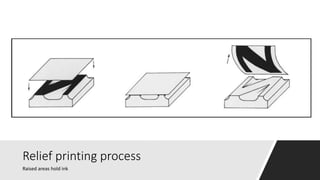

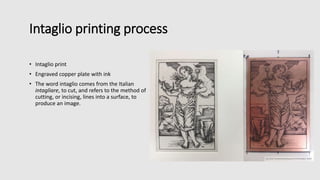

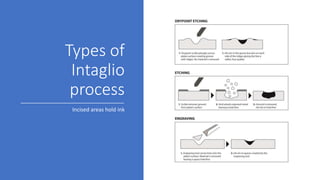

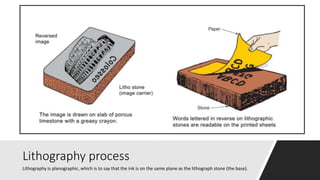

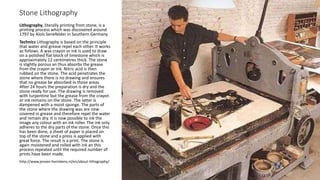

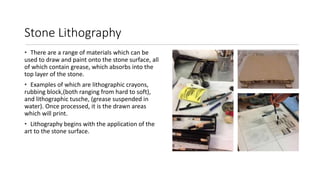

Relief printing involves inked raised surfaces that transfer ink to paper. Woodcut is a relief process where inked wooden blocks transfer images. Intaglio inks incised lines on copper plates to transfer images. Lithography uses grease-based drawings on limestone plates and water to transfer images in a planographic process. Pochoir uses stencils to apply color or patterns by pressing ink through cutouts onto surfaces. It was popular in graphic design in the early 20th century.