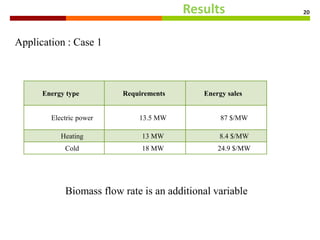

The document presents a thesis defense by Chantal Chemaly at the Université Libanaise, focusing on the tri-generation of heat, cold, and electricity from biomass. It outlines the methodology, results from a sensitivity study, and future applications of the research, highlighting the efficiency and economic benefits of such systems. Key findings include energy production data, cost implications, and suggestions for further studies regarding greenhouse gas emissions and operational efficiencies.