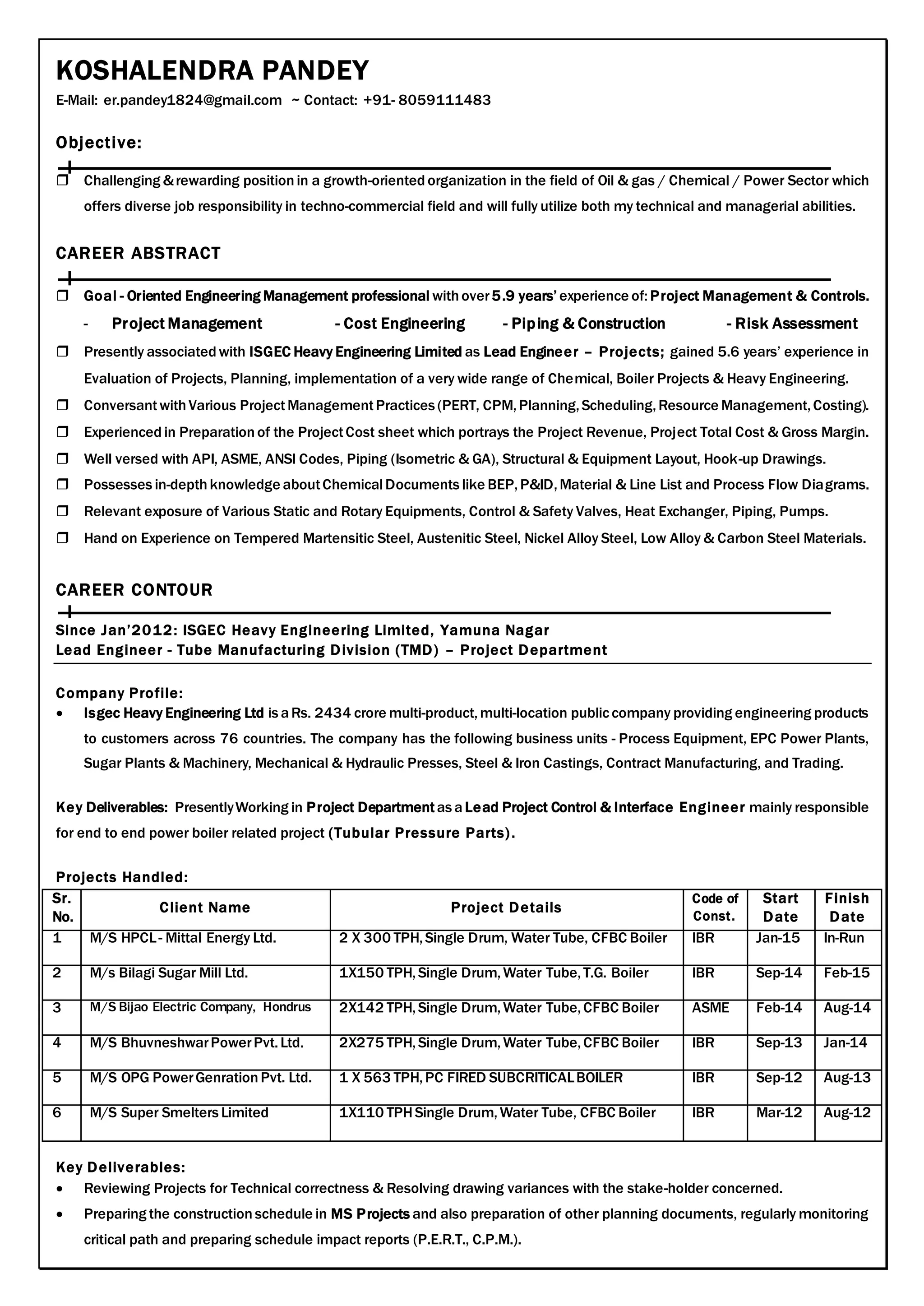

Koshalendra Pandey is an experienced engineering professional seeking a challenging position utilizing both technical and managerial skills. He has over 5.9 years of experience in project management, cost engineering, piping, and construction. Currently he is a Lead Engineer at ISGEC Heavy Engineering Limited, where he has worked for 5.6 years managing various chemical, boiler, and engineering projects. Previously he worked as a Senior Executive managing chemical process plant projects at SRF Limited. He holds an M.E. in Mechanical Engineering from BITS Pilani and a B.E. in Mechanical Engineering.