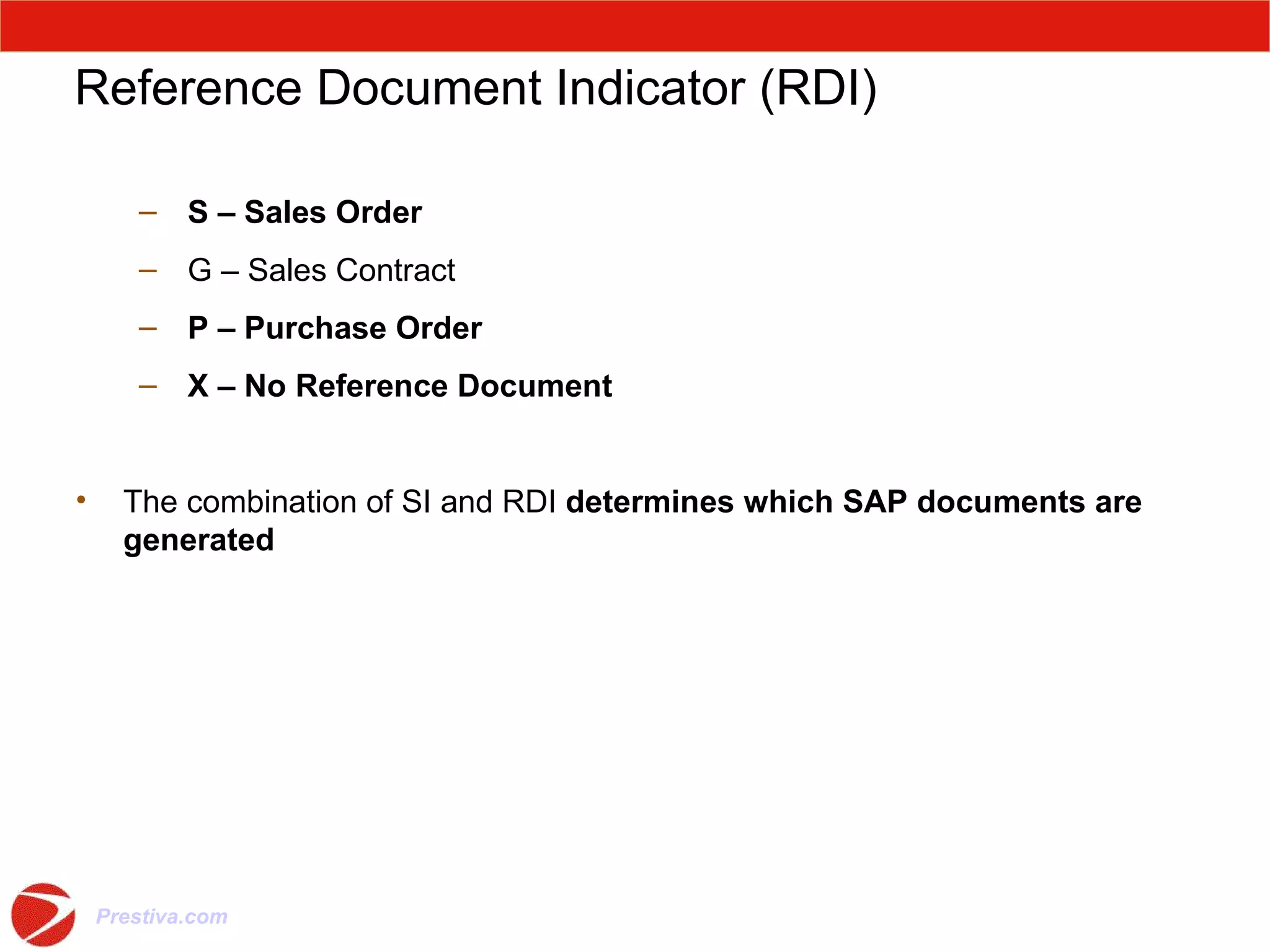

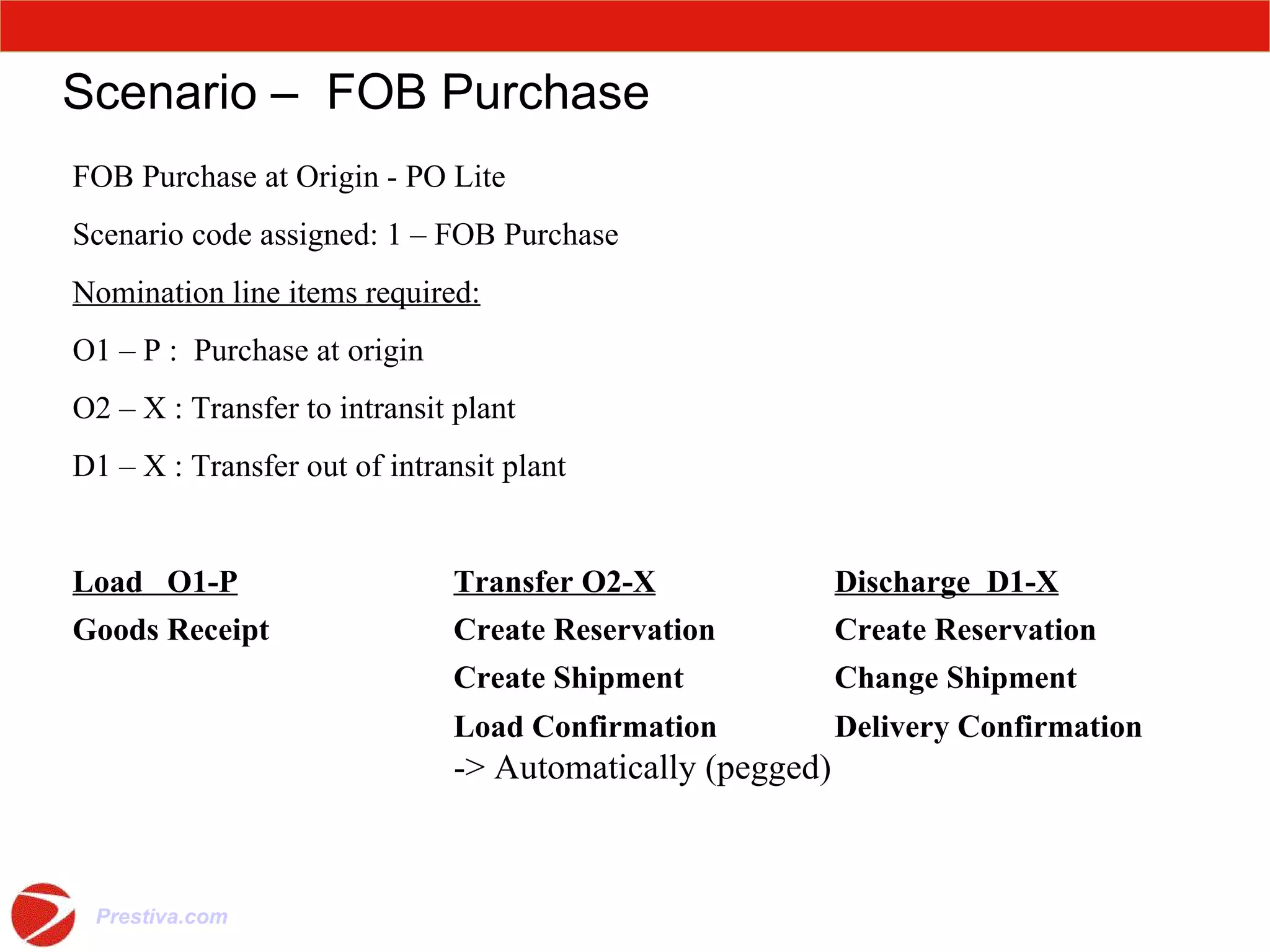

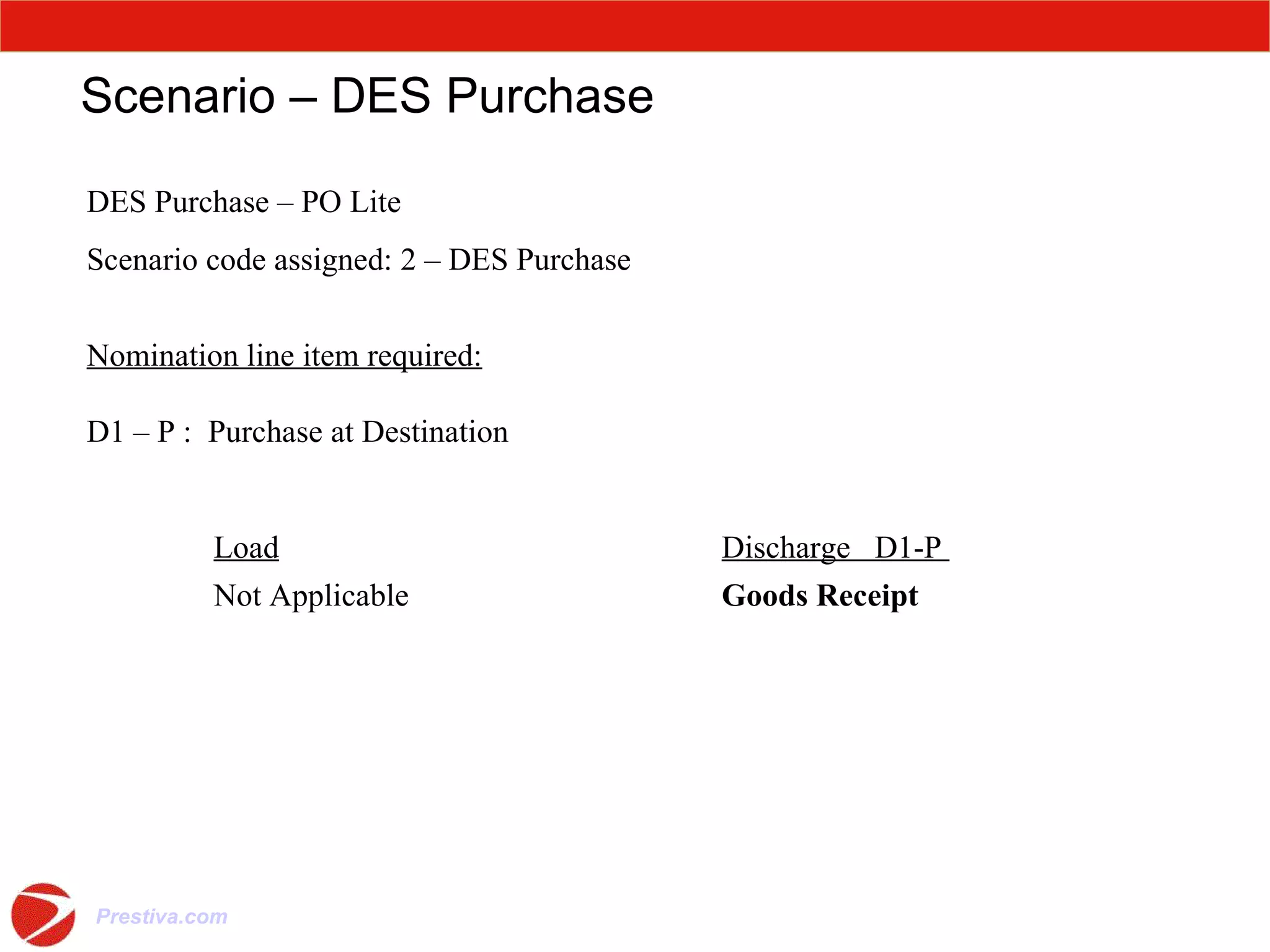

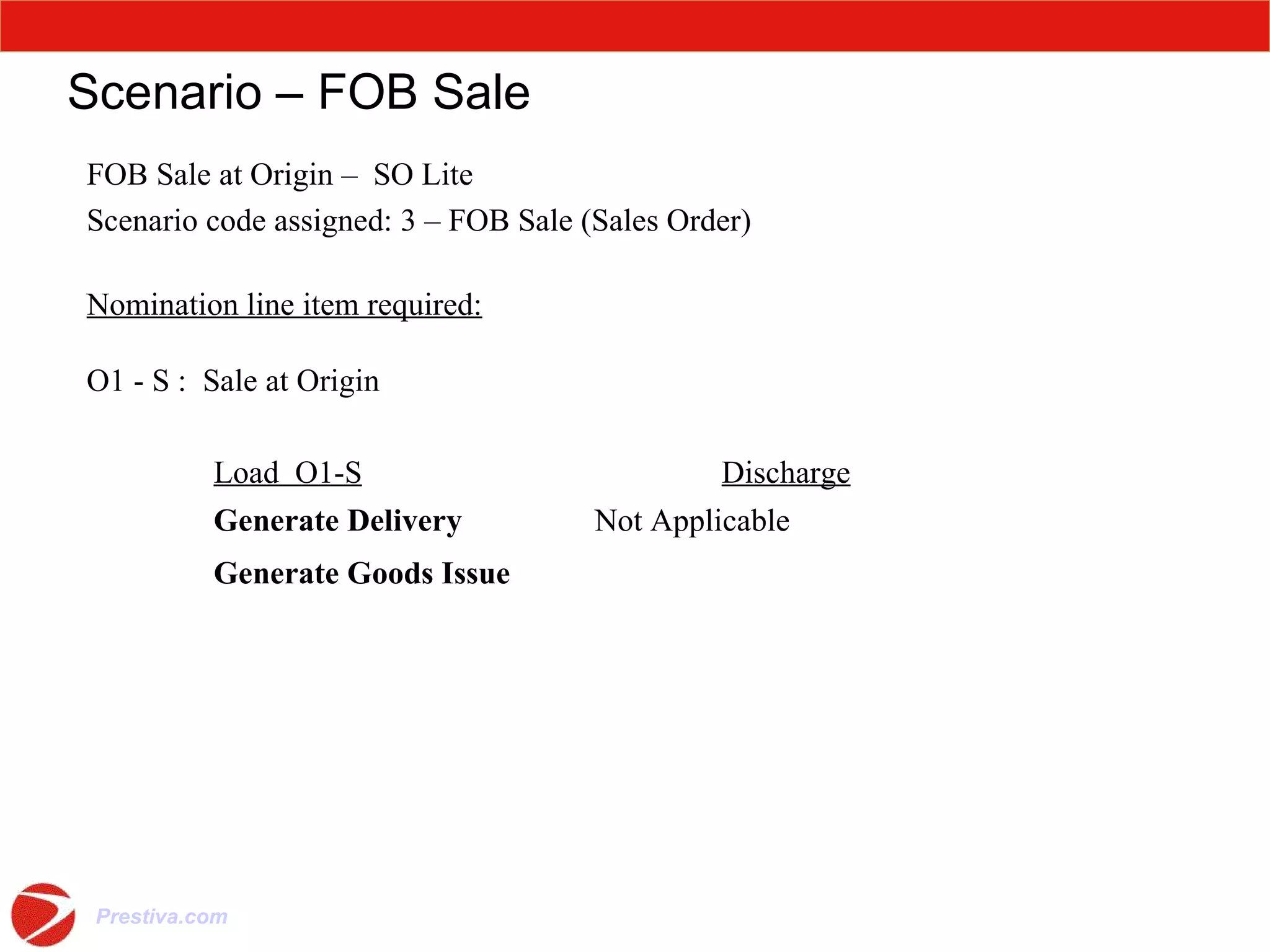

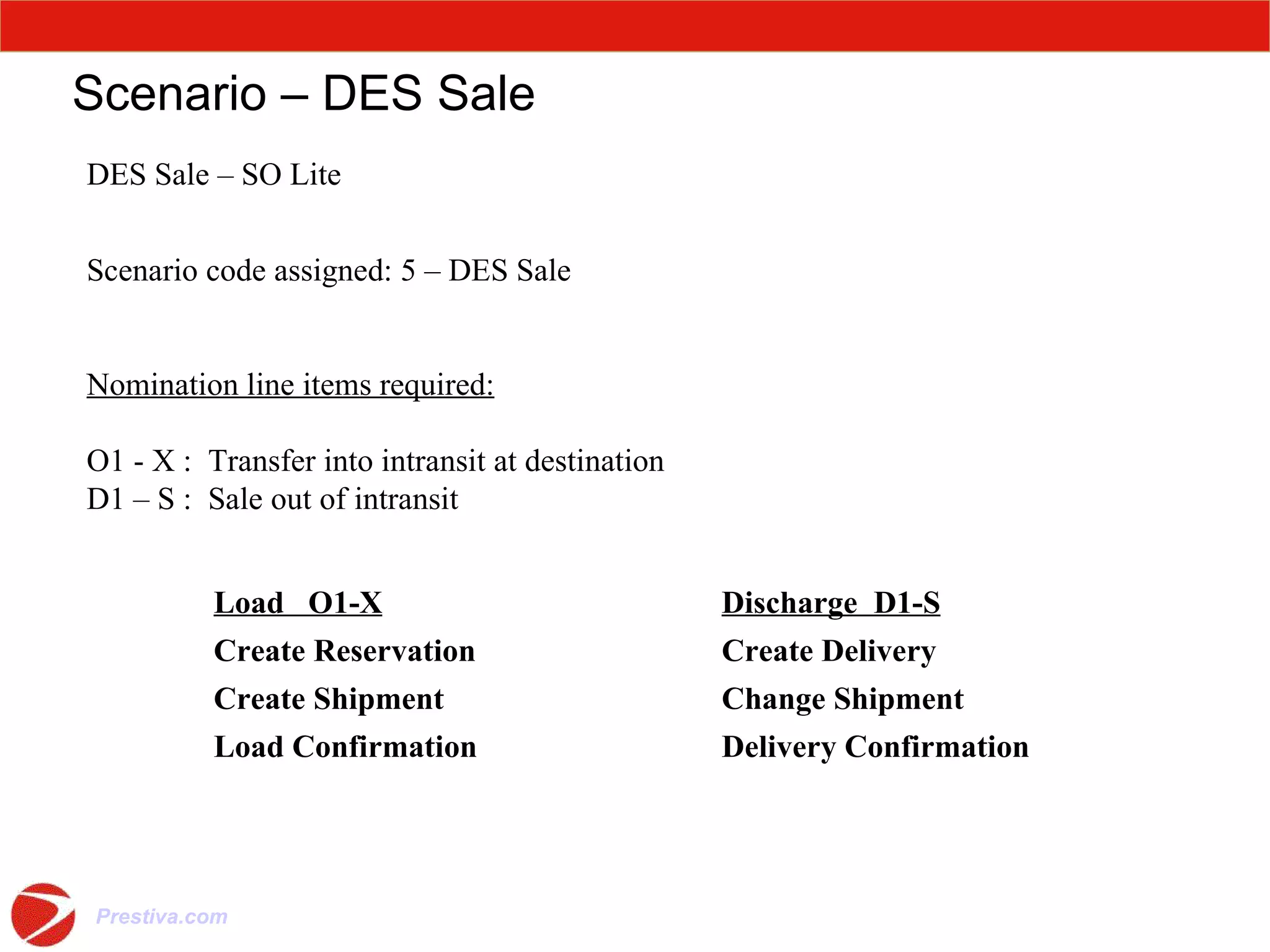

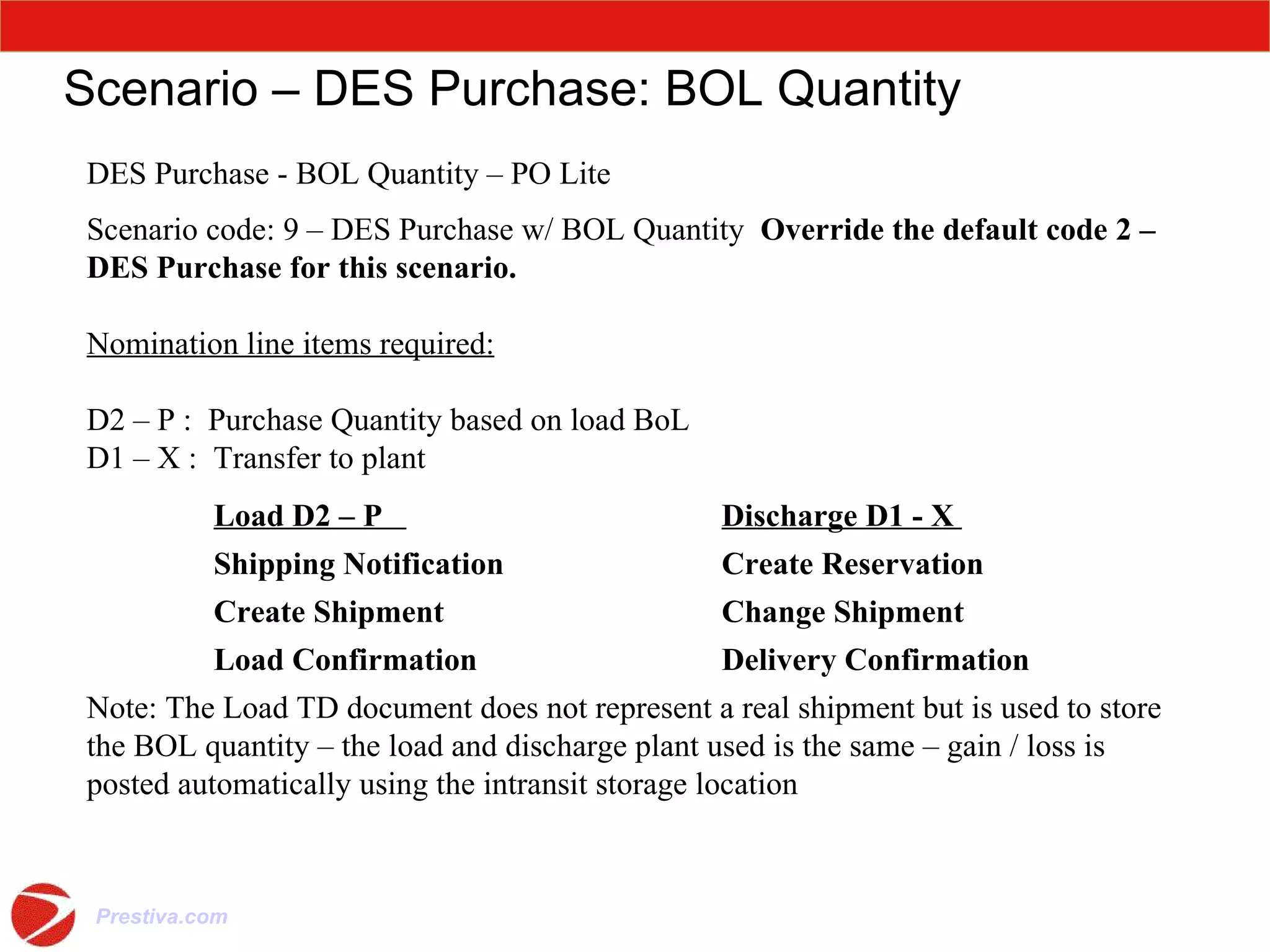

This document discusses oil movement nomination scenarios in SAP. It describes the six basic movement scenarios including FOB purchase, DES purchase, FOB sale, DES sale, and DES purchase with BOL quantity. It explains how the schedule item type and reference document indicator determine the scenario and documents generated. The document also covers topics like pegging, creating nominations, searching for nominations, and learning checkpoints.