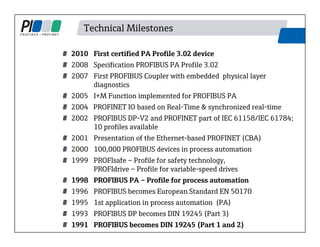

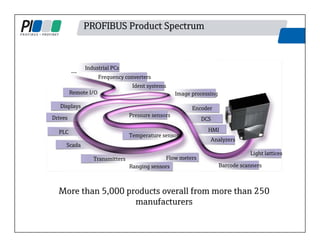

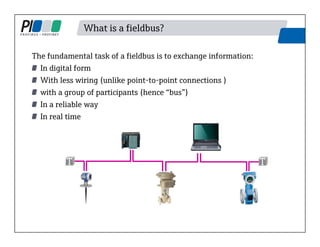

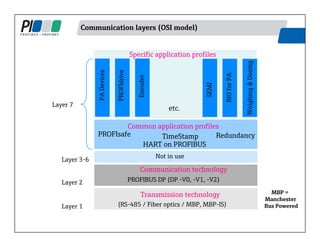

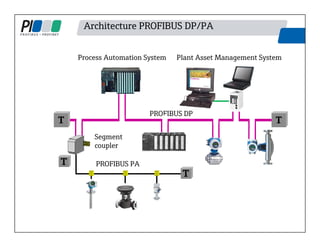

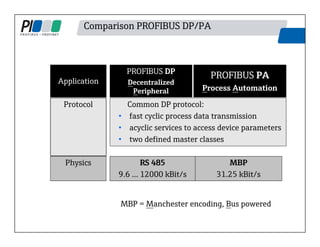

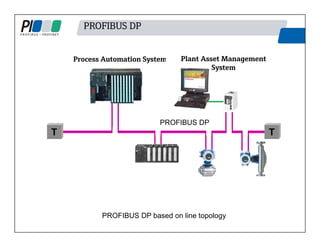

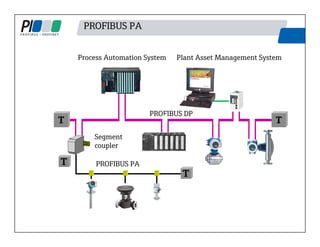

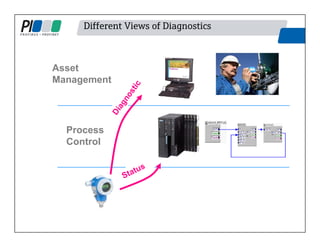

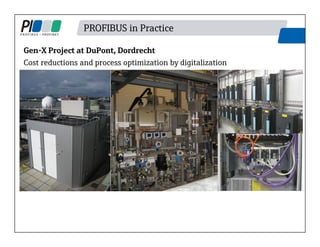

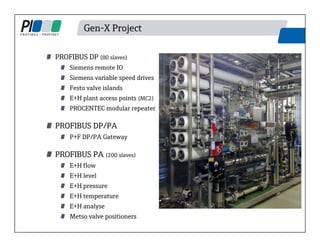

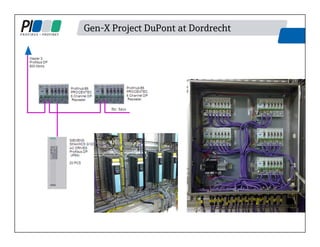

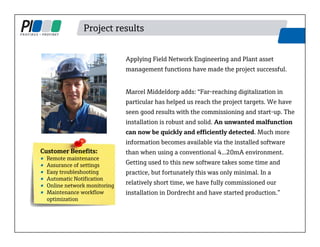

PROFIBUS is a widely adopted fieldbus standard used in industrial automation with over 40 million devices installed. The Gen-X project at DuPont's Dordrecht plant utilized PROFIBUS DP and PA networks along with plant asset management software to achieve a highly available automated system. Digitalization and network diagnostics solutions helped ensure a robust installation and efficient fault detection, resulting in successful commissioning and production start-up for the customer.