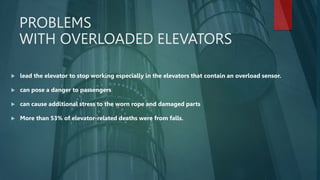

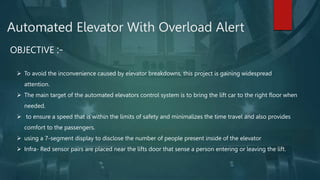

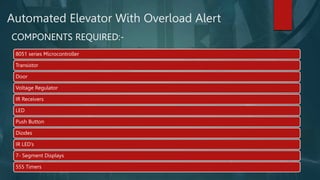

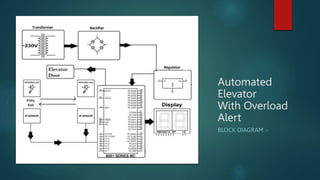

This document describes a proposed automated elevator system with overload alert. The system uses infrared sensors and a microcontroller to detect the number of passengers entering and leaving the elevator. A 7-segment display shows the current passenger count. An alarm buzzes if too many passengers enter. The goal is to prevent elevator breakdowns from overloading and ensure passenger safety. Components include a microcontroller, sensors, displays and buzzers. Flow charts show the logic and block diagrams illustrate the system design. Simulation and testing showed the system working as intended to accurately count passengers and alert if limits are exceeded.

![REFERENCES

[1] ÁKOS BECKER, DEPARTMENT OF ELECTRONICS TECHNOLOGY, BUDAPEST

UNIVERSITY OF TECHNOLOGY AND ECONOMICS, BUDAPEST, HUNGARY

[2] CHEAH, SIEW HOON (2006) MICROCONTROLLER BASED LIFT CONTROL SYSTEM.

FACULTY OF ELECTRICAL & ELECTRONIC ENGINEERING, UNIVERSITY MALAYSIA

PAHANG.

[3] POORVI BEHRE, VIVEKA NEMA, AND BHUPENDRA BADONIYA, CONGESTION-FREE

ELEVATOR CONTROL USING MICROCONTROLLER, INTERNATIONAL JOURNAL OF

SCIENTIFIC & ENGINEERING RESEARCH VOLUME 4, ISSUE 1, JANUARY-2013 1, ISSN

2229-5518.

[4] MUHIBUL HAQUE BHUYAN, MD. MAIDUL HAQUE, M. ABDUR RAUF AND MD.

MAZHARUL ISLAM KHAN DEPARTMENT OF ELECTRICAL AND ELECTRONIC

ENGINEERING DAFFODIL INTERNATIONAL UNIVERSITY, SHUKRABAD, DHAKA,

BANGLADESH DEPARTMENT OF](https://image.slidesharecdn.com/presentation5-230921115012-41c8e9ea/85/Presentation-5-pptx-12-320.jpg)