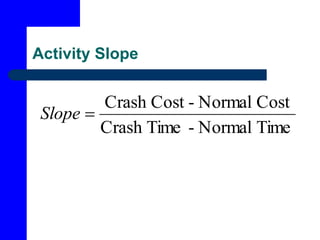

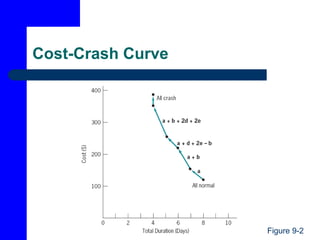

Here are the steps to solve this problem:

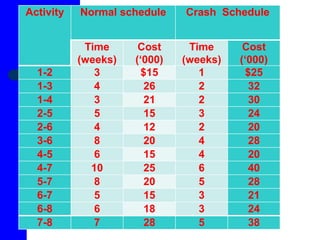

1. Find the all-normal schedule: Total time = max(3, 4, 3, 5, 4, 8, 6, 10, 8, 5, 6, 7) = 10 weeks. Total cost = sum of normal costs = $15 + $26 + $21 + $15 + $12 + $20 + $15 + $25 + $20 + $15 + $18 + $28 = $255k

2. Find the all-crash schedule: Total time = max(1, 2, 2, 3, 2, 4, 4, 6, 5, 3, 3, 5) = 6 weeks. Total cost = sum of crash