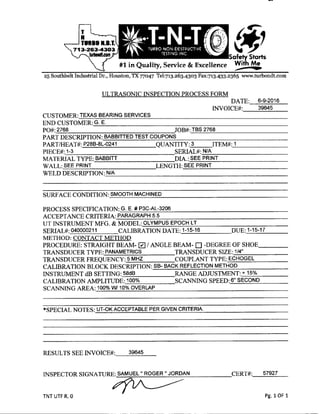

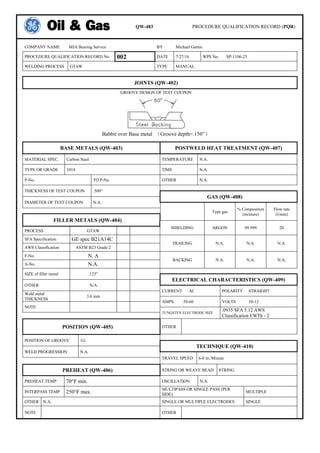

This document is a Welder Performance Qualification Record that qualifies welder Michael Gartee to perform repair welding according to procedure QR-M-Bearing-001. It details the welding process, material, and examinations and tests performed, including visual inspection, penetrant testing, macro testing, and bend testing, all of which were found to be acceptable. The welder is considered qualified to perform repair welding according to the requirements and limitations of the procedure.

![QW-483 (BACK) PQR No. 001

TENSILE TEST (QW-150)

SPECIMEN No. WIDTH mm THICKNESS mm AREA mm2

ULTIMATE

TOTAL LOAD

(N)

ULTIMATE

UNIT STRESS

N/mm2

TYPE OF

FAILURE &

LOCATION

N. A.

GUIDED-BEND TEST (QW-160)

TYPE AND FIGURE No. RESULT

SIDE BEND [507-1] ACCEPTABLE

TOUGHNESS TEST (QW-170)

SPECIMENT

No.

NOTCH

LOCATION

NOTCH TYPE TEST TEMP.

IMPACT

VAL.

LATERAL EXPANSION DROP WEIGHT

% SHEAR MILS BREAK NO BREAK

N.A.

COMMENTS: N.A.

FILLET-WELD TEST (QW-180)

RESULT-SATISFACTORY: YES - NO - PENETRATION INTO PARENT METAL: YES - NO -

MACRO-RESULT Pass no detection of defects

OTHER TESTS

TYPE OF TEST & RESULT Ultrasonic and Dye Penetrant testing ( Pass )

DEPOSIT ANALYSIS

OTHER

CLOCK No. N.A - STAMP No. 002WELDER’S NAME Michael Gartee

TEST CONDUCTED BY: ARC Specialties LABORATORY TEST No. 507-1

WE CERTIFY THAT THE STATEMENTS IN THIS RECORD ARE CORRECT AND THAT THE WELDS WERE PREPARED, WELDED, AND

TESTED IN ACCORDANCE WITH THE REQUIREMENTS OF GE SPEC & SECTION IX OF THE ASME BOILER AND PRESSURE VESSEL

CODE.

MANUFACTURER APPROVED

BY MJA Bearing services BY

DATE 7/27/16](https://image.slidesharecdn.com/1b1ccc07-97ea-4c01-8f2d-f445ae4f95f4-161230135701/85/GTAW-Qualification-Michael-Gartee-2-320.jpg)