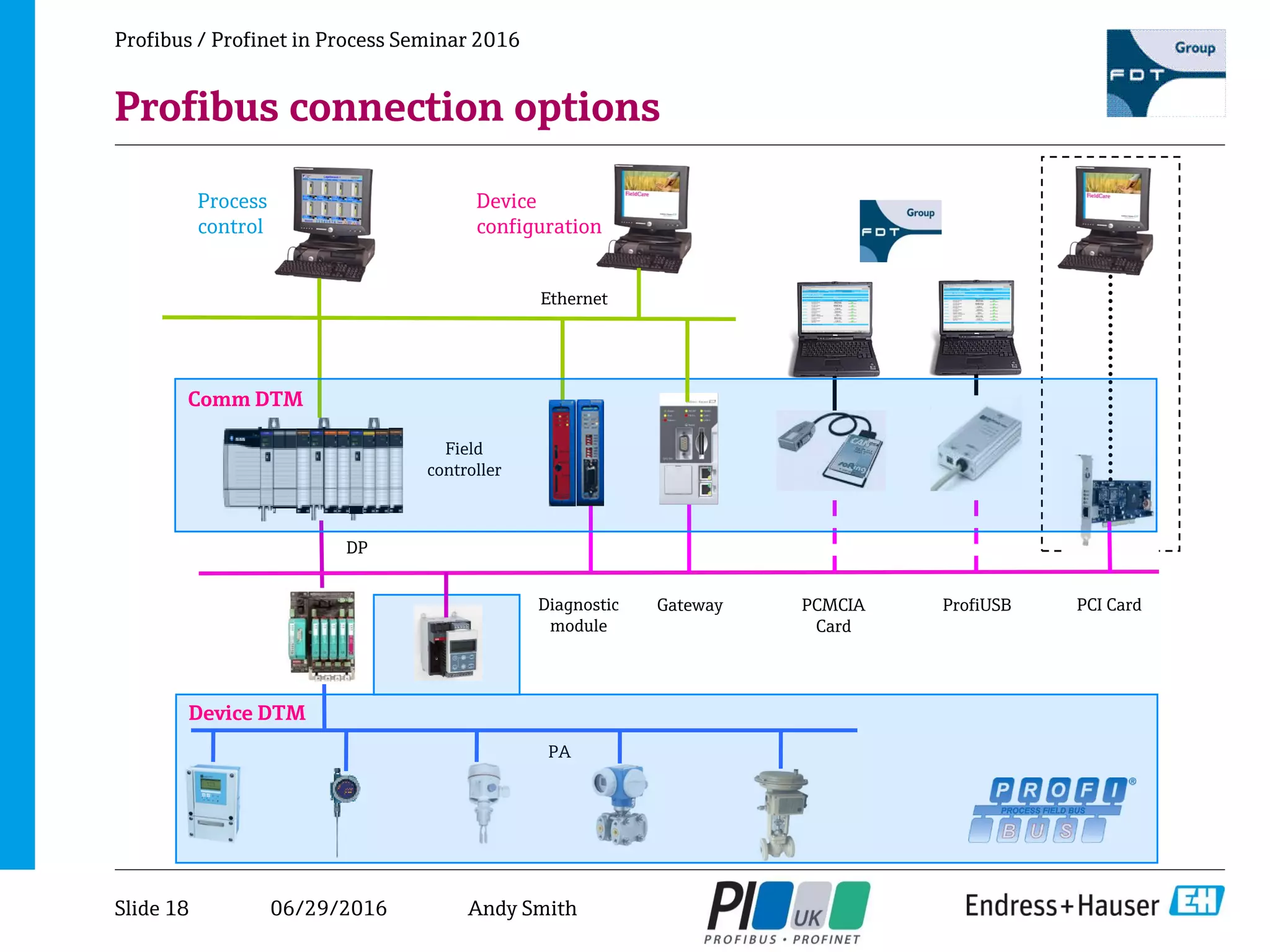

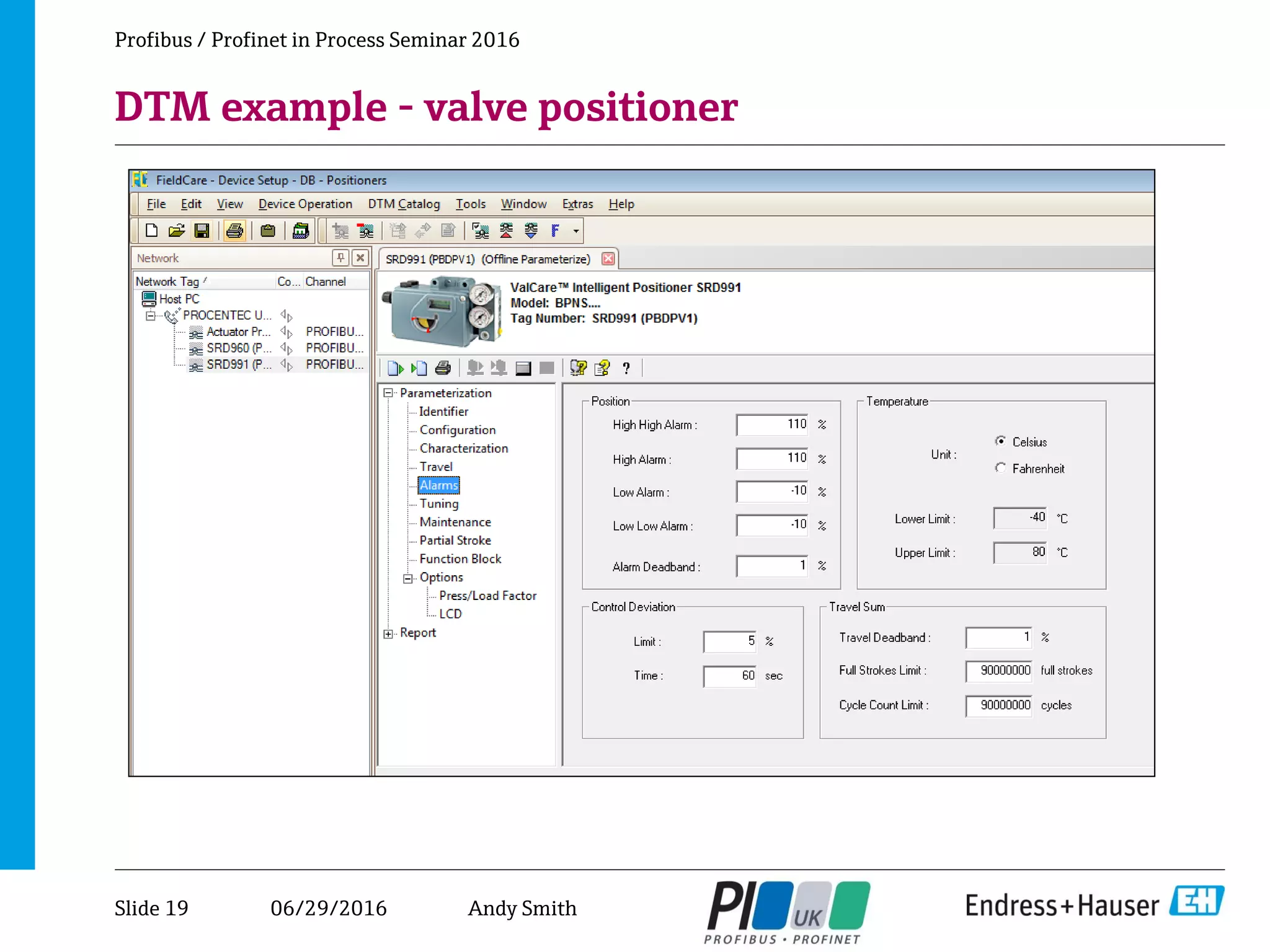

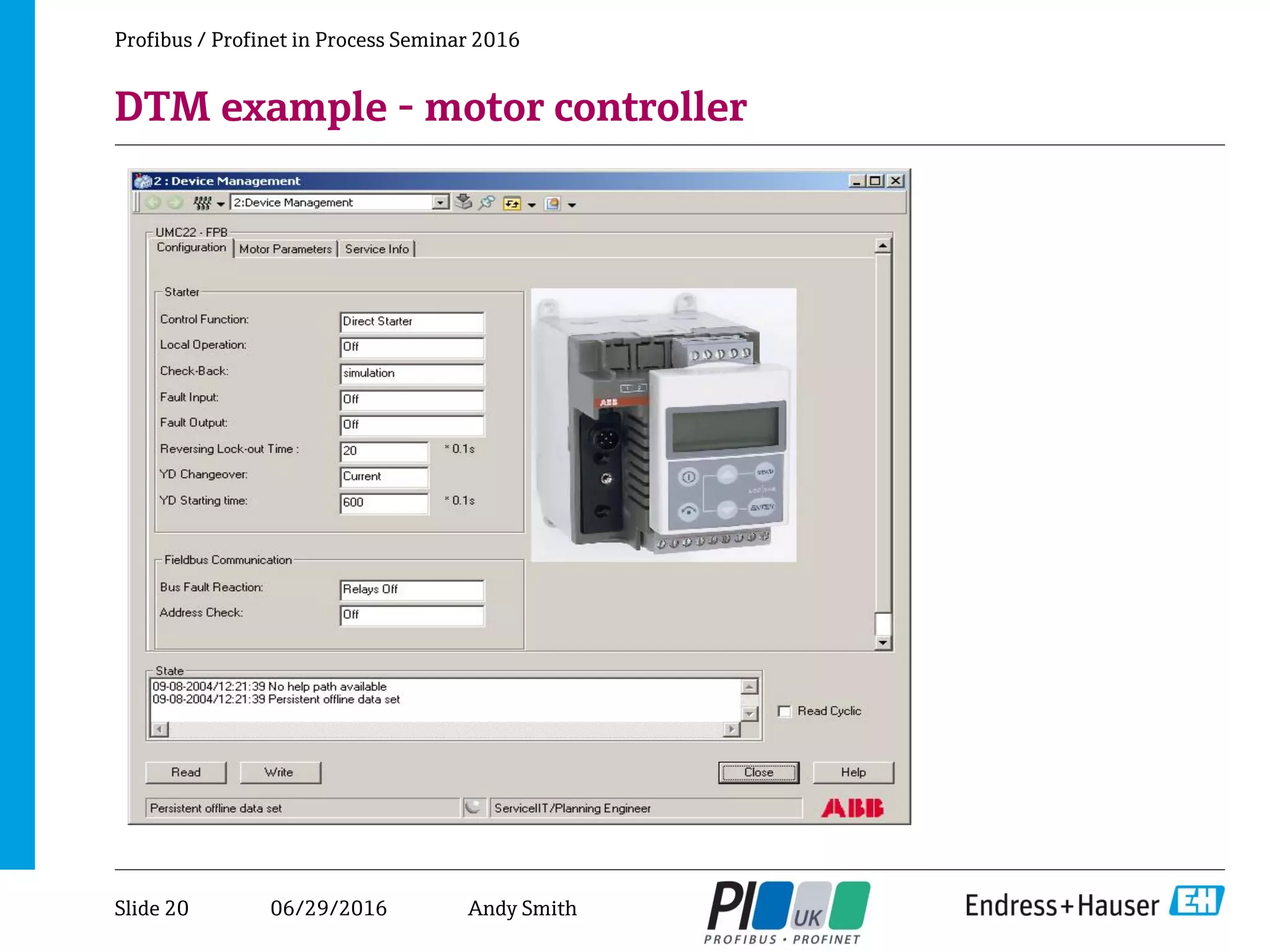

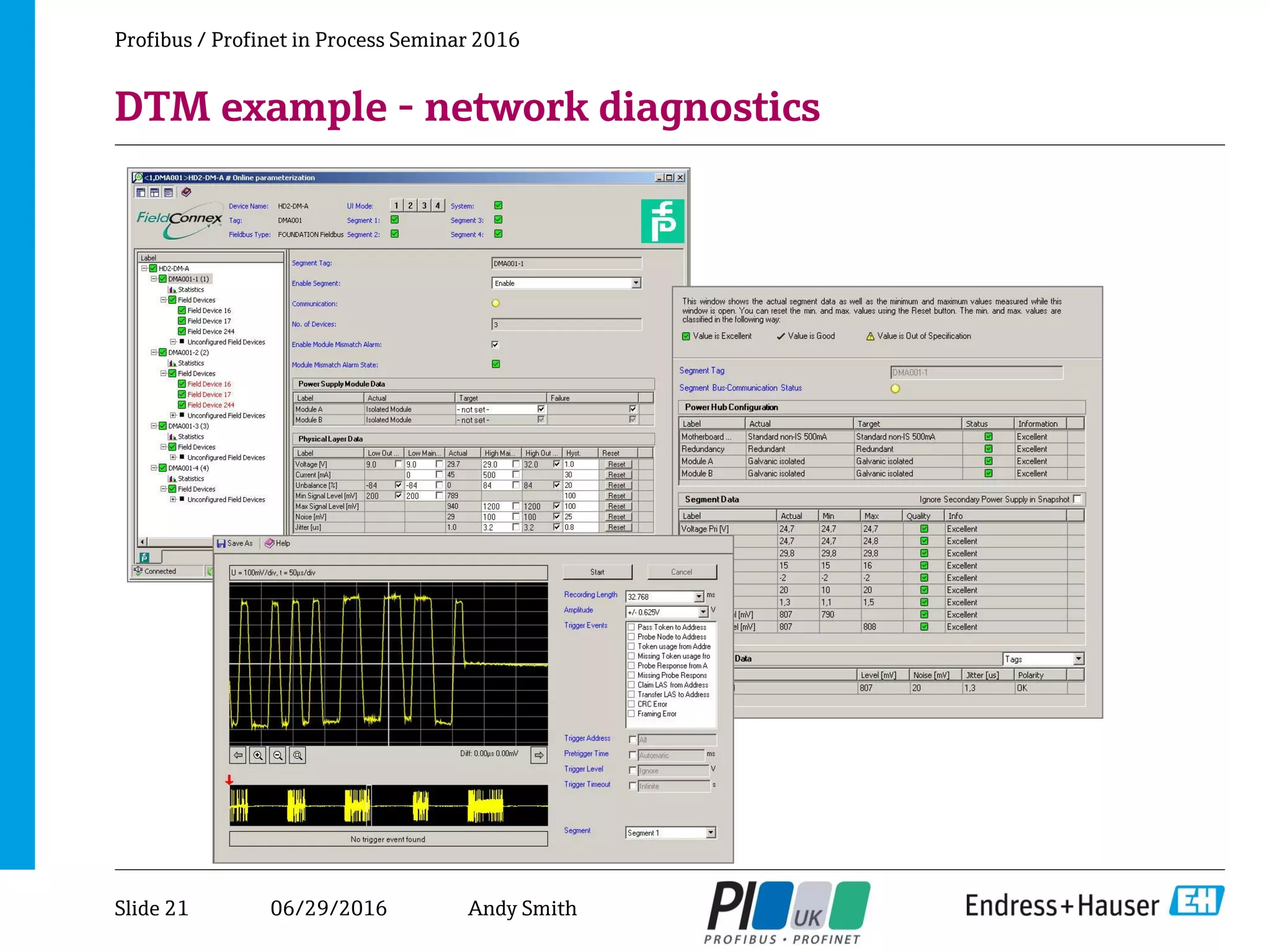

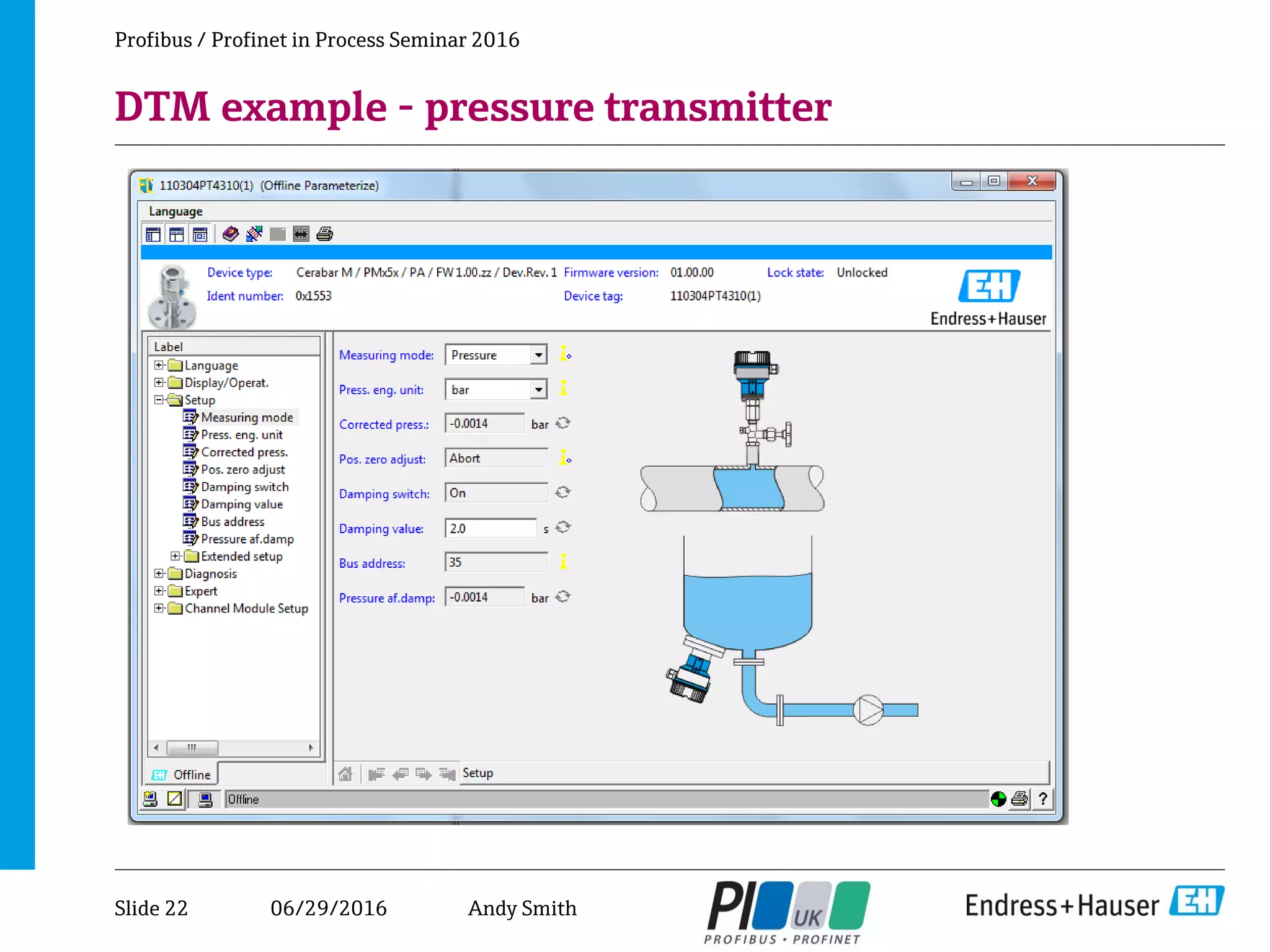

This document summarizes Andy Smith's presentation on configuring Profibus and Profinet devices. The presentation covers the history of device configuration tools including EDDL, FDT, and FDI. It also demonstrates configuring Profibus devices over ProfiUSB and Ethernet gateways as well as Profinet devices via an FDT frame and web browser interface. A live demo is included to showcase configuration of Profibus PA devices and Profinet devices.