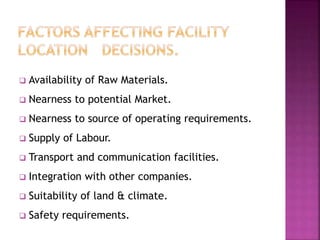

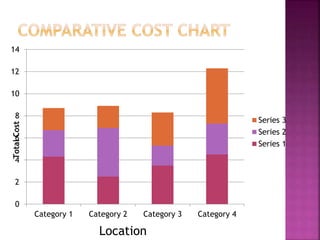

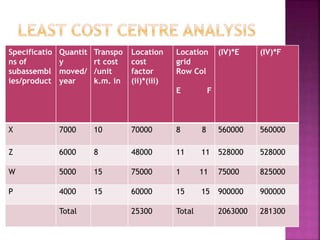

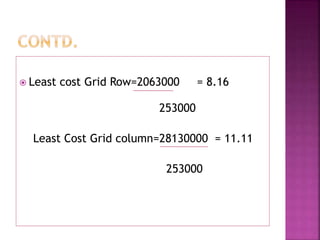

The document discusses facility location analysis. It defines facilities as buildings where people, materials, and machines come together for a stated purpose, such as manufacturing or service provision. Proper facility management is important to achieve goals while satisfying objectives. Location analysis determines the best geographic site for a firm's operations based on factors like costs, market access, and plant design impacts. Quantitative techniques in location analysis include cost-benefit analysis and break-even analysis to evaluate locations and minimize total costs and maximize profits. Qualitative factors considered are availability of resources, climate suitability, and integration with other companies. Multiple location analysis methods are outlined including weighted factor rating.