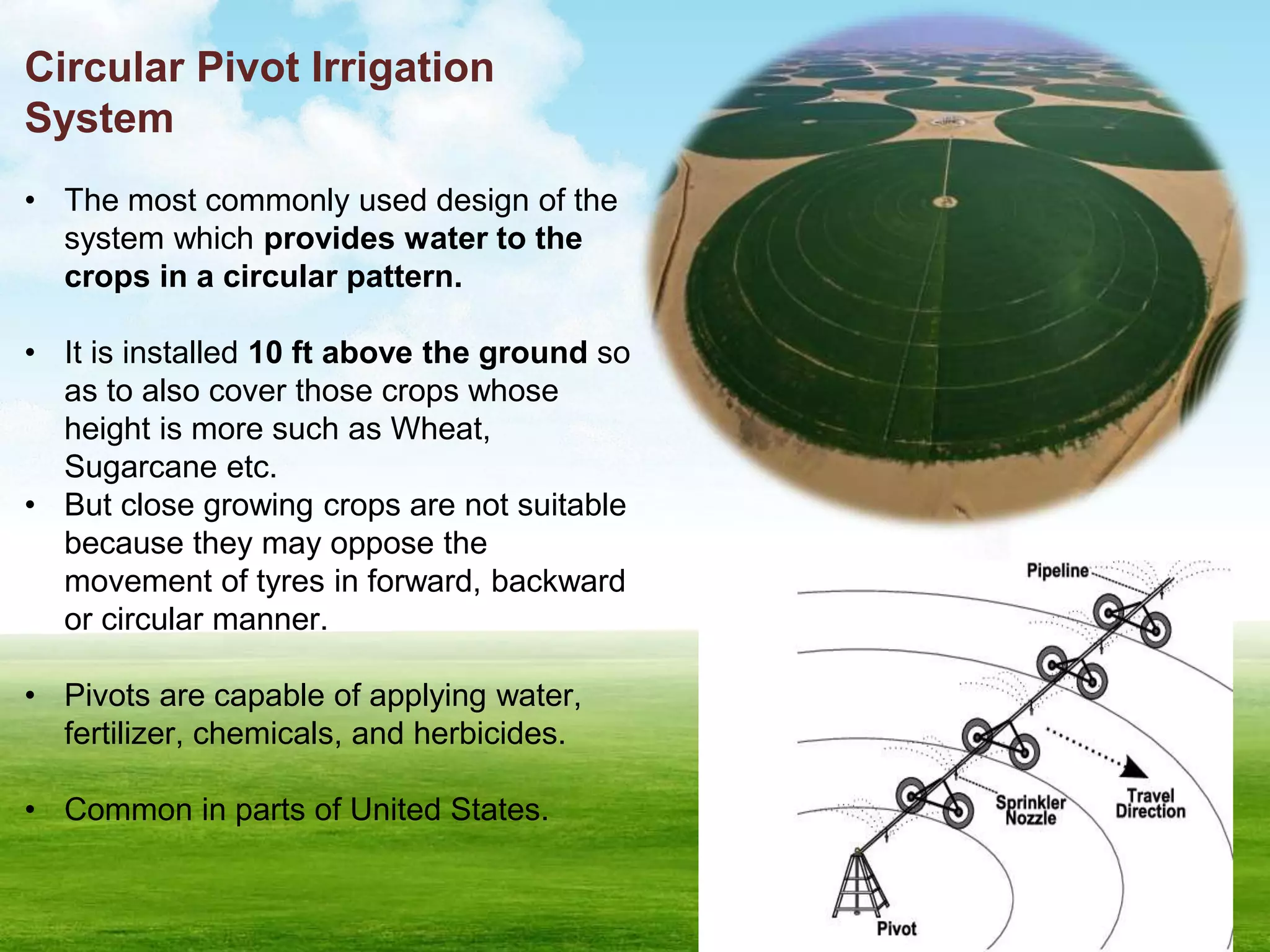

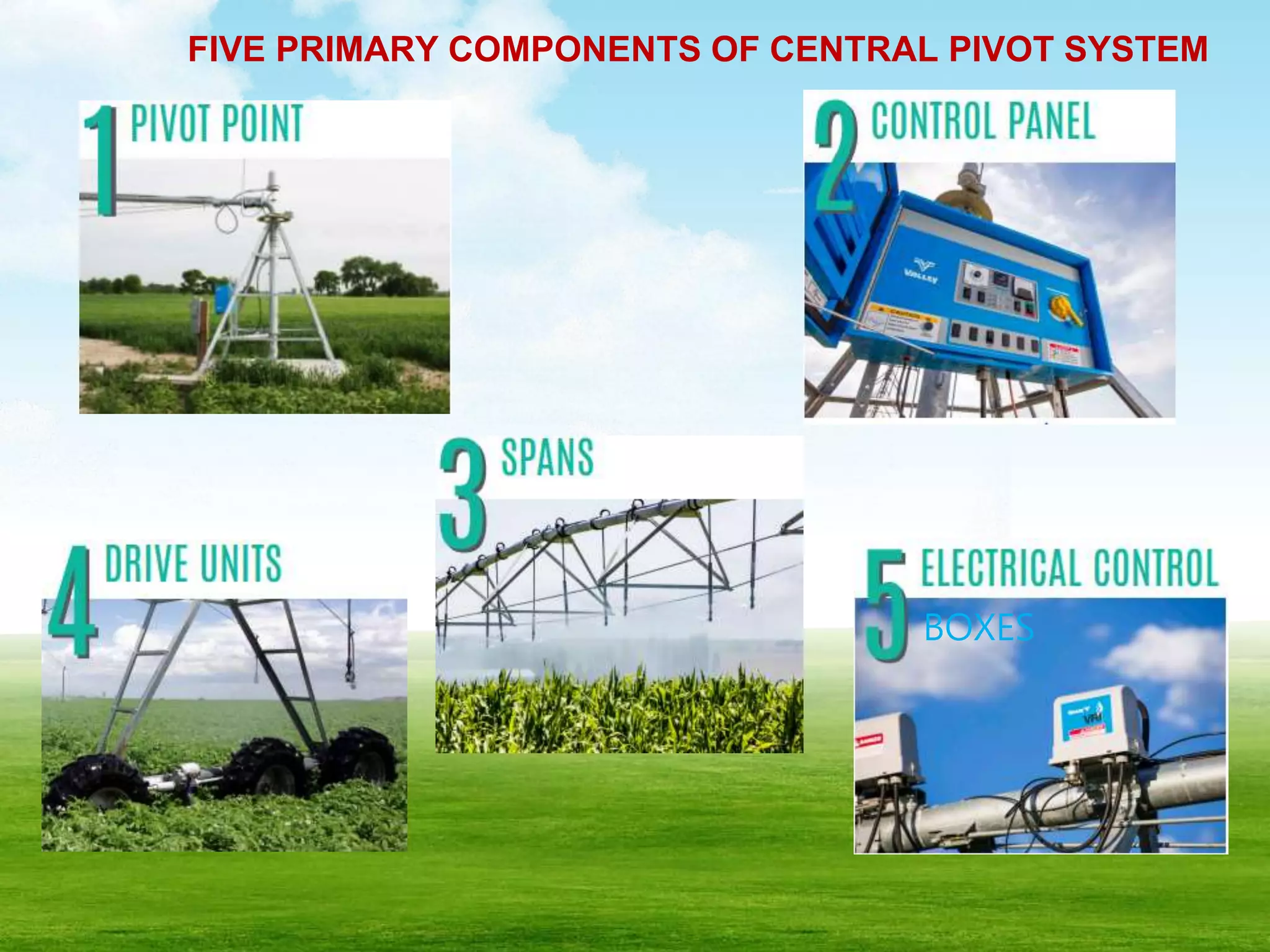

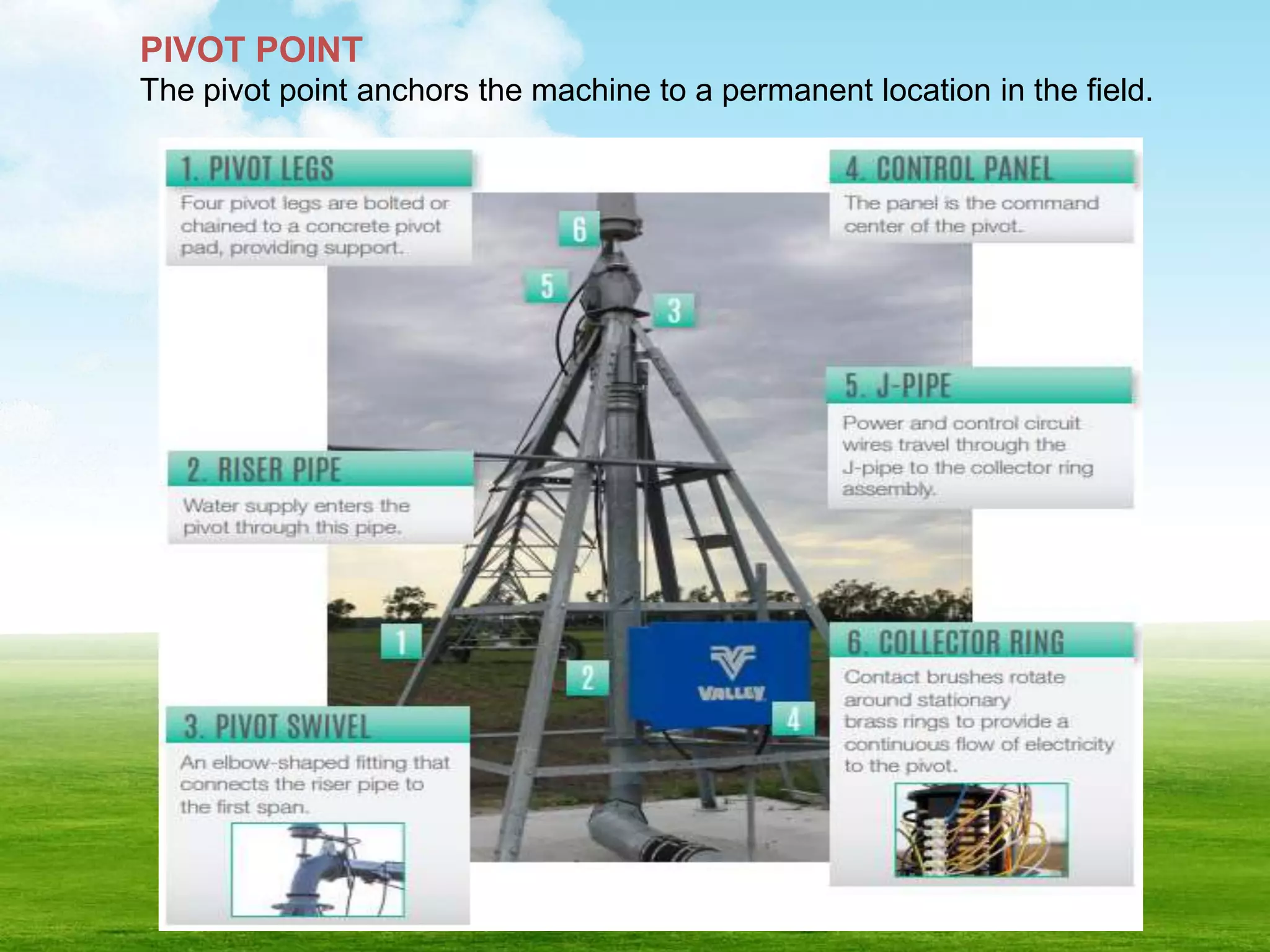

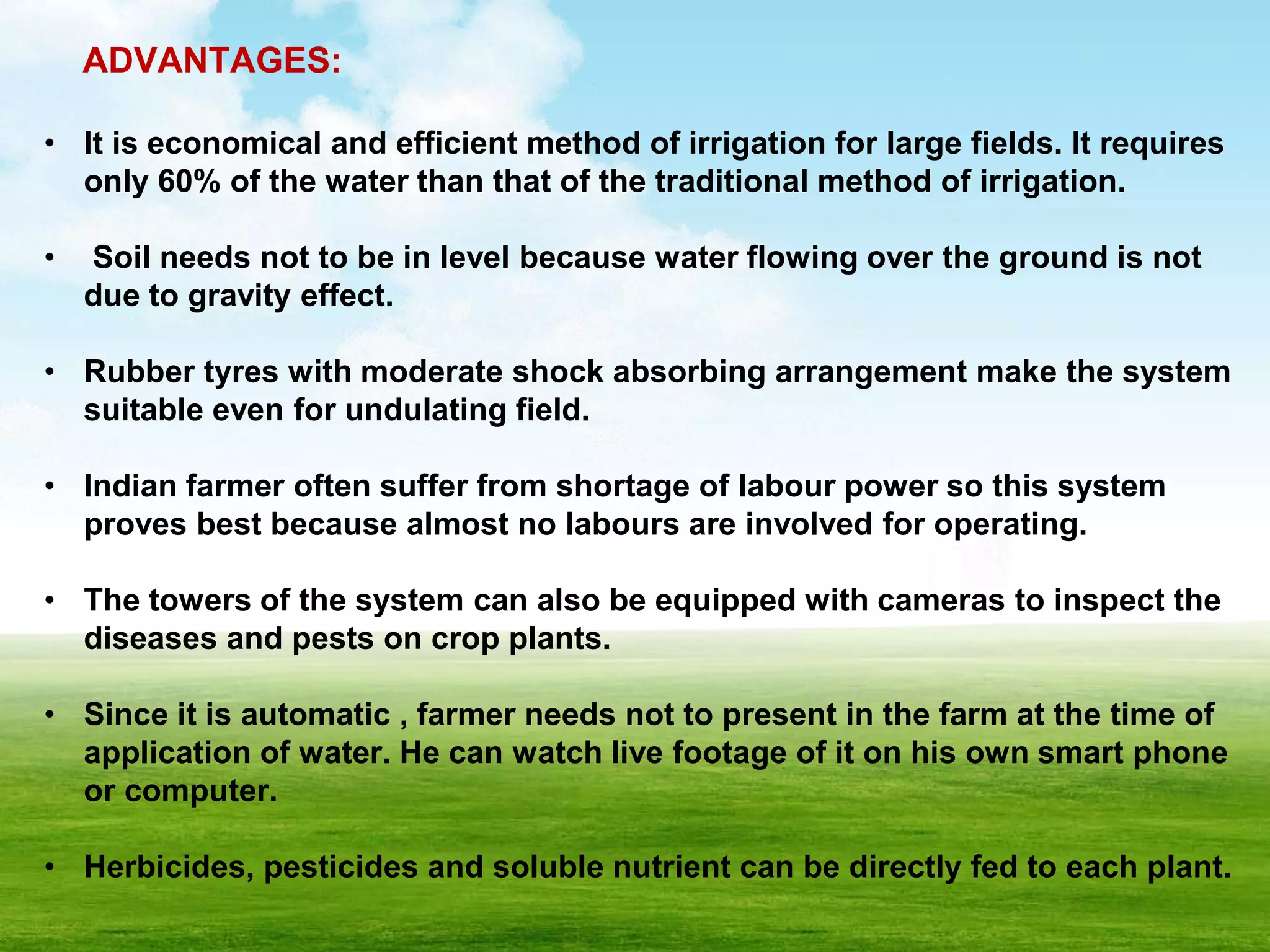

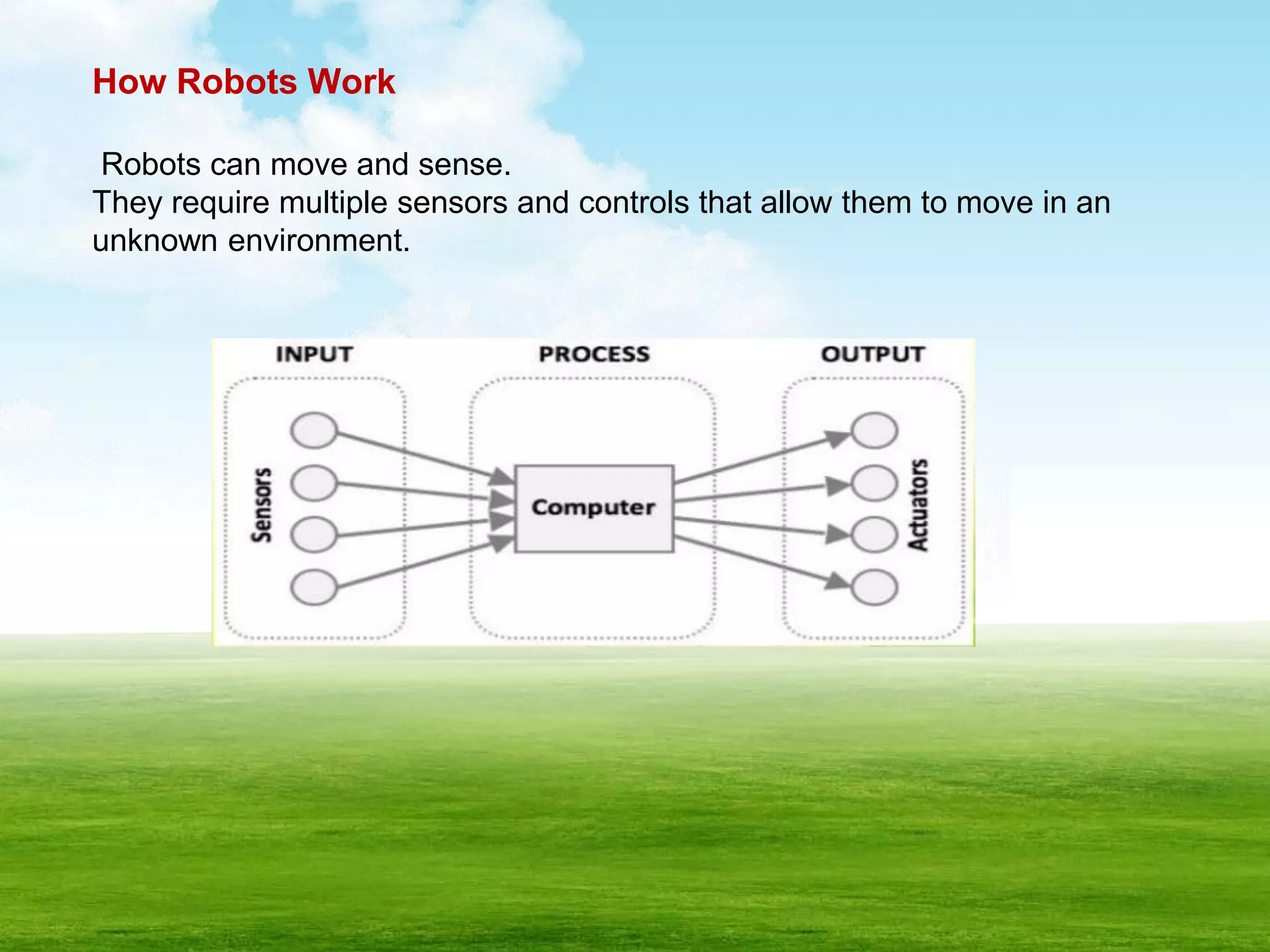

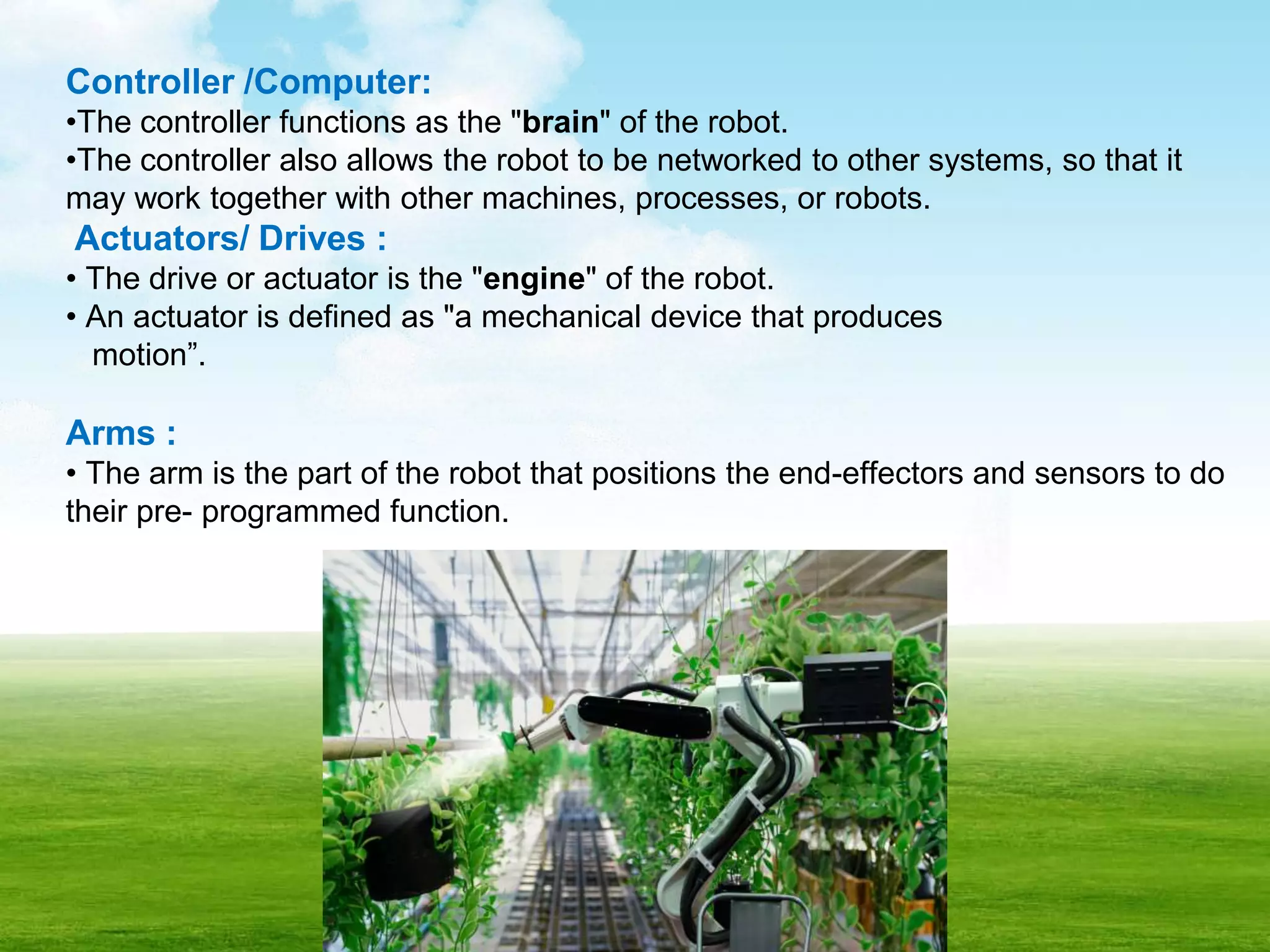

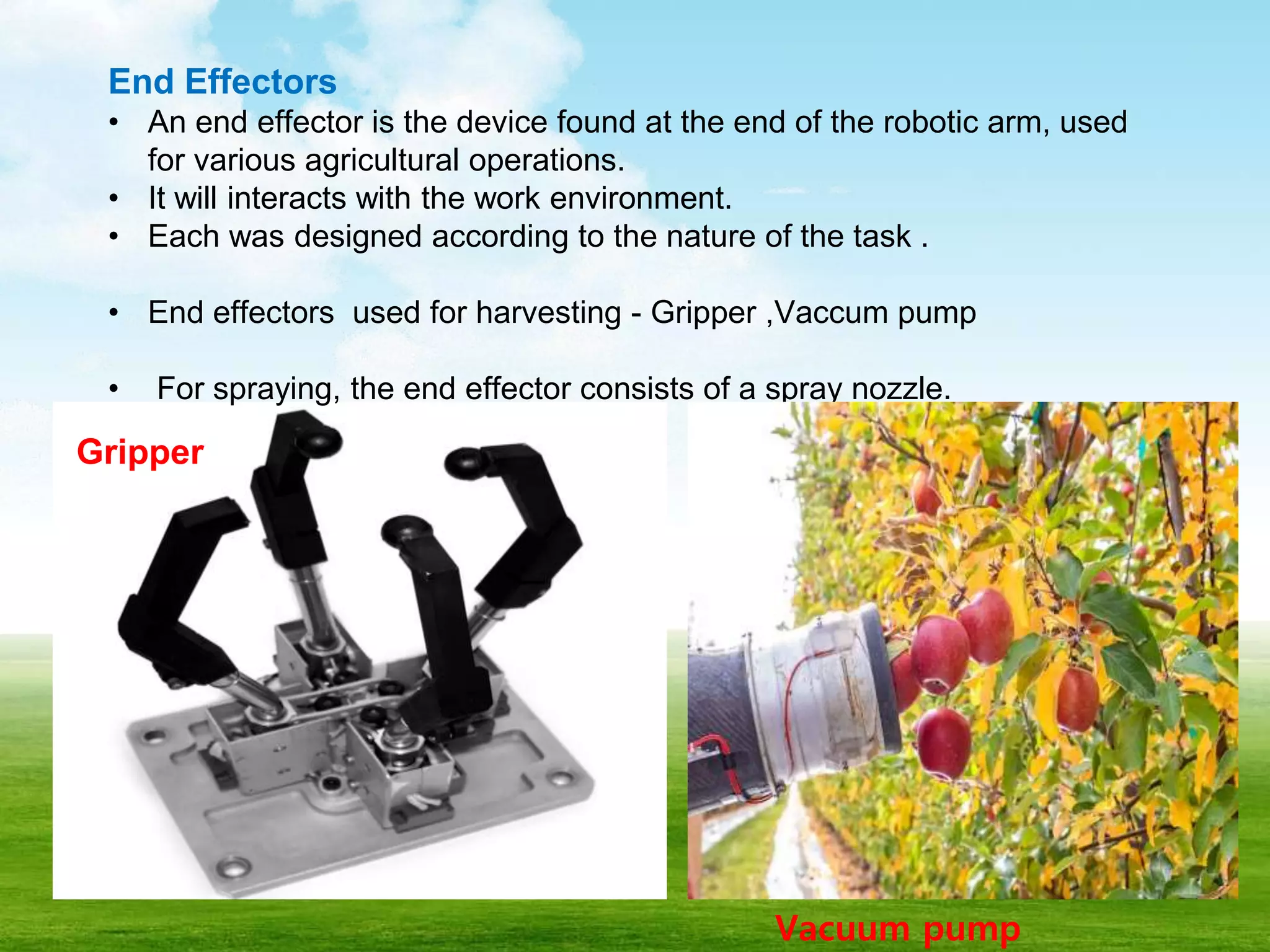

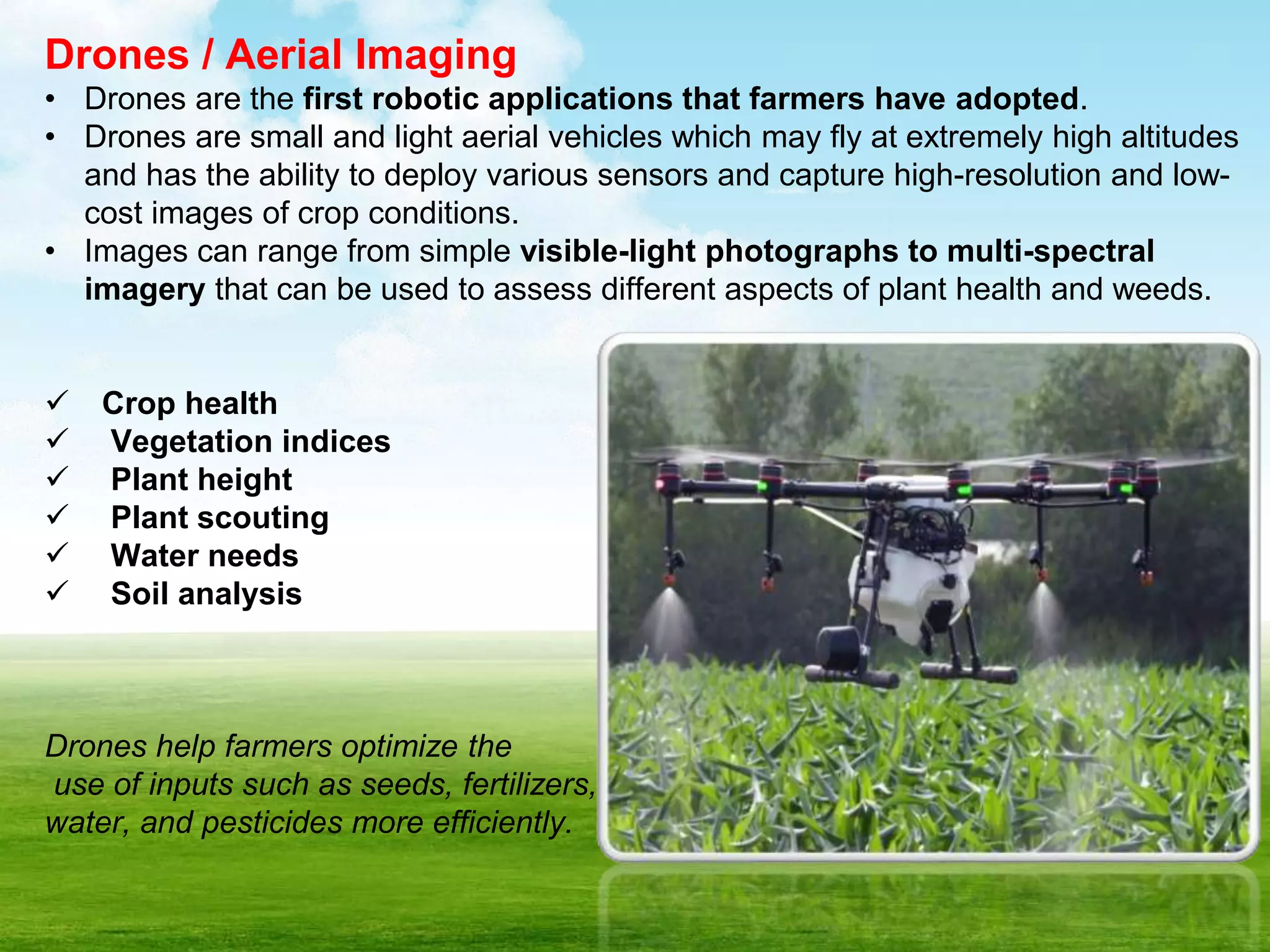

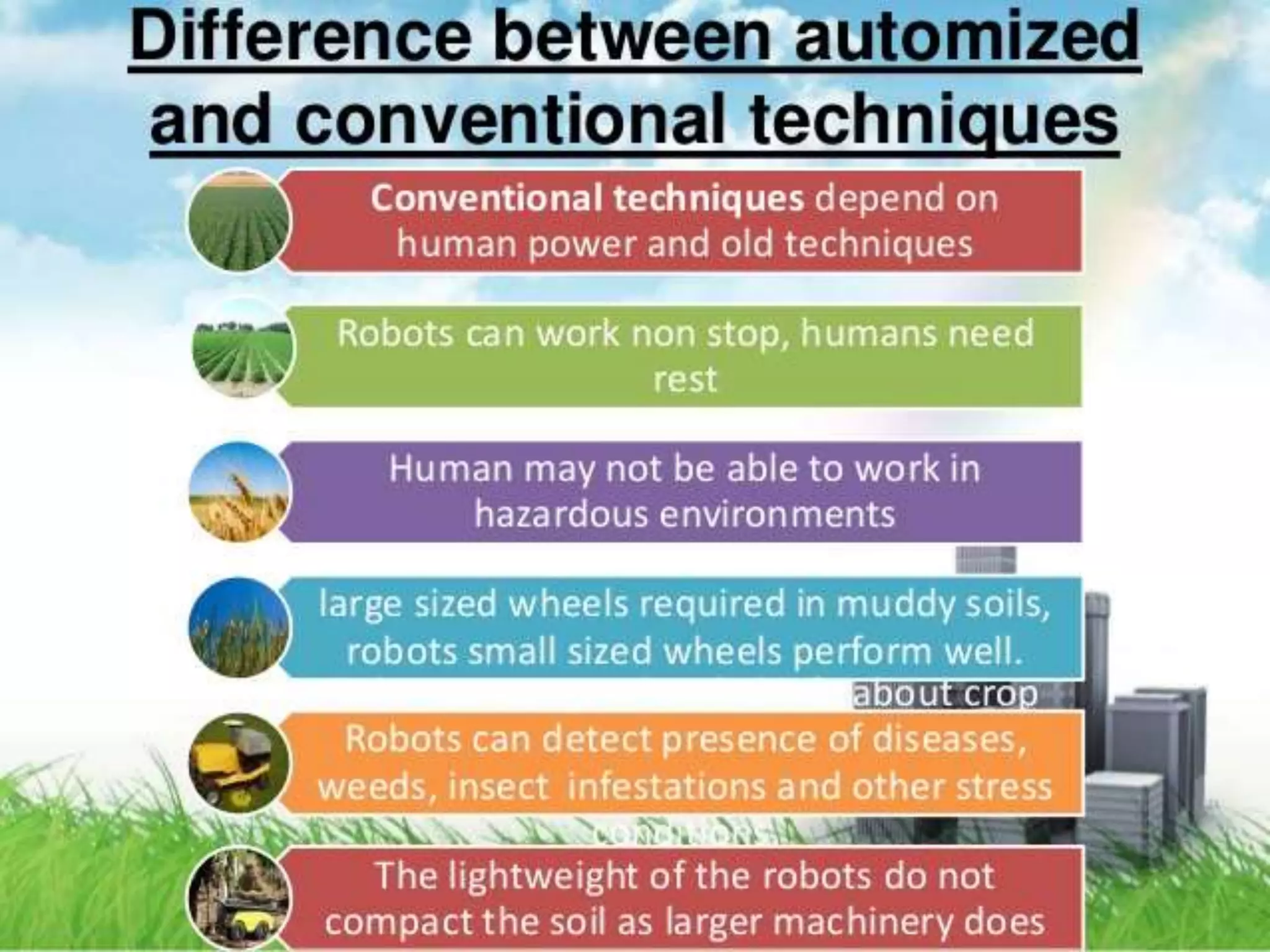

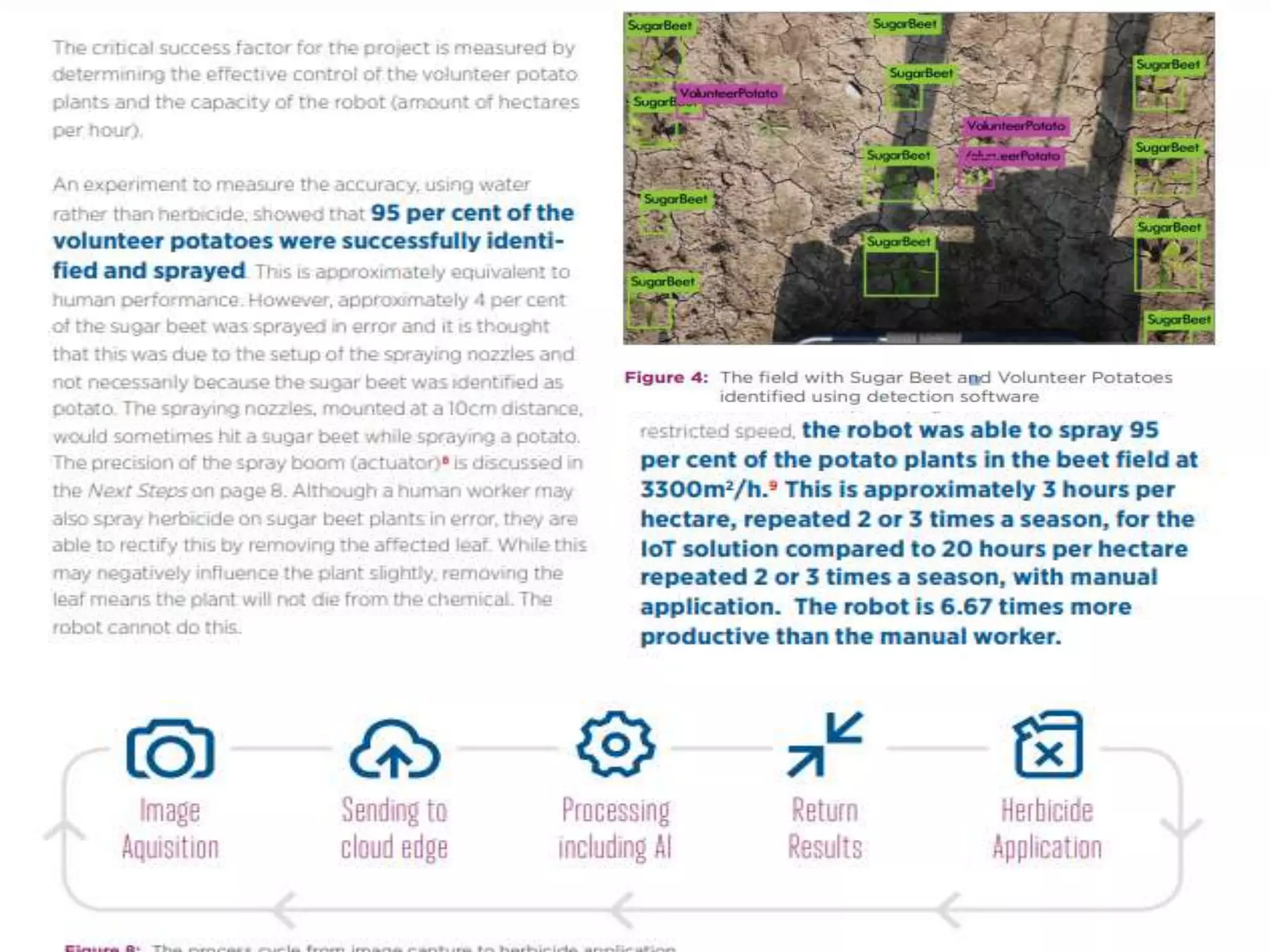

Centre pivot irrigation systems use overhead sprinklers mounted on a series of pipes that rotate around a central pivot point, watering circular sections of crops. Key components include the pivot point, control panel, spans to carry water and sprinklers, and drive units with wheels. While initially costly, these systems provide efficient irrigation with less water than traditional methods and can cover uneven terrain. Robotic technologies are also being applied to agriculture through devices that can autonomously perform tasks like weeding, spraying, harvesting and monitoring crops under human supervision. Sensors, controllers, actuators and end effectors allow robots to navigate and interact with fields. Both centre pivots and agricultural robots have the potential to increase productivity and efficiency while reducing labor needs.

![REFERENCES

• Centre Pivot Irrigation-A Modern Method of Irrigation in Indian

Perspective, Volume 2, Issue 12, December 2016,IJARSMT.

• James, L. G . 1982. Modeling the performance of center pivot

irrigation systems operating on variable topography.

TRANSACTIONS of the ASAE 25(1):143-149.

• Investing in centre pivot and lateral move systems | Centre pivot

and lateral move systems | Irrigation | Water | Farm management |

Agriculture Victoria.

• PIVOTBASICS ,Wilcox, J. C . and G . E. Sw ailes. 1947,Scientific

Agriculture 27:565-583.

• Agricultural robotics and automated equipment for sustainable

crop production ,By Santiago Santos Valle, Agricultural

Mechanization Specialist, FAO Josef Kienzle, Agricultural Engineer,

FAO NOVEMBER 2020 Food and Agriculture Organization of the

United Nations Rome, 2020

• Agrobot. 2020. Agrobot [online]. Huelva, Spain. [Cited 4 August

2020]. https://www.agrobot.com/

• Bechar, A. & Vigneault, C. 2016. Agricultural robots for field

operations: Concepts and components. Biosystems Engineering,

149: 94–111](https://image.slidesharecdn.com/roboticsinagriculture-210919142956/75/Pivot-System-and-Robotics-in-Agriculture-39-2048.jpg)