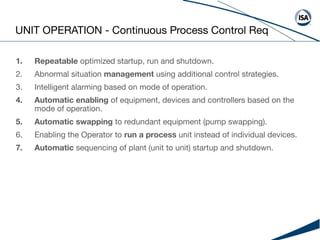

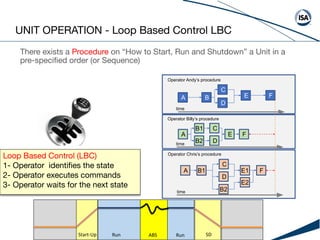

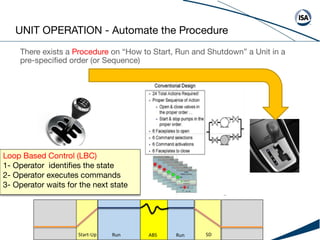

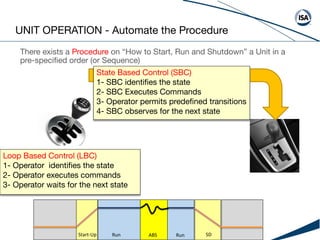

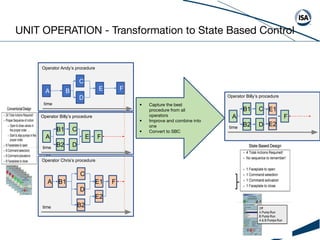

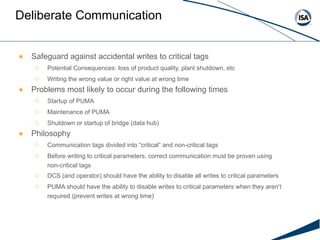

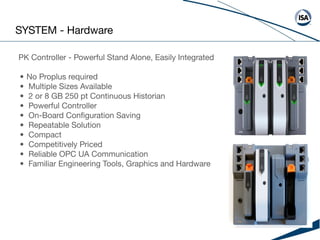

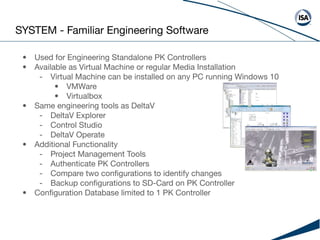

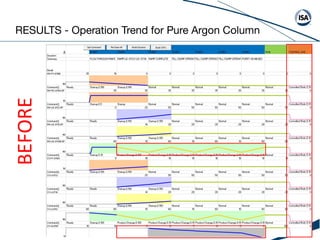

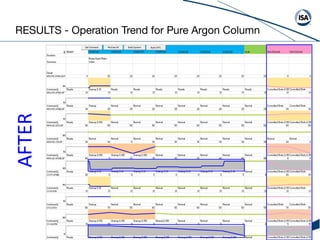

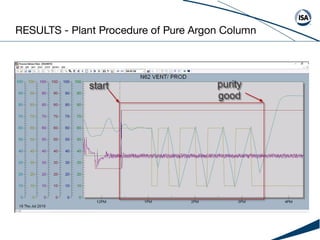

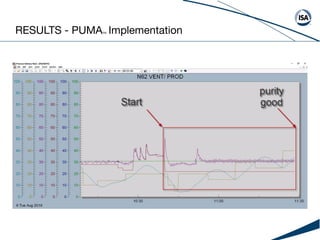

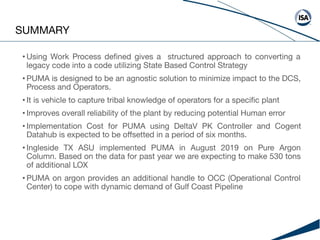

The document presents a framework for transforming continuous chemical process control from loop-based to state-based control, emphasizing automation and the integration of operator knowledge. It highlights the benefits of structured implementation, improved reliability, and reduced human error through the PUMA system, which has already shown promising results in a recent plant trial. Key technical aspects and networking strategies are discussed, along with references for further information.