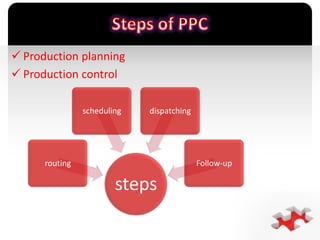

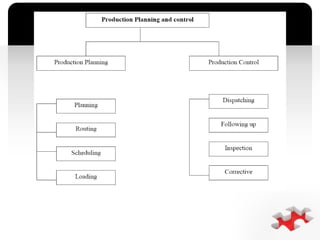

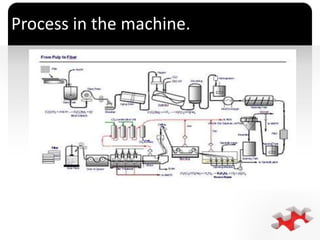

This document discusses production planning and control. It was presented by SYBMS students to Venkatesh Bugdi and coordinated by Varun Modi, Pranita Shinde, Dimple Shah, and Foram Rathod. The document outlines the importance of production planning, covers the processes of routing, scheduling, dispatching, and follow-up, and discusses how this leads to steady production flow and meeting delivery schedules.