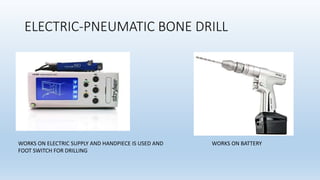

This document describes an electric-pneumatic bone drill. It has a trigger switch that activates an electric motor, which drives a rotating chuck that can hold various accessories for boring holes or driving screws. A bone drill is used in surgery to create holes in bones for inserting nails, screws, or other implants. It works using both electric power and a handpiece operated via foot switch. Advantages include adjustable handpiece speeds and a lighter, shorter handpiece that remains cool. Disadvantages can include accidentally drilling too deep and heat buildup. Safety precautions when using it include wearing protective eyewear and lubricating to prevent overheating.