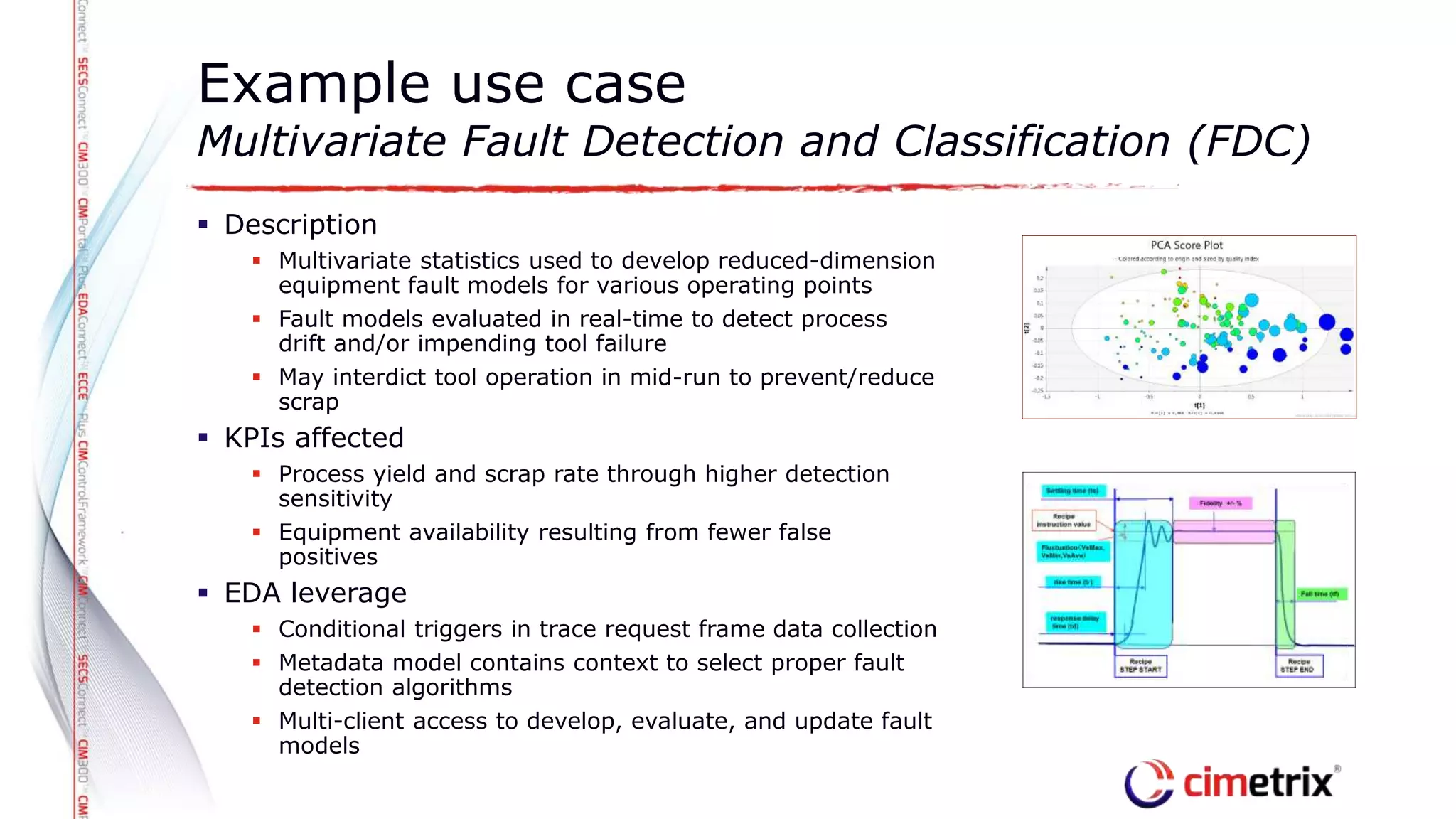

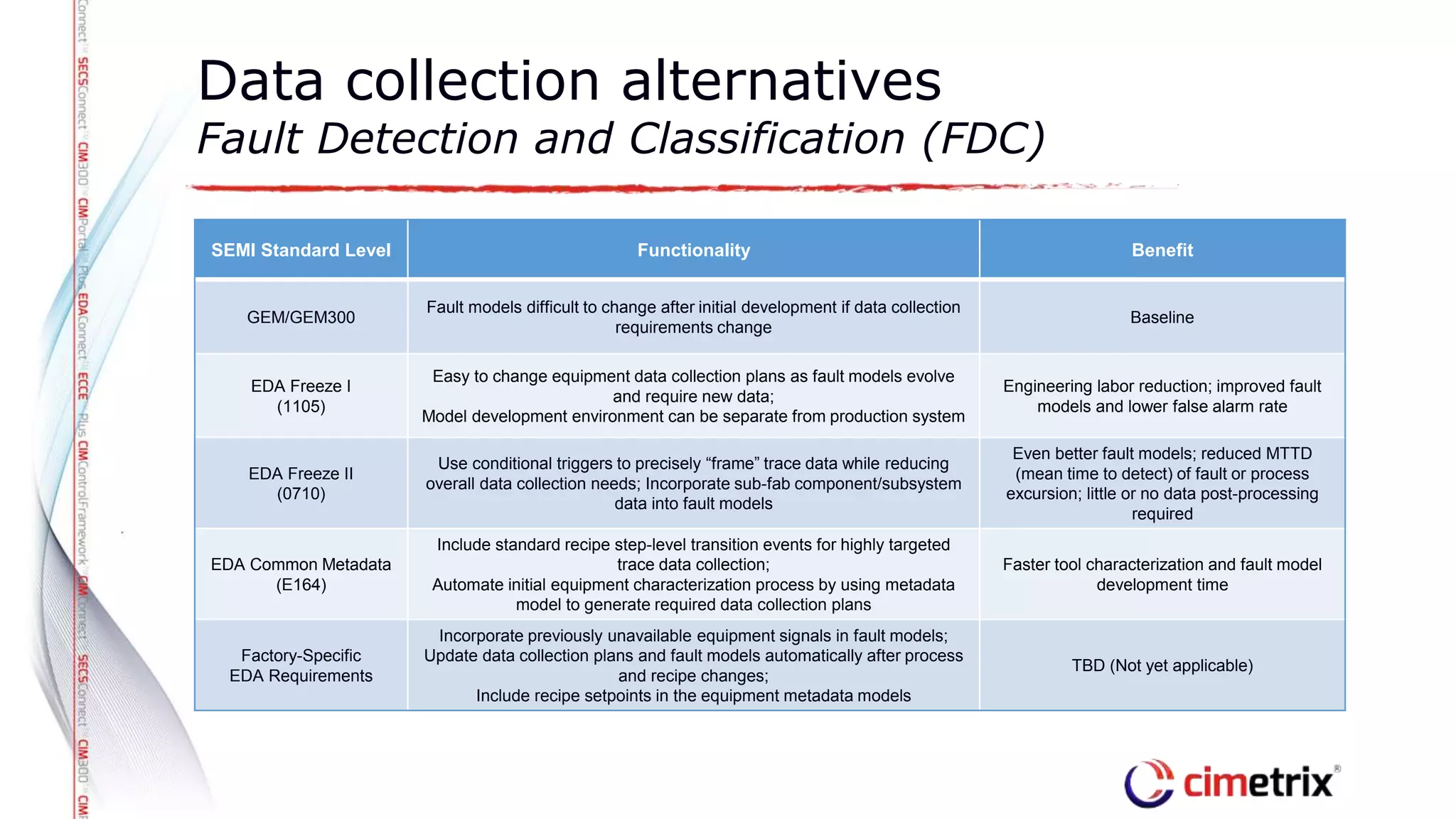

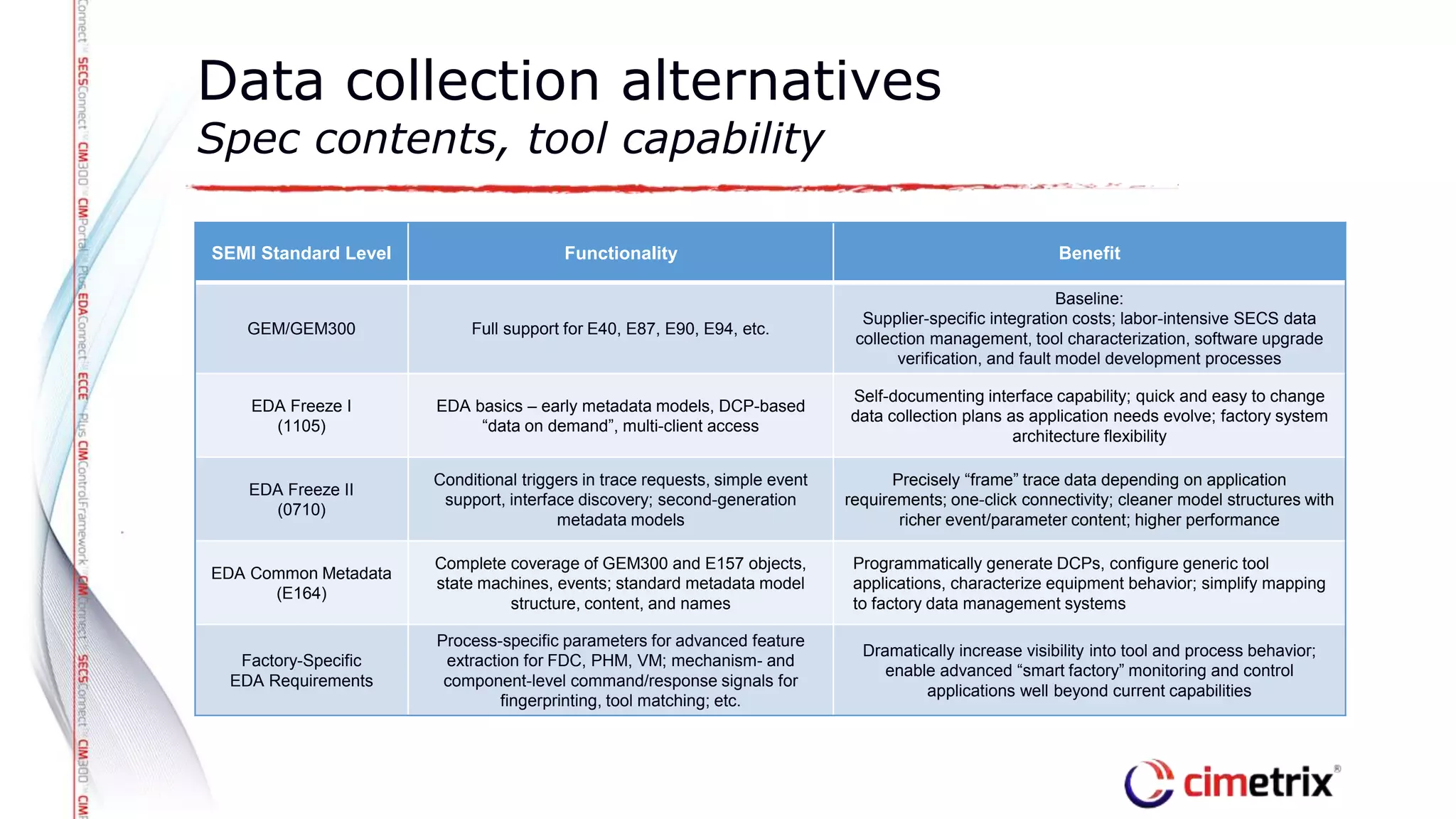

The document discusses the benefits of using SEMI's Equipment Data Acquisition (EDA) standards for smart manufacturing applications. It describes how EDA standards can help factories collect the right equipment data to develop multivariate fault detection models, which use real-time sensor data to detect process drift and tool failures. The metadata models in EDA Freeze II and EDA Common Metadata standards provide context to select the proper fault detection algorithms and allow data collection plans to be changed flexibly as fault models evolve.

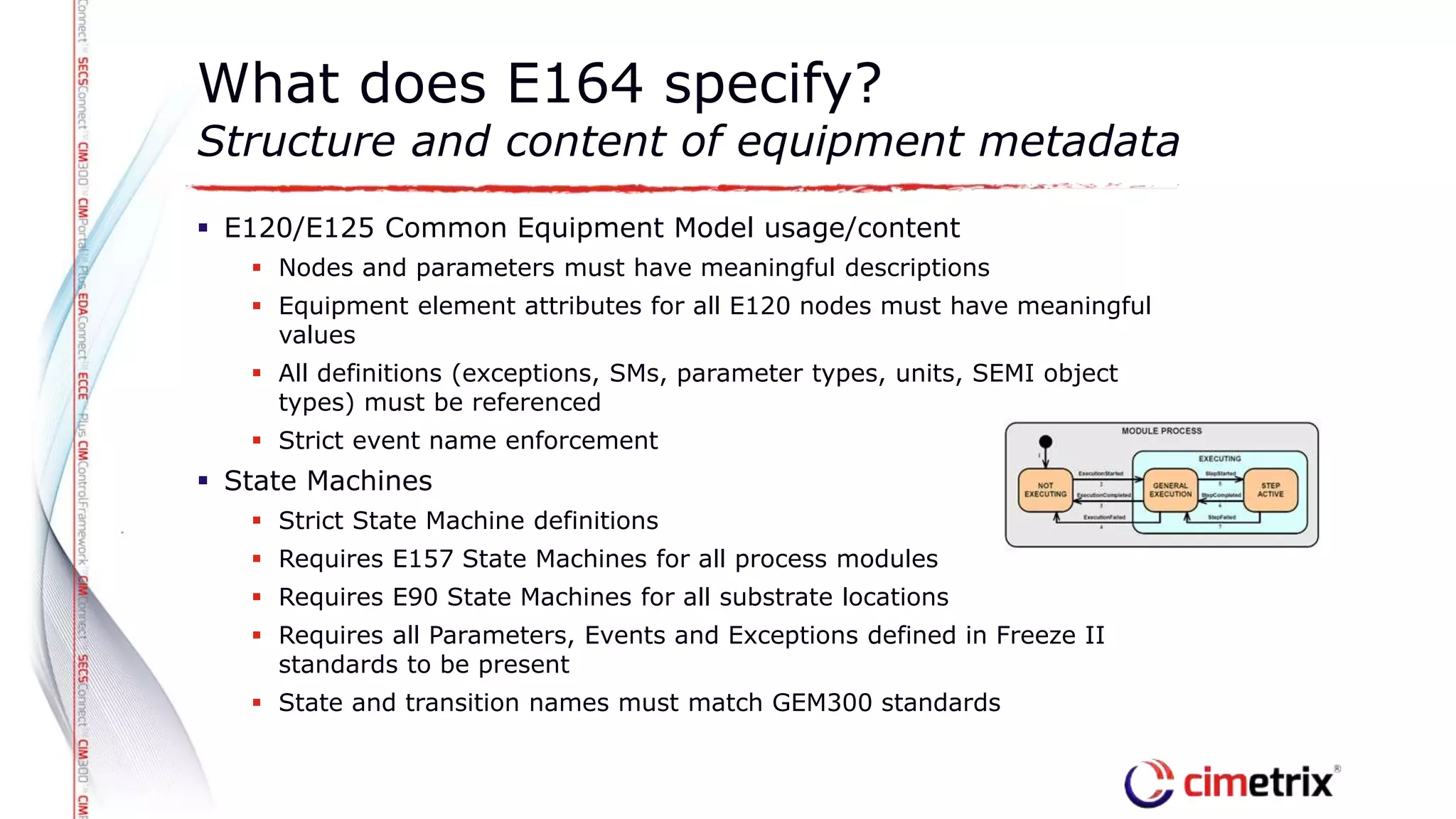

![ Model structure exactly reflects tool

hardware organization

Complete description of all potentially

useful information in the tool

Always accurate, always available – no

additional documentation required

Common point of reference among tool,

process, and factory stakeholders

Source of unambiguous identifiers/tags

for database [auto] configuration

Enables “plug and play” applications

Standard metadata model benefits

First specified by SEMI E164

Process Module #1

Gate Valve Data

Substrate Location

Utilization

More Data,

Events, Alarms

Process Tracking

Other

Components](https://image.slidesharecdn.com/weberedaapplicationsandbenefitsfinal-180606204107/75/EDA-Applications-and-Benefits-for-Smart-Manufacturing-14-2048.jpg)