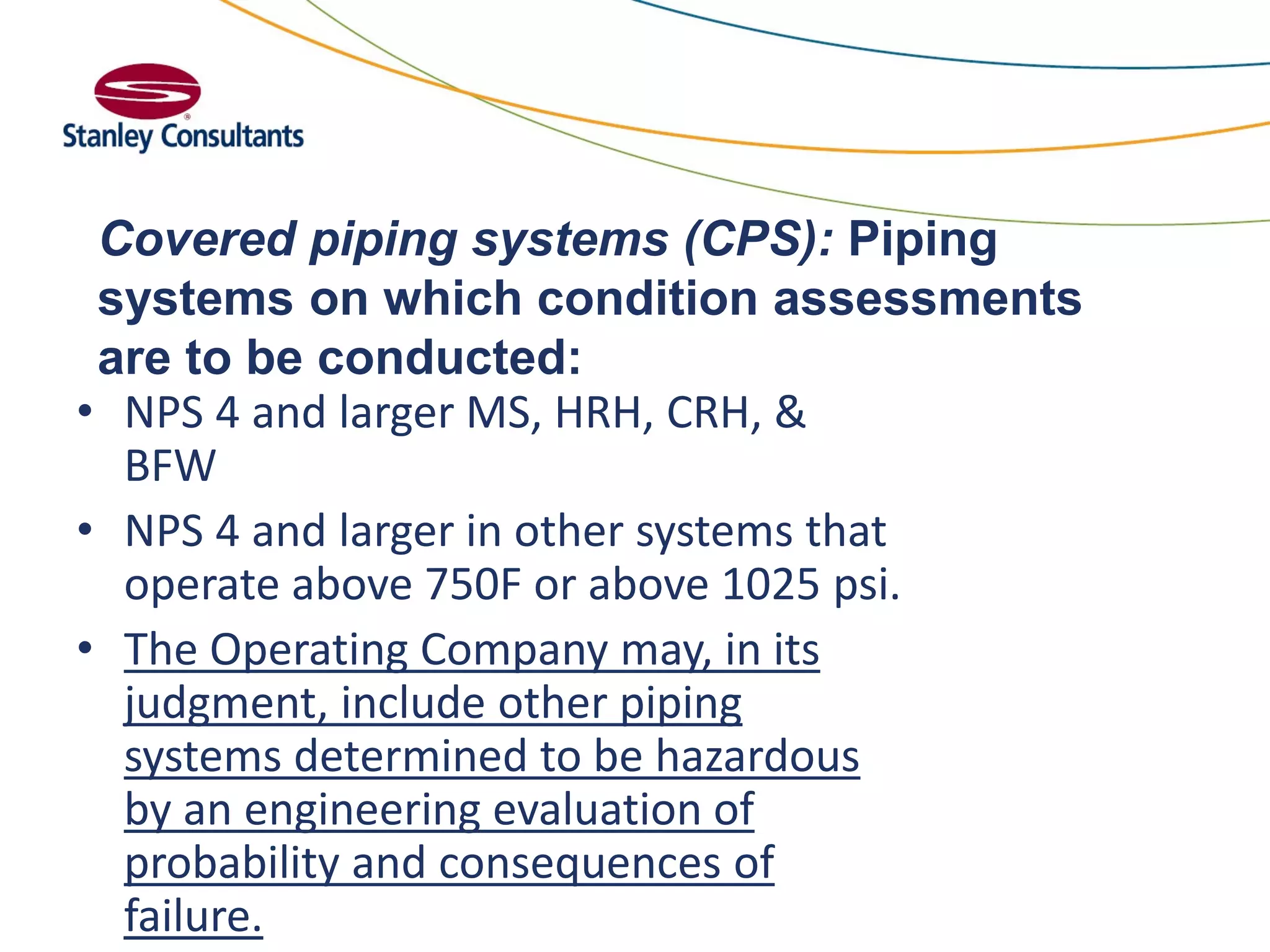

This document summarizes a presentation about ASME B31.1 requirements for operation and maintenance (O&M) of piping systems from a code perspective. It discusses the history and organization of O&M requirements in the B31.1 code, including the addition of Chapter VII in 2007. It outlines the goals of O&M, including managing piping safety throughout its lifespan and conducting condition assessments. Examples of common pressure pipe failures that prompted improved O&M are also summarized, such as a desuperheater piping failure caused by thermal stresses known as the "banana effect".