PPT_PMI- R2.pptx

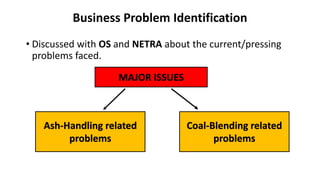

- 1. Business Problem Identification • Discussed with OS and NETRA about the current/pressing problems faced. MAJOR ISSUES Ash-Handling related problems Coal-Blending related problems

- 2. Mr. A K Tripathi (AGM, Senior Faculty) Mr. Sujoy Karmakar (AGM) Mr. Kumar Swadhin (AGM) Mr. Dilip Kumar (AGM & HOD, Boiler) Mr. A K Samaiyar (AGM, Boiler) Mr. Anjan Sinha (AGM) Mr. Sneh Banerjee (AGM, EEMG) Mr. Himanshu Chaturwedi (AGM, EEMG) Discussions for Problem Identification PMI NETRA OS EEMG (STATIONS)

- 3. Discussions for Problem Identification • Coal-Blending problem was chosen for study • Coal related problems more wide spread. • Challenges with Ash-Handling: Very plant specific. More difficult to analyze (Two phase flow). Work requires lots of site’s operational data.

- 4. Why Coal-Blending • Coal-fired power plants are designed to burn coal with defined characteristics. • Over time, the accessibility of coals change and coals may become less available. • To meet the shortfalls different types of coals may be required to be blended Imported Coal Blended with Indigenous Coal. Blending of indigenous coals may also be required.

- 5. Possible advantages of coal-blending for the power plants are: 1. Reducing fuel costs. 2. Controlling emission limits. 3. Enhancing fuel flexibility and extending the range of acceptable coals. 4. Providing a uniform product from coal of varying quality. 5. Solving existing problems such as poor carbon burnout, slagging and fouling, and improving boiler performance. Coal-Blending Advantages

- 6. Coal Blending Issues Unpredictability in Boiler Performance • Coal-Blending brings unpredictability in Boiler Performance. • Blended coals performance may not be “interpolated linearly” from that of the parent coals. • Coal-Blends have two kinds of properties: Additive - Properties remain additive after blending, such as calorific value, volatile matter and ash content. Synergistic (non-additive) – Properties cannot be predicted by the additivity, such as ignition behaviour, burnout, unburned carbon, slagging, fouling and NOx emissions.

- 7. Coal Blending Issues Prediction of Parameters is Important • It is necessary to predict, as much as possible, the physical and economic challenges that will arise when switching coals. • Power plant operators must decide which parameters are most important in each plant. • Optimizing blending and boiler operations increase plant power output while reducing negative effects on the plant (such as corrosion and fouling) and potentially reducing emissions.

- 8. What We are exactly going to Study 1. Effect of coal-blending on performance, temperature profile and NOx formation in boiler. 2. Understand the cause of temperature imbalance in crossover pass. 3. Understand the cause of high temperature at SH and at flue gas exit (FEGT) for a particular mill combination. 4. Understand the cause of unburnt carbon in boiler.

- 9. Computational Modelling to Understand the Effect of Blending • Possible to use CFD models to understand and simulate the combustion behavior of blends. • CFD model allows the operating engineers to gain better understanding of underlying process and to carry out virtual experiments to evaluate new ideas. • A priori predictions of process performance with just the knowledge of geometry and operating parameters. • More efficient, economical and helps in understanding the relative contributions of each individual process.

- 10. Other Benefits of Computational Modelling • CFD model is useful in evaluating the influence of hardware configurations such as: Location and tilt of burners Swirl at burners. Location and configuration of internal heat exchangers. Air ingress. Heat transfer effectiveness. Imbalance in temperatures.

- 11. Computational Modelling Package being used for this project • Modelling and Analysis being done in (ANSYS-15.0): For modelling : is to be used. For analysis and post processing : is to be used. • Geometrical configuration of boiler & furnace is modelled in ANSYS-ICEM. • Actual physical processes and corresponding mathematical equations are modelled and solved in ANSYS-FLUENT. ANSYS-FLUENT ANSYS-ICEM

- 12. ANSYS Pre Requisites • The above software requires high computing speed. • High performance computing resources are available at IIT- Delhi and NETRA. • NETRA has 64-Core processer computing facility. • Working in collaboration with Professors at IIT-Delhi. • Reference book : “Computational Modeling of Pulverized Coal Fired Boilers” (Issued from IIT-Delhi library)

- 13. Selection of NTPC Unit for Study • Discussed with OS, NETRA and EEMG to select the units. • Selected units are: 1. UNCHAHAAR UNIT- 1 (210MW)- Selected for initial trials 2. VINDHYACHAL UNIT-7 (500MW)- Selected for actual detailed study • 210MW units are slowly getting obsolete. • Many plants have 500MW units, which are facing problems due to blending

- 14. Various Problems Mentioned at EEMG Workshop PLANT PROBLEMS FACED TANDA Part load, Steam pressure, Unburnt carbon. VINDHYACHAL MW shortfall, Condenser vacuum, High FEGT, Clinkering, Pressure fluctuations. KORBA Clinkering, Unburned carbon. BARH Vacuum loss, High make-up water requirement. SIMADHARI Air ingress problem. KEHALGAON High APC. UNCHAHAAR High APC, Cooling tower performance, Slagging at full load. SIPAT Safety valve problem, Cooling tower performance. FARAKHHA Clinkering problem, BFP performance. MOUDA Cooling tower performance, Condenser loss, APH performance. RAMAGUNDAM Unburnt carbon.

- 15. Geometrical Modelling Done till date in this project - in ANSYS-ICEM ICEM MODEL : UNCHAHAAR UNIT-1 Furnace Dimensions: D X W = 10.592m X 13.868m Boiler Height: 43.129m

- 16. ICEM MODEL : VINDHYACHAL UNIT-7 Geometrical Modelling Done in ANSYS-ICEM Furnace Dimensions: D X W = 15.797m X 19.177m Boiler Height: 62.313m

- 17. The Modelling Process in ANSYS-ICEM • Need to divide the boiler into number of small volumes (grid/mesh generation). • Smaller the unit volume size more the accuracy of predicted results, but require more computation time. • Approximately 1 million computational cells are required for simulation of a typical 500MW plant.

- 18. The Next Process – Analysis in ANSYS-FLUENT • FVM (Finite Volume Method) is used to calculate the physical properties at each point in space. • Physical processes such as coal combustion, radiation exchange, volatile release etc. are modelled using various mathematical models. • Boundary conditions such as fuel flow rate, pressure and temperature are put at all the inlets and outlets. • Grid independence is ensured.

- 19. TYPICAL EXPECTED RESULTS (Influence of Coal Blends on Temperature Distribution)

- 20. TYPICAL EXPECTED RESULTS (Influence of Coal Blends on Temperature Distribution)

- 21. TYPICAL EXPECTED RESULTS (Flow Distribution)

- 22. TYPICAL EXPECTED RESULTS (Coal Particles’ Tracking)

- 23. TYPICAL EXPECTED RESULTS (Influence of Burner Tilt on Temperature)

- 24. Project Timeline - Gantt Chart FEBRUARY 16 MARCH 16 APRIL 16 MAY 16 JUNE 16 W1 W2 W3 W4 W1 W2 W3 W4 W1 W2 W3 W4 W1 W2 W3 W4 W1 W2 W3 W4 ICEM Modelling and Coarse Meshing Vindhyachal Visit and Site Data Collection Fine Meshing of the Model Second Presentation on Project Progress General Validation of Model with Actual Site Results Report Writing and Final Presentation Implementation of Any Suggestions/ Trail

- 25. References 1. Modelling of a wall fired furnace for different operating conditions using FLUENT (2006) – VUTHALURU 2. Modeling of thermal characteristics for a furnace of a 500 MW boiler fired with high-ash coal (2001) – KOUPRIANOV 3. Modeling of a Coal-Fired Natural Circulation Boiler (2007) – BHAMBARE 4. Three-dimensional furnace computer modelling-BOYD 5. Modelling and prediction of NOx emission in a coal-fired power generation plant-LI 6. Modeling-of-a-front-wall-fired-utility-boiler-for-different-operating-conditions (2001)- XU 7. A-computational-fluid-dynamics-based-study-of-the-combustion-characteristics-of-coal-blends-in-pulverised-coal-fired- furnace_2004_Fuel-SHENG 8. Boilers and Burners-Design and Theory-Prabir_Basu 9. Computational Modeling of Pulverized Coal Fired Boilers- RANADE 10. 3D CFD modelling of 500MW tangentially fired tower type boiler - PRABODH 2002 11. CFD Modeling of Vindhyachal Stage II 500MWe Boiler- SWADHIN 2009 12. Effect of heating on char structure and fragmentation of high ash indian coal- KARMAKAR 2009 13. 3D CFD modelling of NOX and temperature imbalance in 500MW boiler-JENA 2007

- 26. Thank You