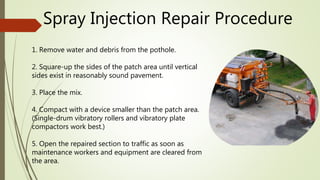

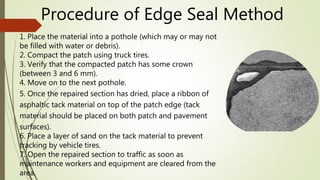

1) The document discusses different methods for repairing potholes in bituminous roads, including throw and roll, spray injection, and edge seal repairs.

2) It analyzes the formation of potholes, effects of potholes, and advantages and disadvantages of various repair techniques.

3) Spray injection and edge seal repairs provide more durable repairs compared to the basic throw and roll method, but require more equipment and time. Proper repair selection and technique can increase longevity and safety of roads.