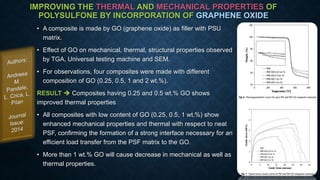

Polysulfone is a thermoplastic polymer developed for use above 149°C. It is synthesized via condensation polymerization of bisphenol A and 4,4'-dichlorodiphenyl sulfone. Grades include unfilled polysulfone as well as glass-filled and carbon-filled varieties. Polysulfone has good tensile strength, elongation, density, and chemical resistance, making it suitable for applications like medical equipment, plumbing fittings, and water treatment membranes. Research shows adding small amounts of graphene oxide as a filler can improve polysulfone's thermal and mechanical properties by strengthening the polymer-filler interface.