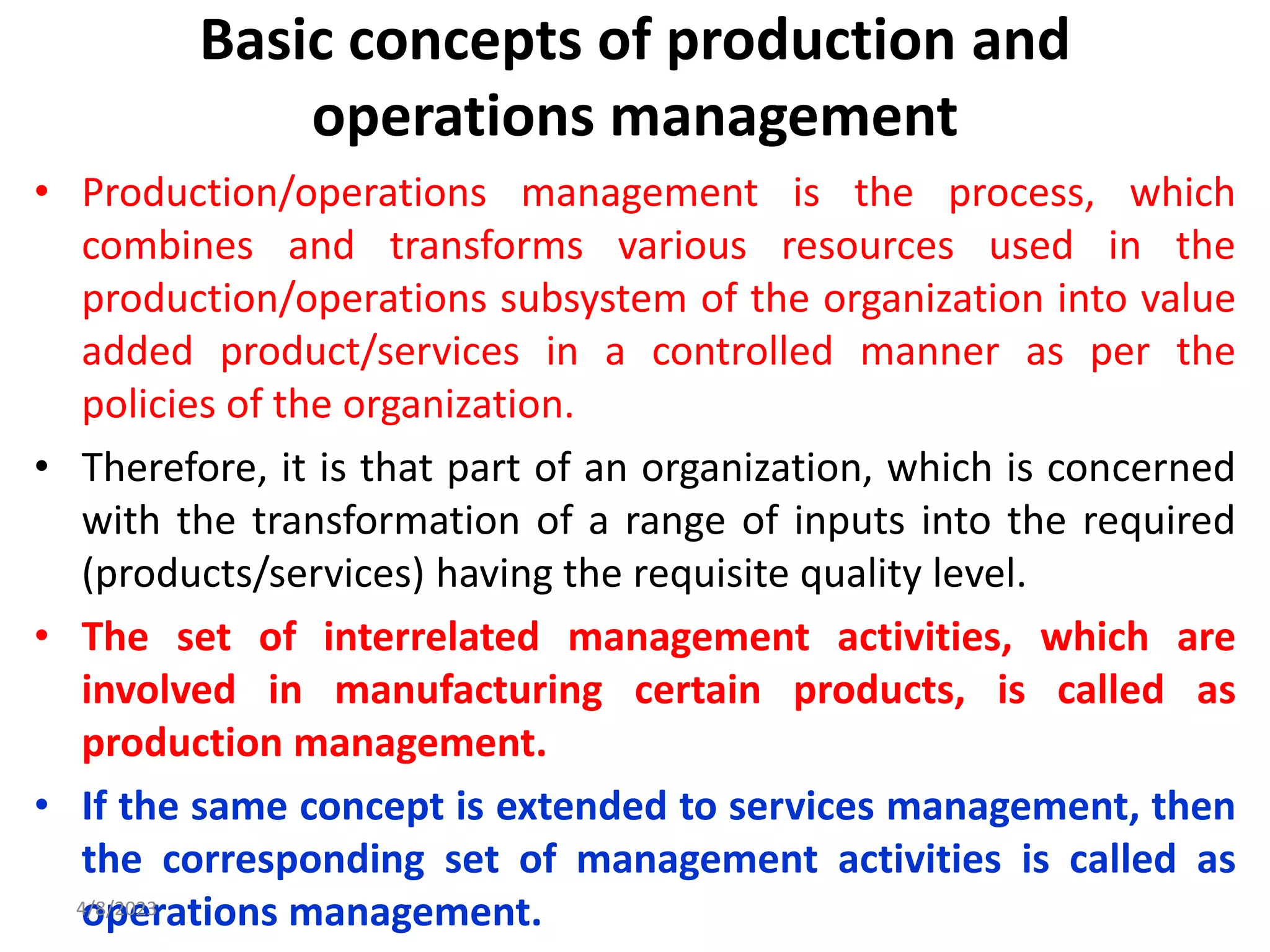

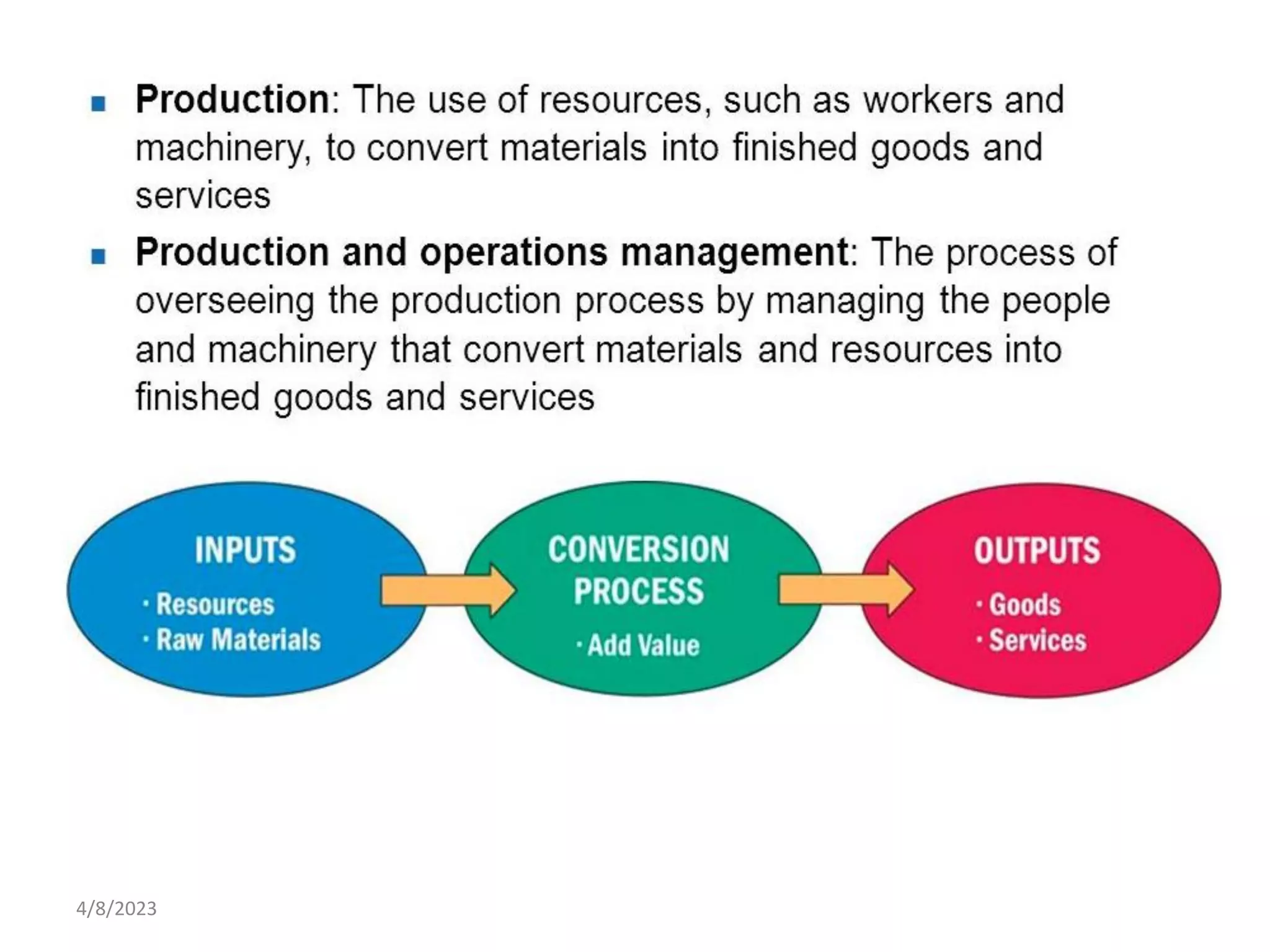

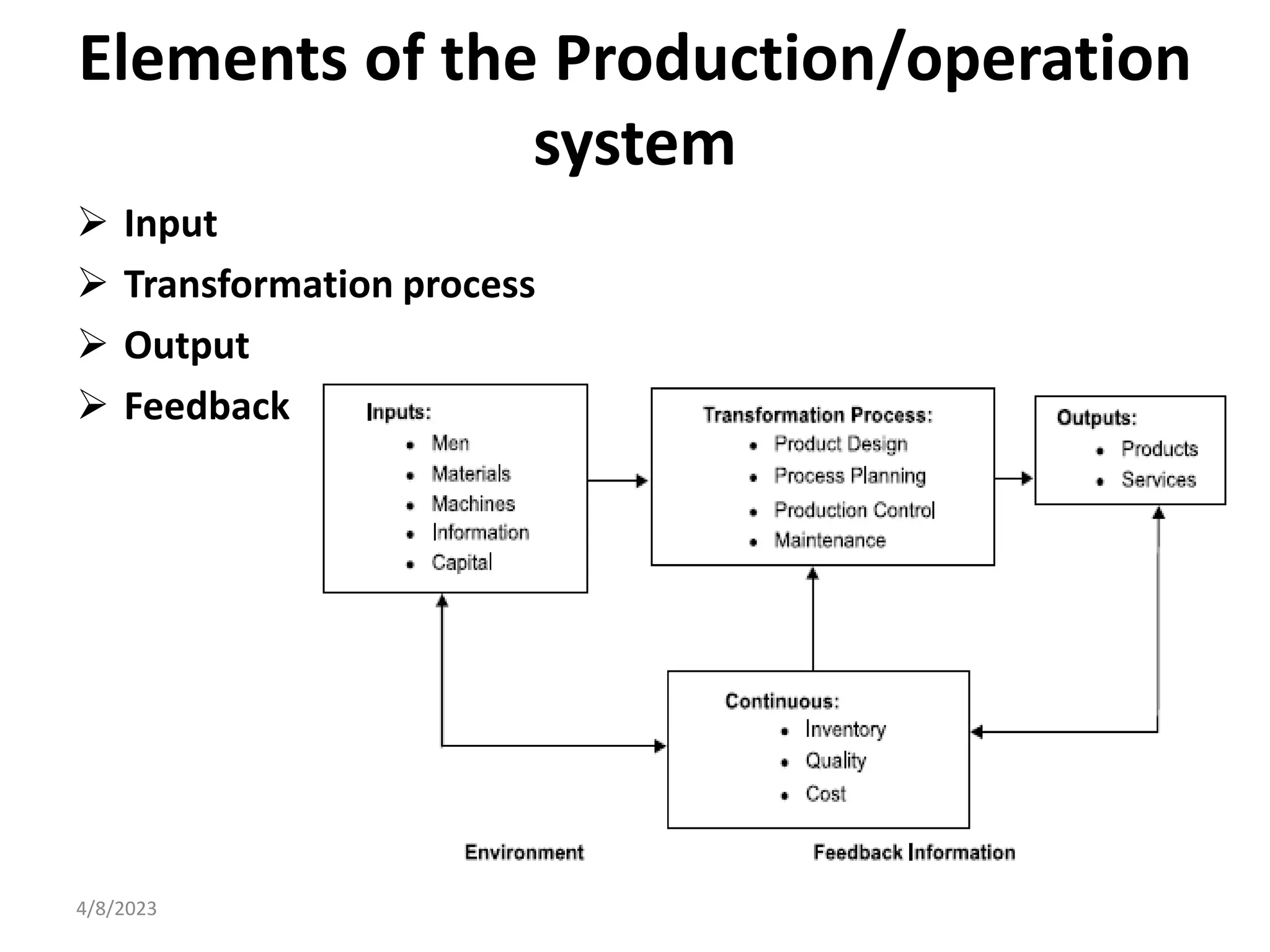

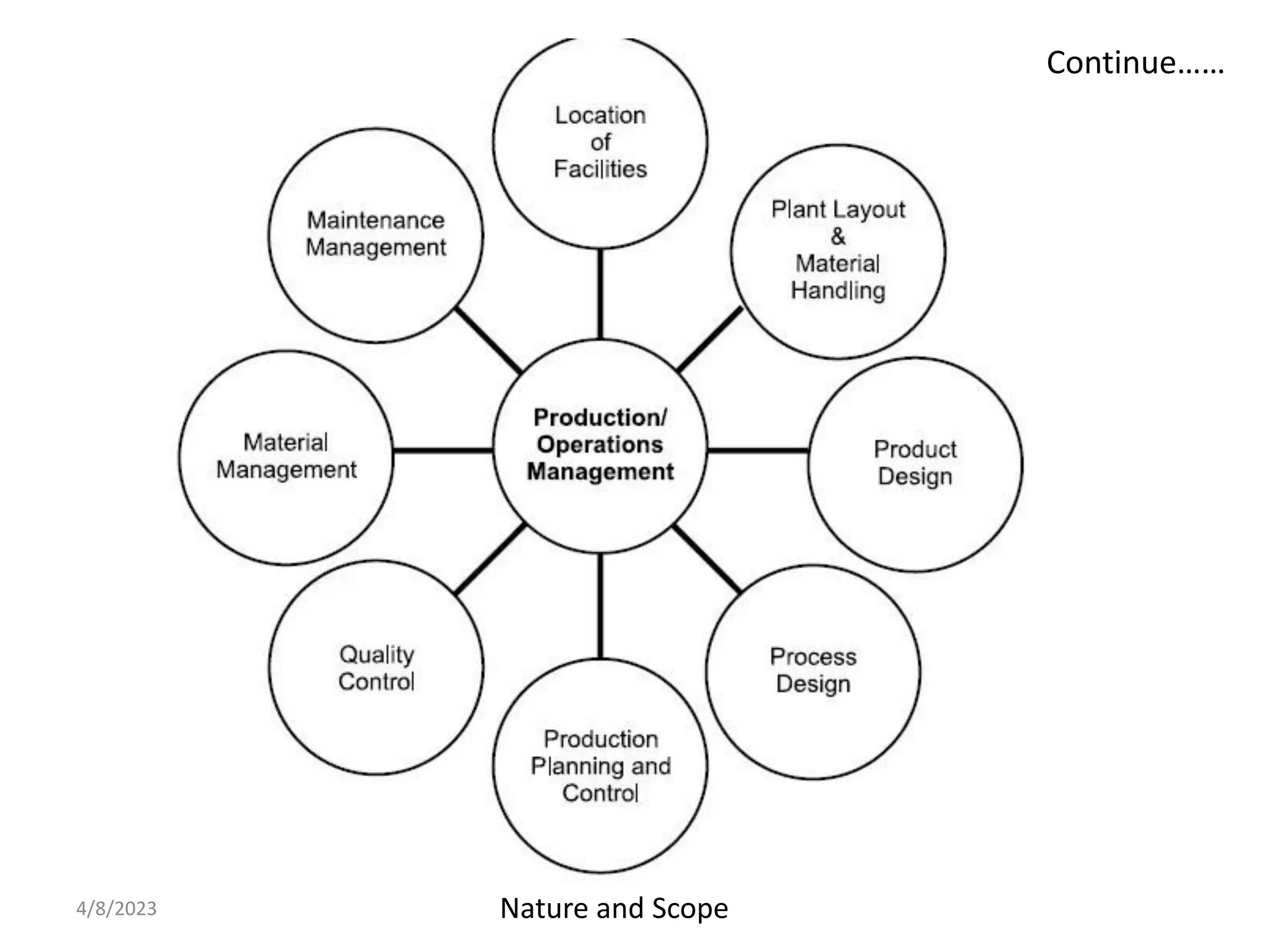

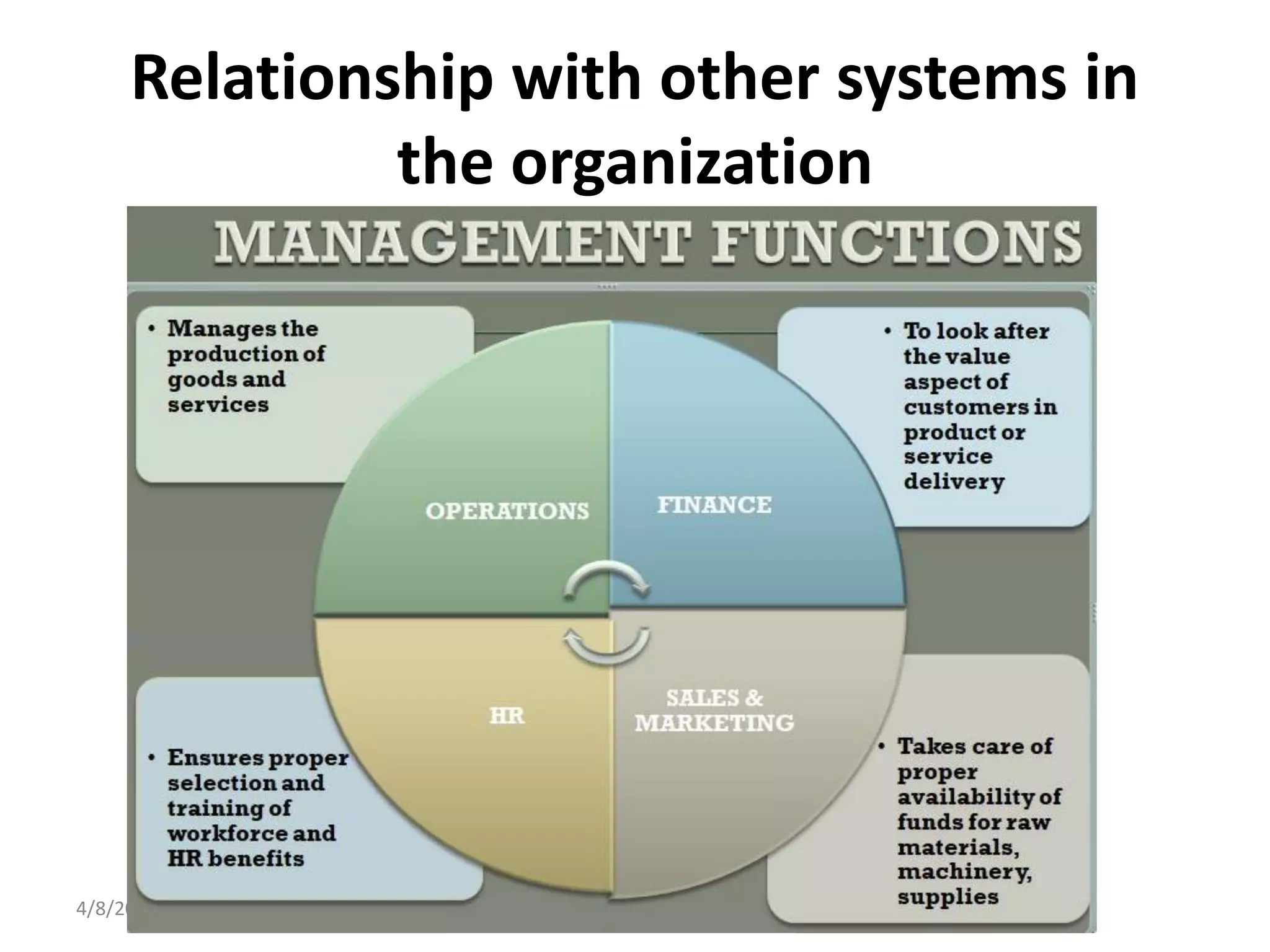

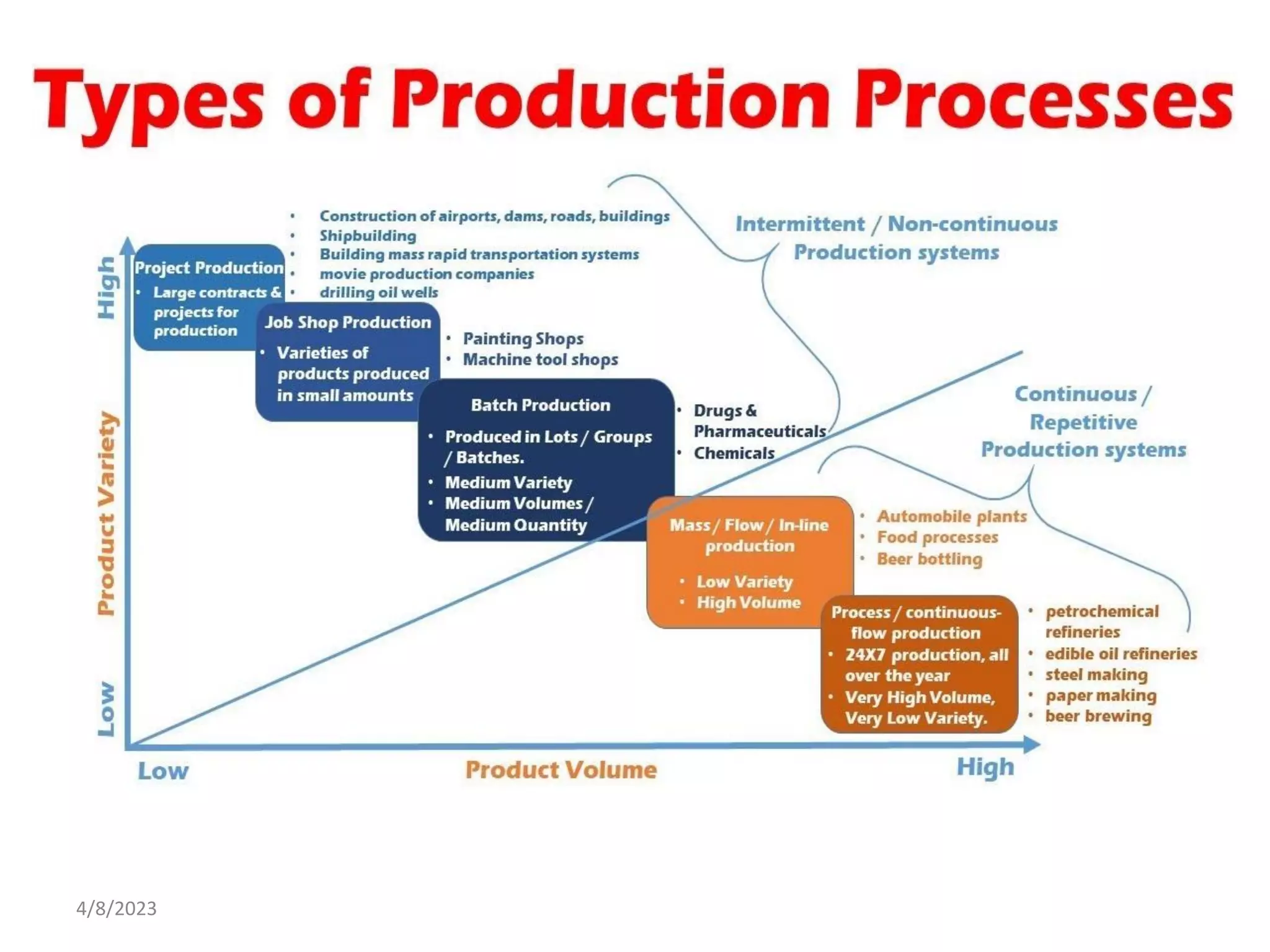

This document provides an overview of production and operations management. It begins by defining key terms like production, operations, and production/operations management. It then discusses the objectives and nature/scope of production/operations management, including the relationships with other systems and factors that affect it. The document also outlines some basic concepts like the elements of a production/operations system and a general model for managing operations. It provides details on planning, organizing, and controlling as the main management functions. Finally, it discusses internal factors that can affect production management.