Pipe laying barge

•Download as PPT, PDF•

1 like•153 views

Upgrade to current technology, minimize hardware cost, customize control system for application needs.

Report

Share

Report

Share

Recommended

Extrusion thermoforming line

The project involved retrofitting an existing plastic extrusion line with an updated control system. A vendor supplied new controls, interfaces, and PLCs to replace 15 existing drives and programmed the PLC. Installation and wiring was completed in 5 days, 2 days ahead of schedule. The line includes 4 extruder/melt pump combinations and controls casting, pull, and thermoforming processes. Operators use 5 touch screens to monitor and control the line. The retrofit allows melt pumps and extruders to restart while the line is running, improving operations.

Understanding Integrated Motion Control Systems

Say you have a simple task you'd like to automate, but you're not sure how. How do you find or design the best possible automation solution that will meet your requirements? This SlideShare will help you understand the components that make up integrated motion control systems, and how complete solutions are designed for specific tasks.

Motion Control Theory. servomotor

ommon motion systems use three types of control methods. They are position control, velocity control and torque control.

The majority of Newport’s motion systems use position control. This type of control moves the load from one known fixed position to another known fixed position. Feedback, or closed-loop positioning, is important for precise positioning.

Velocity control moves the load continuously for a certain time interval or moves the load from one place to another at a prescribed velocity. Newport’s systems use both encoder and tachometer feedback to regulate velocity.

Torque control measures the current applied to a motor with a known torque coefficient in order to develop a known constant torque. Newport’s motion systems do not employ this method of control.

Improving Accuracy With Servomotors And High Speed Network

Servo motors are important for improving accuracy in industrial machines. Servo motors use encoders with high resolution of up to 24 bits for precise positioning. Features of servo drives like vibration suppression and motor ripple compensation help improve machine accuracy. Using high-speed Ethernet networks of 125 microseconds between controllers and servo drives also enhances accuracy when controlling servo motion. A variety of servo motor types exist, including rotary, direct drive, and linear motors, which are chosen based on the machine's needs. Achieving high accuracy requires consideration of factors like motion control, feedback encoders, and compensation for mechanical properties.

Chapter 1

The document discusses motion control systems and their applications. It covers the components of a motion control system including the application software, motion controller, amplifiers/drives, motors, mechanical elements, feedback devices and motion I/O. It also discusses common motion control functions like sequencing, speed control and point-to-point control. Finally, it discusses motion control variables like position, angle and speed and provides examples of motion profiles and multi-axis motion.

Mitsubishi ac servos linear servo lm series dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.org

Hoist vfd control

This document discusses control requirements and component choices for hoists with and without mechanical load brakes. For hoists without load brakes, it recommends using a closed-loop flux vector drive with encoder feedback and dynamic braking to dissipate regenerative energy. It then highlights the features of PEI's Multi-Vector drive designed specifically for hoist applications, including built-in regeneration, easy setup, high reliability, and safety features.

Mitsubishi inverter 1412789969 fr-e700_catalog_dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.vn

Recommended

Extrusion thermoforming line

The project involved retrofitting an existing plastic extrusion line with an updated control system. A vendor supplied new controls, interfaces, and PLCs to replace 15 existing drives and programmed the PLC. Installation and wiring was completed in 5 days, 2 days ahead of schedule. The line includes 4 extruder/melt pump combinations and controls casting, pull, and thermoforming processes. Operators use 5 touch screens to monitor and control the line. The retrofit allows melt pumps and extruders to restart while the line is running, improving operations.

Understanding Integrated Motion Control Systems

Say you have a simple task you'd like to automate, but you're not sure how. How do you find or design the best possible automation solution that will meet your requirements? This SlideShare will help you understand the components that make up integrated motion control systems, and how complete solutions are designed for specific tasks.

Motion Control Theory. servomotor

ommon motion systems use three types of control methods. They are position control, velocity control and torque control.

The majority of Newport’s motion systems use position control. This type of control moves the load from one known fixed position to another known fixed position. Feedback, or closed-loop positioning, is important for precise positioning.

Velocity control moves the load continuously for a certain time interval or moves the load from one place to another at a prescribed velocity. Newport’s systems use both encoder and tachometer feedback to regulate velocity.

Torque control measures the current applied to a motor with a known torque coefficient in order to develop a known constant torque. Newport’s motion systems do not employ this method of control.

Improving Accuracy With Servomotors And High Speed Network

Servo motors are important for improving accuracy in industrial machines. Servo motors use encoders with high resolution of up to 24 bits for precise positioning. Features of servo drives like vibration suppression and motor ripple compensation help improve machine accuracy. Using high-speed Ethernet networks of 125 microseconds between controllers and servo drives also enhances accuracy when controlling servo motion. A variety of servo motor types exist, including rotary, direct drive, and linear motors, which are chosen based on the machine's needs. Achieving high accuracy requires consideration of factors like motion control, feedback encoders, and compensation for mechanical properties.

Chapter 1

The document discusses motion control systems and their applications. It covers the components of a motion control system including the application software, motion controller, amplifiers/drives, motors, mechanical elements, feedback devices and motion I/O. It also discusses common motion control functions like sequencing, speed control and point-to-point control. Finally, it discusses motion control variables like position, angle and speed and provides examples of motion profiles and multi-axis motion.

Mitsubishi ac servos linear servo lm series dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.org

Hoist vfd control

This document discusses control requirements and component choices for hoists with and without mechanical load brakes. For hoists without load brakes, it recommends using a closed-loop flux vector drive with encoder feedback and dynamic braking to dissipate regenerative energy. It then highlights the features of PEI's Multi-Vector drive designed specifically for hoist applications, including built-in regeneration, easy setup, high reliability, and safety features.

Mitsubishi inverter 1412789969 fr-e700_catalog_dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.vn

Servo motor and AVR Atmel Atmega 16

The document discusses how to configure timers on an Arduino to generate pulse-width modulated (PWM) signals for controlling servo motors. It explains that servo motors use PWM signals of varying pulse widths to control angular position precisely. It then provides code examples and explanations for setting up timer 1 on an Arduino in fast PWM mode at 50Hz to generate the necessary PWM signals, including setting the prescaler, waveform generation mode, and compare value. It also gives examples of PWM pulse widths needed to control a servo at different angles.

Mitsubishi inverter fr-e700 catalog-dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.vn

OneGear SMC 15kV Soft Starter

The document describes Rockwell Automation's OneGear medium voltage arc resistant soft starter for 10-15kV motors up to 11MW. It allows controlled acceleration and deceleration of motors to minimize wear while reducing energy consumption. Key features include arc flash protection, flexible control options, integral bypass, and easy replacement of components. Applications include pumps, chillers, compressors, and more. It provides intelligence, performance, flexibility, diagnostics and communications.

Mitsubishi inverter freqrol-a700 series dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.vn

Limitorque QX Electronic Actuator User Instructions

The Flowserve Limitorque QX quarter-turn smart electronic valve actuator continues the legacy of the industry’s state-of-the-art, non-intrusive, multi-turn MX actuator by including an absolute encoder for tracking position without the use of troublesome batteries. The QX design provides enhanced safety and reduced downtime through improved diagnostics, built-in self-test (BIST) features and LimiGard™ fault protection.

The QX design builds on more than 10 years of experience with proven Limitorque MX technology - the first generation double-sealed electronic valve actuator from Flowserve designed to provide control, ease of use and accuracy. The QX includes all the user-preferred features of the MX in a quarter-turn smart actuator package. It is the only non-intrusive, double-sealed quarter-turn actuator to display the Limitorque brand.

Thông số kỹ thuật bộ điều khiển tốc độ DKM catalogue speed control DKM

Thông số kỹ thuật bộ điều khiển tốc độ DKM catalogue speed control DKMCông ty cổ phần OKS | Tổng thầu thi công Nhà máy GMP, Tổng thầu thi công Nhà kho GSP

1. The document provides specifications for DKM speed control motors and controllers, including the FX1000A digital type system, DSK socket type system, and technical specifications.

2. It describes speed control methods, features of the FX1000A and DSK systems like easy connection and operation, and general technical specifications for controllers.

3. Tables provide motor line-up details, output capacities, frame sizes, power voltages, and connection diagrams for understanding specifications.Variable Frequency Drives

This document summarizes a presentation on variable frequency drives (VFDs). VFDs vary the speed of 3-phase AC motors by converting AC power to DC and then converting it back to variable voltage/frequency AC. They allow constant and variable torque motor loads to operate at variable speeds. Applications include pumps, fans, compressors. Selecting a VFD depends on the motor's current, kW rating, type of machine/application, and required functionality/controls. Rockwell Automation offers their PowerFlex line of VFDs in compact, standard, and premium models for applications from small to large horsepower. The presentation reviews VFD components, operations, applications in industries, and key selection factors.

Control loading-for-simulation-en

Wittenstein Aerospace & Simulation is a leading provider of control loading technology for aerospace and simulation markets. They design, develop, and produce haptic control systems using integrated servo motors, electronics, and software. Wittenstein offers modular control loading devices in various sizes to provide wide ranges of torque and speed. Their systems provide realistic force feedback and are used in flight simulators, mission trainers, and aircraft test beds.

Servo Motors Adjust

Servo Motors Adjust is a company that specializes in repairing servo motors and high-speed motors. They provide a 24-hour messenger service for quick repairs and can exchange motors to reduce downtime. Their highly trained technicians can repair motors from many major brands to save customers 50-85% compared to the cost of new motors. They also offer predictive testing, vibration analysis, and training to help customers maintain equipment efficiently.

Iai scon ca_specsheet

This document summarizes new and improved functions of SCON controllers for linear servo actuators. Key points include:

1) An offboard tuning function allows increasing actuator load capacity and acceleration/deceleration by automatically setting optimal gain according to the load. It provides benefits such as increasing maximum payload and speed.

2) The controllers now support many major field networks for simple, wire-saving connections to various equipment. Operations can be done by specifying positions or direct numerical values.

3) A new vibration control function suppresses vibration of workpieces attached to the actuator, shortening wait times and reducing cycle times.

Variable Frequency Drives

- Variable frequency drives (VFDs) allow the speed of AC motors to be varied by changing the frequency of the power supplied to the motor. VFDs first convert AC power to DC, then use an inverter to convert the DC back to variable frequency AC to control motor speed.

- The main components of a VFD are a rectifier to convert AC to DC, a DC bus to store the DC power, and an inverter to convert the DC back to variable frequency AC for the motor. Pulse width modulation is used to generate an AC waveform from the DC for motor control.

- VFDs allow parameters like maximum frequency, acceleration/deceleration rates, and torque boost to be set.

Cac ung dung bien tan lsis trong thuc te dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.org

Extrusion Thermoforming Line

The project involved retrofitting an existing plastic extrusion line with an updated control system. A vendor supplied new controls, interfaces, and PLCs to replace 15 existing drives and programmed the PLC. Installation and wiring was completed in 5 days, 2 days ahead of schedule. The line includes 4 extruder/melt pump combinations and controls casting, pull, and thermoforming processes. Operators use 5 touch screens to monitor and control the line. The retrofit allows melt pumps and extruders to restart while the line is running, improving operations.

Chapter1

This document provides an introduction to automation, including definitions, types, and reasons for automating. It discusses the basic elements of an automated system, which consist of actuators, controllers, and sensors. Different types of automation are described, including hard automation, soft automation, fixed automation, programmable automation, and flexible automation. Reasons for automating include increasing labor productivity, reducing labor costs, improving worker safety, and improving product quality. The document also discusses production quantity, product variety, and part/product complexity as factors related to automation.

Lecture 2 Wind Energy Course

This presentation contains,

i. Basics of Control Systems,

ii. Wind Turbine Controls

iii. Basics about Wind Farm and Control

iv. Wind Turbine Gearbox

v. Wind Turbine Generator

vi. Grids

18EE81_PSOC_8th Semester.pptx

This document discusses power system operation and control. It defines the different operating states of a power system as normal, alert, emergency, extremis, and restorative. The objectives of power system control are to meet changing demand, maintain sufficient reserves, ensure power quality, and supply energy at minimum cost. Preventive and emergency controls are used to maintain reliable operation and bring the system back to normal or alert states if needed. Key concepts for reliable operation include balancing real and reactive power, thermal limits, stability, and preparing for emergencies. Energy management centers coordinate controls across the power grid.

CCC_Turbomachinery_Controls_System.pdf

The document provides information about CCC, a controls company dedicated to making turbomachinery operation safe and efficient. It discusses CCC's products and control solutions for compressors, including antisurge controls and series of controller products. The document also describes different types of compressors and factors that can lead to surge, outlining CCC's business in advanced constraint control to widen the stable operating zone of compressors.

Electric submersible pump(esp)

An electrical submersible pump (ESP) is used to increase the pressure of well fluid and push it to the surface from deeper wells. It consists of a subsurface electric motor, seal section to connect the motor to multiple centrifugal pump stages, and an electric cable. The motor turns at high rpm to power the pump stages, each with an impeller and diffuser, to boost the fluid pressure stage by stage until it reaches the surface. ESPs provide high production volumes but require high voltages and more maintenance due to wear from sand and fluids. They are advantageous for deep wells but can have issues with sand and require careful installation and operation.

BP[1] Copy![BP[1] Copy](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![BP[1] Copy](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

1) The document describes several automation projects completed by MCM including assembly lines for ballast production, pipe bending, foam cutting, and exhaust pipe assembly with insulation.

2) Key features of the automation projects include use of pallets, pneumatic control systems, simultaneous operations at multiple stations, and modular designs allowing for increased productivity.

3) One project includes an 8-station transfer line that performs three successive operations to assemble insulated exhaust pipes at a rate of 6 pieces per minute. Another project utilizes a 10-station line to build core-coil subassemblies for ballasts.

SitrackVibes - Nuclear

The MPN100 system allows for real-time monitoring and failure detection of rotating machines in the nuclear industry to improve efficiency and reduce costs. It performs automatic analysis to detect potential failures like unbalance, misalignment, bearing and gear wear. This early failure detection allows for optimized maintenance and avoidance of catastrophic failures. The system uses various sensors and analyzes data using proprietary algorithms to monitor conditions and detect issues in nuclear power plants, experimental reactors, and other nuclear facilities and equipment.

Boeing Poster

The 416 group at Boeing designed an automated system to replace inserts in large end mills used to machine titanium aircraft parts. The system includes a carousel that stores 85 inserts, a pneumatic arm that removes inserts from the mill and places them in the carousel, and a screwdriver operated by servo motors that loosens and tightens inserts. A linear actuator moves the end mill into position and a stepper motor rotates it. The system is controlled by PLCs and an HMI interface to automate the time-consuming process of replacing inserts.

Alignment.pptx

This document provides an overview of precision laser shaft alignment using the RotAlign Touch tool. It discusses the benefits of precision alignment, including increased uptime and reduced energy consumption. It then describes shaft alignment principles and how laser alignment works. The document reviews the key components and functionality of the Fluke shaft alignment tool, outlining a step-by-step process for setting up the machine, taking measurements, diagnosing faults, and making corrections to the alignment. Additional topics covered include soft foot checking and what to look for in a shaft alignment tool.

More Related Content

What's hot

Servo motor and AVR Atmel Atmega 16

The document discusses how to configure timers on an Arduino to generate pulse-width modulated (PWM) signals for controlling servo motors. It explains that servo motors use PWM signals of varying pulse widths to control angular position precisely. It then provides code examples and explanations for setting up timer 1 on an Arduino in fast PWM mode at 50Hz to generate the necessary PWM signals, including setting the prescaler, waveform generation mode, and compare value. It also gives examples of PWM pulse widths needed to control a servo at different angles.

Mitsubishi inverter fr-e700 catalog-dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.vn

OneGear SMC 15kV Soft Starter

The document describes Rockwell Automation's OneGear medium voltage arc resistant soft starter for 10-15kV motors up to 11MW. It allows controlled acceleration and deceleration of motors to minimize wear while reducing energy consumption. Key features include arc flash protection, flexible control options, integral bypass, and easy replacement of components. Applications include pumps, chillers, compressors, and more. It provides intelligence, performance, flexibility, diagnostics and communications.

Mitsubishi inverter freqrol-a700 series dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.vn

Limitorque QX Electronic Actuator User Instructions

The Flowserve Limitorque QX quarter-turn smart electronic valve actuator continues the legacy of the industry’s state-of-the-art, non-intrusive, multi-turn MX actuator by including an absolute encoder for tracking position without the use of troublesome batteries. The QX design provides enhanced safety and reduced downtime through improved diagnostics, built-in self-test (BIST) features and LimiGard™ fault protection.

The QX design builds on more than 10 years of experience with proven Limitorque MX technology - the first generation double-sealed electronic valve actuator from Flowserve designed to provide control, ease of use and accuracy. The QX includes all the user-preferred features of the MX in a quarter-turn smart actuator package. It is the only non-intrusive, double-sealed quarter-turn actuator to display the Limitorque brand.

Thông số kỹ thuật bộ điều khiển tốc độ DKM catalogue speed control DKM

Thông số kỹ thuật bộ điều khiển tốc độ DKM catalogue speed control DKMCông ty cổ phần OKS | Tổng thầu thi công Nhà máy GMP, Tổng thầu thi công Nhà kho GSP

1. The document provides specifications for DKM speed control motors and controllers, including the FX1000A digital type system, DSK socket type system, and technical specifications.

2. It describes speed control methods, features of the FX1000A and DSK systems like easy connection and operation, and general technical specifications for controllers.

3. Tables provide motor line-up details, output capacities, frame sizes, power voltages, and connection diagrams for understanding specifications.Variable Frequency Drives

This document summarizes a presentation on variable frequency drives (VFDs). VFDs vary the speed of 3-phase AC motors by converting AC power to DC and then converting it back to variable voltage/frequency AC. They allow constant and variable torque motor loads to operate at variable speeds. Applications include pumps, fans, compressors. Selecting a VFD depends on the motor's current, kW rating, type of machine/application, and required functionality/controls. Rockwell Automation offers their PowerFlex line of VFDs in compact, standard, and premium models for applications from small to large horsepower. The presentation reviews VFD components, operations, applications in industries, and key selection factors.

Control loading-for-simulation-en

Wittenstein Aerospace & Simulation is a leading provider of control loading technology for aerospace and simulation markets. They design, develop, and produce haptic control systems using integrated servo motors, electronics, and software. Wittenstein offers modular control loading devices in various sizes to provide wide ranges of torque and speed. Their systems provide realistic force feedback and are used in flight simulators, mission trainers, and aircraft test beds.

Servo Motors Adjust

Servo Motors Adjust is a company that specializes in repairing servo motors and high-speed motors. They provide a 24-hour messenger service for quick repairs and can exchange motors to reduce downtime. Their highly trained technicians can repair motors from many major brands to save customers 50-85% compared to the cost of new motors. They also offer predictive testing, vibration analysis, and training to help customers maintain equipment efficiently.

Iai scon ca_specsheet

This document summarizes new and improved functions of SCON controllers for linear servo actuators. Key points include:

1) An offboard tuning function allows increasing actuator load capacity and acceleration/deceleration by automatically setting optimal gain according to the load. It provides benefits such as increasing maximum payload and speed.

2) The controllers now support many major field networks for simple, wire-saving connections to various equipment. Operations can be done by specifying positions or direct numerical values.

3) A new vibration control function suppresses vibration of workpieces attached to the actuator, shortening wait times and reducing cycle times.

Variable Frequency Drives

- Variable frequency drives (VFDs) allow the speed of AC motors to be varied by changing the frequency of the power supplied to the motor. VFDs first convert AC power to DC, then use an inverter to convert the DC back to variable frequency AC to control motor speed.

- The main components of a VFD are a rectifier to convert AC to DC, a DC bus to store the DC power, and an inverter to convert the DC back to variable frequency AC for the motor. Pulse width modulation is used to generate an AC waveform from the DC for motor control.

- VFDs allow parameters like maximum frequency, acceleration/deceleration rates, and torque boost to be set.

Cac ung dung bien tan lsis trong thuc te dienhathe.vn

Khoa Học - Kỹ Thuật & Giải Trí: http://phongvan.org

Tài Liệu Khoa Học Kỹ Thuật: http://tailieukythuat.info

Thiết bị Điện Công Nghiệp - Điện Hạ Thế: http://dienhathe.org

What's hot (12)

Mitsubishi inverter freqrol-a700 series dienhathe.vn

Mitsubishi inverter freqrol-a700 series dienhathe.vn

Limitorque QX Electronic Actuator User Instructions

Limitorque QX Electronic Actuator User Instructions

Thông số kỹ thuật bộ điều khiển tốc độ DKM catalogue speed control DKM

Thông số kỹ thuật bộ điều khiển tốc độ DKM catalogue speed control DKM

Cac ung dung bien tan lsis trong thuc te dienhathe.vn

Cac ung dung bien tan lsis trong thuc te dienhathe.vn

Similar to Pipe laying barge

Extrusion Thermoforming Line

The project involved retrofitting an existing plastic extrusion line with an updated control system. A vendor supplied new controls, interfaces, and PLCs to replace 15 existing drives and programmed the PLC. Installation and wiring was completed in 5 days, 2 days ahead of schedule. The line includes 4 extruder/melt pump combinations and controls casting, pull, and thermoforming processes. Operators use 5 touch screens to monitor and control the line. The retrofit allows melt pumps and extruders to restart while the line is running, improving operations.

Chapter1

This document provides an introduction to automation, including definitions, types, and reasons for automating. It discusses the basic elements of an automated system, which consist of actuators, controllers, and sensors. Different types of automation are described, including hard automation, soft automation, fixed automation, programmable automation, and flexible automation. Reasons for automating include increasing labor productivity, reducing labor costs, improving worker safety, and improving product quality. The document also discusses production quantity, product variety, and part/product complexity as factors related to automation.

Lecture 2 Wind Energy Course

This presentation contains,

i. Basics of Control Systems,

ii. Wind Turbine Controls

iii. Basics about Wind Farm and Control

iv. Wind Turbine Gearbox

v. Wind Turbine Generator

vi. Grids

18EE81_PSOC_8th Semester.pptx

This document discusses power system operation and control. It defines the different operating states of a power system as normal, alert, emergency, extremis, and restorative. The objectives of power system control are to meet changing demand, maintain sufficient reserves, ensure power quality, and supply energy at minimum cost. Preventive and emergency controls are used to maintain reliable operation and bring the system back to normal or alert states if needed. Key concepts for reliable operation include balancing real and reactive power, thermal limits, stability, and preparing for emergencies. Energy management centers coordinate controls across the power grid.

CCC_Turbomachinery_Controls_System.pdf

The document provides information about CCC, a controls company dedicated to making turbomachinery operation safe and efficient. It discusses CCC's products and control solutions for compressors, including antisurge controls and series of controller products. The document also describes different types of compressors and factors that can lead to surge, outlining CCC's business in advanced constraint control to widen the stable operating zone of compressors.

Electric submersible pump(esp)

An electrical submersible pump (ESP) is used to increase the pressure of well fluid and push it to the surface from deeper wells. It consists of a subsurface electric motor, seal section to connect the motor to multiple centrifugal pump stages, and an electric cable. The motor turns at high rpm to power the pump stages, each with an impeller and diffuser, to boost the fluid pressure stage by stage until it reaches the surface. ESPs provide high production volumes but require high voltages and more maintenance due to wear from sand and fluids. They are advantageous for deep wells but can have issues with sand and require careful installation and operation.

BP[1] Copy![BP[1] Copy](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![BP[1] Copy](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

1) The document describes several automation projects completed by MCM including assembly lines for ballast production, pipe bending, foam cutting, and exhaust pipe assembly with insulation.

2) Key features of the automation projects include use of pallets, pneumatic control systems, simultaneous operations at multiple stations, and modular designs allowing for increased productivity.

3) One project includes an 8-station transfer line that performs three successive operations to assemble insulated exhaust pipes at a rate of 6 pieces per minute. Another project utilizes a 10-station line to build core-coil subassemblies for ballasts.

SitrackVibes - Nuclear

The MPN100 system allows for real-time monitoring and failure detection of rotating machines in the nuclear industry to improve efficiency and reduce costs. It performs automatic analysis to detect potential failures like unbalance, misalignment, bearing and gear wear. This early failure detection allows for optimized maintenance and avoidance of catastrophic failures. The system uses various sensors and analyzes data using proprietary algorithms to monitor conditions and detect issues in nuclear power plants, experimental reactors, and other nuclear facilities and equipment.

Boeing Poster

The 416 group at Boeing designed an automated system to replace inserts in large end mills used to machine titanium aircraft parts. The system includes a carousel that stores 85 inserts, a pneumatic arm that removes inserts from the mill and places them in the carousel, and a screwdriver operated by servo motors that loosens and tightens inserts. A linear actuator moves the end mill into position and a stepper motor rotates it. The system is controlled by PLCs and an HMI interface to automate the time-consuming process of replacing inserts.

Alignment.pptx

This document provides an overview of precision laser shaft alignment using the RotAlign Touch tool. It discusses the benefits of precision alignment, including increased uptime and reduced energy consumption. It then describes shaft alignment principles and how laser alignment works. The document reviews the key components and functionality of the Fluke shaft alignment tool, outlining a step-by-step process for setting up the machine, taking measurements, diagnosing faults, and making corrections to the alignment. Additional topics covered include soft foot checking and what to look for in a shaft alignment tool.

Chapter1_Introduction_to_Control_System.pptx

This document provides an overview of control systems. It defines a control system and its basic components. The key differences between open loop and closed loop control schemes are explained. The three main objectives of control system design and analysis are described as producing the desired transient response, reducing steady-state error, and achieving stability. Examples of control systems applications are given across various domains like ships, aircraft, manufacturing processes. The response characteristics of a control system like input, output, transient response and steady-state response are explained. The advantages and disadvantages of open loop and closed loop systems are compared. Computer aided design using simulation software is introduced as an effective way to analyze, design and test control systems.

Inst maint practices

This document discusses instrument maintenance practices at National Fertilizers Limited, a chemical process industry. It outlines the importance of instrumentation in process industries and describes various types of control loops used. It then discusses different types of maintenance practices including day-to-day, preventative, shutdown, and breakdown maintenance. Finally, it outlines upgrades made to instrumentation systems, including implementing a distributed control system and programmable logic controllers, to improve reliability, efficiency, and use of latest technologies.

Inst maint practices

This document discusses instrument maintenance practices at National Fertilizers Limited, a chemical process industry. It outlines the importance of instrumentation in process industries and describes various types of control loops used. It then discusses different types of maintenance practices including day-to-day, preventative, shutdown, and breakdown maintenance. Finally, it outlines upgrades made to instrumentation systems, including replacing old pneumatic and single loop controllers with a distributed control system and programmable logic controllers to improve reliability, efficiency, and optimization.

85 0066-b rev 2 hq ultimate series installation

The document provides contact information for HydroQuip's Technical Support staff, including their address, website, email, and phone and fax numbers. It encourages readers to contact Technical Support if they encounter any problems or need assistance. It also notes that "THE SMART CHOICE" is HydroQuip's slogan.

85 0066-b hq ultimate series installation

This document provides instructions for troubleshooting problems with the Ultimate Series spa control system. It describes how to identify error messages through flashing dots on the temperature display and illuminated LED indicators. Instructions are provided for adjusting the pressure switch if it is activated when the pump is not running. The document also covers general installation considerations for Hydro-Quip solid-state control packs.

Closed loop control of converter fed motor

This document discusses closed loop control of DC motors. It describes how closed loop control uses feedback to regulate motor speed by varying the voltage applied to the motor. It explains four quadrant chopper control and how duty cycle controls motor speed. Closed loop speed control and closed loop field control methods are presented. The feedback loop is described as taking the output into consideration to adjust performance to meet the desired result. The key differences between open loop and closed loop systems are outlined. Applications and advantages/disadvantages of closed loop control are also summarized.

Hydro Power Plant Auxaleries

This document provides information on the various auxiliary systems used in hydro power plants, including:

- Braking and jacking, compressed air, heating/cooling, governing, cooling water, drainage, and mechanical auxiliary systems.

- Electrical auxiliary systems like bus ducts, transformers, cables, switchgear, protection systems, and control/monitoring panels.

- Operation procedures including pre-start checks, normal start/stop sequences, synchronization, and emergency handling.

- Key components of sub-systems like pressure tanks, compressors, pumps, valves and details of lubrication, ventilation, fire protection and crane systems.

Work History 2008

The document provides a work history summarizing the applicant's experience from 2008 to current working in various operator roles at a nuclear installation. Some of the key responsibilities included monitoring and operating tertiary cooling, nuclear auxiliary, and turbine systems to ensure correct plant parameters and apply corrective actions when needed. The applicant also has experience as a principal nuclear plant operator responsible for permit to work applications and on-job training. Additional experience includes control room operator duties for a waste treatment plant such as remote operation and monitoring of systems. Relevant skills include various operating regulations, permit to work authorizations, hazardous materials handling, and firefighting.

Oil field equipment the part two (2)pptx

The document discusses various types of oil field production equipment. It describes artificial lift methods used when reservoir pressure is not high enough to lift fluids to the surface, including gas lift, sucker rod pumping, submersible electric pumping, and subsurface hydraulic pumping. It also discusses water injection and disposal, as water is usually associated with oil production. The document outlines flow control equipment used at the surface like chokes, safety valves, and pressure regulators to control flow rates from producing wells. It provides details on choke types, components, and advantages of positive/fixed and adjustable chokes.

Advancement-in-spinning-Techniques-seminar-report-1.ppt

1. Recent developments in blowroom machinery aim to improve fiber opening, cleaning, and preparation for downstream processes. Automatic bale openers, mote knives with suction, and optical/acoustic sorters help remove contaminants.

2. Modern carding achieves a high degree of cleaning, around 90-95%. Developments include improved feeding, multiple taker-ins, post-carding cleaning, and auto-leveling for more consistent sliver quality.

3. Drawframe developments enhance sliver evenness and blending through automatic break draft setting, tension measuring, and short-term auto-leveling. Cameras also monitor sliver quality.

4. Simplex/speed frame innovations

Similar to Pipe laying barge (20)

Advancement-in-spinning-Techniques-seminar-report-1.ppt

Advancement-in-spinning-Techniques-seminar-report-1.ppt

Recently uploaded

Embedded machine learning-based road conditions and driving behavior monitoring

Car accident rates have increased in recent years, resulting in losses in human lives, properties, and other financial costs. An embedded machine learning-based system is developed to address this critical issue. The system can monitor road conditions, detect driving patterns, and identify aggressive driving behaviors. The system is based on neural networks trained on a comprehensive dataset of driving events, driving styles, and road conditions. The system effectively detects potential risks and helps mitigate the frequency and impact of accidents. The primary goal is to ensure the safety of drivers and vehicles. Collecting data involved gathering information on three key road events: normal street and normal drive, speed bumps, circular yellow speed bumps, and three aggressive driving actions: sudden start, sudden stop, and sudden entry. The gathered data is processed and analyzed using a machine learning system designed for limited power and memory devices. The developed system resulted in 91.9% accuracy, 93.6% precision, and 92% recall. The achieved inference time on an Arduino Nano 33 BLE Sense with a 32-bit CPU running at 64 MHz is 34 ms and requires 2.6 kB peak RAM and 139.9 kB program flash memory, making it suitable for resource-constrained embedded systems.

IEEE Aerospace and Electronic Systems Society as a Graduate Student Member

IEEE Aerospace and Electronic Systems Society as a Graduate Student Member

Harnessing WebAssembly for Real-time Stateless Streaming Pipelines

Traditionally, dealing with real-time data pipelines has involved significant overhead, even for straightforward tasks like data transformation or masking. However, in this talk, we’ll venture into the dynamic realm of WebAssembly (WASM) and discover how it can revolutionize the creation of stateless streaming pipelines within a Kafka (Redpanda) broker. These pipelines are adept at managing low-latency, high-data-volume scenarios.

22CYT12-Unit-V-E Waste and its Management.ppt

Introduction- e - waste – definition - sources of e-waste– hazardous substances in e-waste - effects of e-waste on environment and human health- need for e-waste management– e-waste handling rules - waste minimization techniques for managing e-waste – recycling of e-waste - disposal treatment methods of e- waste – mechanism of extraction of precious metal from leaching solution-global Scenario of E-waste – E-waste in India- case studies.

BRAIN TUMOR DETECTION for seminar ppt.pdf

BRAIN TUMOR DETECTION

AND CLASSIFICATION USING

ARTIFICIAL INTELLIGENCE

Hematology Analyzer Machine - Complete Blood Count

The CBC machine is a common diagnostic tool used by doctors to measure a patient's red blood cell count, white blood cell count and platelet count. The machine uses a small sample of the patient's blood, which is then placed into special tubes and analyzed. The results of the analysis are then displayed on a screen for the doctor to review. The CBC machine is an important tool for diagnosing various conditions, such as anemia, infection and leukemia. It can also help to monitor a patient's response to treatment.

哪里办理(csu毕业证书)查尔斯特大学毕业证硕士学历原版一模一样

原版一模一样【微信:741003700 】【(csu毕业证书)查尔斯特大学毕业证硕士学历】【微信:741003700 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原海外各大学 Bachelor Diploma degree, Master Degree Diploma

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

学校原版美国波士顿大学毕业证学历学位证书原版一模一样

原版一模一样【微信:741003700 】【美国波士顿大学毕业证学历学位证书】【微信:741003700 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原海外各大学 Bachelor Diploma degree, Master Degree Diploma

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

Casting-Defect-inSlab continuous casting.pdf

Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting

Advanced control scheme of doubly fed induction generator for wind turbine us...

This paper describes a speed control device for generating electrical energy on an electricity network based on the doubly fed induction generator (DFIG) used for wind power conversion systems. At first, a double-fed induction generator model was constructed. A control law is formulated to govern the flow of energy between the stator of a DFIG and the energy network using three types of controllers: proportional integral (PI), sliding mode controller (SMC) and second order sliding mode controller (SOSMC). Their different results in terms of power reference tracking, reaction to unexpected speed fluctuations, sensitivity to perturbations, and resilience against machine parameter alterations are compared. MATLAB/Simulink was used to conduct the simulations for the preceding study. Multiple simulations have shown very satisfying results, and the investigations demonstrate the efficacy and power-enhancing capabilities of the suggested control system.

Unit-III-ELECTROCHEMICAL STORAGE DEVICES.ppt

Batteries -Introduction – Types of Batteries – discharging and charging of battery - characteristics of battery –battery rating- various tests on battery- – Primary battery: silver button cell- Secondary battery :Ni-Cd battery-modern battery: lithium ion battery-maintenance of batteries-choices of batteries for electric vehicle applications.

Fuel Cells: Introduction- importance and classification of fuel cells - description, principle, components, applications of fuel cells: H2-O2 fuel cell, alkaline fuel cell, molten carbonate fuel cell and direct methanol fuel cells.

ISPM 15 Heat Treated Wood Stamps and why your shipping must have one

For International shipping and maritime laws all wood must contain the ISPM 15 Stamp. Here is how and why.

Comparative analysis between traditional aquaponics and reconstructed aquapon...

The aquaponic system of planting is a method that does not require soil usage. It is a method that only needs water, fish, lava rocks (a substitute for soil), and plants. Aquaponic systems are sustainable and environmentally friendly. Its use not only helps to plant in small spaces but also helps reduce artificial chemical use and minimizes excess water use, as aquaponics consumes 90% less water than soil-based gardening. The study applied a descriptive and experimental design to assess and compare conventional and reconstructed aquaponic methods for reproducing tomatoes. The researchers created an observation checklist to determine the significant factors of the study. The study aims to determine the significant difference between traditional aquaponics and reconstructed aquaponics systems propagating tomatoes in terms of height, weight, girth, and number of fruits. The reconstructed aquaponics system’s higher growth yield results in a much more nourished crop than the traditional aquaponics system. It is superior in its number of fruits, height, weight, and girth measurement. Moreover, the reconstructed aquaponics system is proven to eliminate all the hindrances present in the traditional aquaponics system, which are overcrowding of fish, algae growth, pest problems, contaminated water, and dead fish.

ACEP Magazine edition 4th launched on 05.06.2024

This document provides information about the third edition of the magazine "Sthapatya" published by the Association of Civil Engineers (Practicing) Aurangabad. It includes messages from current and past presidents of ACEP, memories and photos from past ACEP events, information on life time achievement awards given by ACEP, and a technical article on concrete maintenance, repairs and strengthening. The document highlights activities of ACEP and provides a technical educational article for members.

Optimizing Gradle Builds - Gradle DPE Tour Berlin 2024

Sinan from the Delivery Hero mobile infrastructure engineering team shares a deep dive into performance acceleration with Gradle build cache optimizations. Sinan shares their journey into solving complex build-cache problems that affect Gradle builds. By understanding the challenges and solutions found in our journey, we aim to demonstrate the possibilities for faster builds. The case study reveals how overlapping outputs and cache misconfigurations led to significant increases in build times, especially as the project scaled up with numerous modules using Paparazzi tests. The journey from diagnosing to defeating cache issues offers invaluable lessons on maintaining cache integrity without sacrificing functionality.

Literature Review Basics and Understanding Reference Management.pptx

Three-day training on academic research focuses on analytical tools at United Technical College, supported by the University Grant Commission, Nepal. 24-26 May 2024

Recently uploaded (20)

Embedded machine learning-based road conditions and driving behavior monitoring

Embedded machine learning-based road conditions and driving behavior monitoring

Engineering Drawings Lecture Detail Drawings 2014.pdf

Engineering Drawings Lecture Detail Drawings 2014.pdf

IEEE Aerospace and Electronic Systems Society as a Graduate Student Member

IEEE Aerospace and Electronic Systems Society as a Graduate Student Member

Harnessing WebAssembly for Real-time Stateless Streaming Pipelines

Harnessing WebAssembly for Real-time Stateless Streaming Pipelines

Hematology Analyzer Machine - Complete Blood Count

Hematology Analyzer Machine - Complete Blood Count

Advanced control scheme of doubly fed induction generator for wind turbine us...

Advanced control scheme of doubly fed induction generator for wind turbine us...

ML Based Model for NIDS MSc Updated Presentation.v2.pptx

ML Based Model for NIDS MSc Updated Presentation.v2.pptx

ISPM 15 Heat Treated Wood Stamps and why your shipping must have one

ISPM 15 Heat Treated Wood Stamps and why your shipping must have one

Comparative analysis between traditional aquaponics and reconstructed aquapon...

Comparative analysis between traditional aquaponics and reconstructed aquapon...

Optimizing Gradle Builds - Gradle DPE Tour Berlin 2024

Optimizing Gradle Builds - Gradle DPE Tour Berlin 2024

Literature Review Basics and Understanding Reference Management.pptx

Literature Review Basics and Understanding Reference Management.pptx

Pipe laying barge

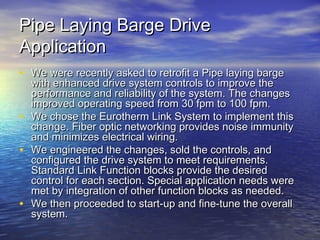

- 1. Pipe Laying Barge DrivePipe Laying Barge Drive ApplicationApplication • We were recently asked to retrofit a Pipe laying bargeWe were recently asked to retrofit a Pipe laying barge with enhanced drive system controls to improve thewith enhanced drive system controls to improve the performance and reliability of the system. The changesperformance and reliability of the system. The changes improved operating speed from 30 fpm to 100 fpm.improved operating speed from 30 fpm to 100 fpm. • We chose the Eurotherm Link System to implement thisWe chose the Eurotherm Link System to implement this change. Fiber optic networking provides noise immunitychange. Fiber optic networking provides noise immunity and minimizes electrical wiring.and minimizes electrical wiring. • We engineered the changes, sold the controls, andWe engineered the changes, sold the controls, and configured the drive system to meet requirements.configured the drive system to meet requirements. Standard Link Function blocks provide the desiredStandard Link Function blocks provide the desired control for each section. Special application needs werecontrol for each section. Special application needs were met by integration of other function blocks as needed.met by integration of other function blocks as needed. • We then proceeded to start-up and fine-tune the overallWe then proceeded to start-up and fine-tune the overall system.system.

- 2. Main Crane for Pipe BargeMain Crane for Pipe Barge • The large crane in centerThe large crane in center aft is permanentlyaft is permanently mounted and can handlemounted and can handle any requirement forany requirement for loading or offloadingloading or offloading equipment from theequipment from the Barge.Barge. • It is not part of the systemIt is not part of the system we worked on, but iswe worked on, but is used to install all theused to install all the heavy equipment on-heavy equipment on- board.board.

- 3. System Components:System Components: Forward & Aft Tensioners,Forward & Aft Tensioners, Straightener-Aligner, & ReelStraightener-Aligner, & Reel

- 4. System integrationSystem integration • The computerized Drive system selects the masterThe computerized Drive system selects the master Tensioner by the first drive turned on, and for the reel byTensioner by the first drive turned on, and for the reel by the first reel drive turned on.the first reel drive turned on. • The Slave Tensioner Drives look at the Master’s current,The Slave Tensioner Drives look at the Master’s current, and produce an output to assist the Master in controllingand produce an output to assist the Master in controlling the Pipe movement and Tension on the Pipe.the Pipe movement and Tension on the Pipe. • The Reel Motors all produce a torque based on theThe Reel Motors all produce a torque based on the operator set-point, to pull the pipe and bend it for windingoperator set-point, to pull the pipe and bend it for winding on the Reel. (Or holdback torque when paying out, toon the Reel. (Or holdback torque when paying out, to straighten the pipe.) The system runs with 2, 3 or 4straighten the pipe.) The system runs with 2, 3 or 4 motors active on the reel. The torque set-point, staticmotors active on the reel. The torque set-point, static and dynamic compensation, and trim feedback are alland dynamic compensation, and trim feedback are all scaled automatically depending on the number of motorsscaled automatically depending on the number of motors active.active. • The system can be run in 2 modes; Conventional speedThe system can be run in 2 modes; Conventional speed mode or Tension mode. Reel runs in speed mode, ormode or Tension mode. Reel runs in speed mode, or pipe can be stacked on board and welded as it pays out,pipe can be stacked on board and welded as it pays out, (Tension mode).(Tension mode).

- 5. Tensioner ControlTensioner Control • There are Two Tensioners,There are Two Tensioners, one fore and one aft unit.one fore and one aft unit. • Each Tensioner consists ofEach Tensioner consists of two tracks, (similar to Tanktwo tracks, (similar to Tank tracks), which have rubbertracks), which have rubber pads mounted on them. Thesepads mounted on them. These tracks close on the pipe to griptracks close on the pipe to grip it securely.it securely. • Each track has two 500HP DCEach track has two 500HP DC motors geared to the track.motors geared to the track. • There is one motor designatedThere is one motor designated as the master, and all otheras the master, and all other motors on the two Tensionersmotors on the two Tensioners are slaved to the master unit.are slaved to the master unit.

- 6. Motor & Gearboxes for PipeMotor & Gearboxes for Pipe Winding ReelWinding Reel • Workers guiding MotorWorkers guiding Motor assembly into place on-boardassembly into place on-board the barge, to Power the Reelthe barge, to Power the Reel for winding pipe. The reel canfor winding pipe. The reel can wind up 80 miles of 4”wind up 80 miles of 4” diameter, or 34 miles of 9”diameter, or 34 miles of 9” diameter Steel Pipe prior todiameter Steel Pipe prior to embarking.embarking. • The mission of the Barge is toThe mission of the Barge is to lay Pipelines for commerciallay Pipelines for commercial customers.customers. • The pipe on the reel is 9”The pipe on the reel is 9” diameter.diameter.

- 7. Motor Controls for systemMotor Controls for system • One of 12 500HP DCOne of 12 500HP DC Motor Controls in theMotor Controls in the Drive housing.Drive housing. • Four enclosures eachFour enclosures each house 3 of these Drivehouse 3 of these Drive units.units. • All 12 Drives and variousAll 12 Drives and various analogue and digital I/Oanalogue and digital I/O are networked to provideare networked to provide the system integration.the system integration. • A PLC is integrated intoA PLC is integrated into the system by anotherthe system by another contractor.contractor.

- 8. Reel in OperationReel in Operation • After commissioning theAfter commissioning the system, the operators aresystem, the operators are winding Pipe for a new job.winding Pipe for a new job. • The Pipe exits a straightener-The Pipe exits a straightener- aligner section before windingaligner section before winding on the reel. This section andon the reel. This section and both Tensioners move up andboth Tensioners move up and down with the wraps on thedown with the wraps on the reel.reel. • Tension of the Pipe is criticalTension of the Pipe is critical to prevent damage.to prevent damage. • The Pipe is straightened againThe Pipe is straightened again when paying out into thewhen paying out into the water.water.

- 9. Winding PipeWinding Pipe • As the jobAs the job progresses, theprogresses, the system must maintainsystem must maintain proper tension on theproper tension on the pipe to keep frompipe to keep from “dropping wraps”.“dropping wraps”. • Pipe windingPipe winding completed for this job,completed for this job, just prior tojust prior to embarking for job.embarking for job.

- 10. Stinger to Guide Pipe-LayingStinger to Guide Pipe-Laying • This assembly is attachedThis assembly is attached to the barge after the aftto the barge after the aft Tensioner to guide theTensioner to guide the pipe for proper Lay down.pipe for proper Lay down. When we arrive atWhen we arrive at location, it is loweredlocation, it is lowered below the water line.below the water line. • Another boat follows theAnother boat follows the barge to monitor thebarge to monitor the actual touchdown of theactual touchdown of the pipe with sonar monitor.pipe with sonar monitor.

- 11. Arrive at the job locationArrive at the job location • The job location is aThe job location is a drilling rig in the Gulf.drilling rig in the Gulf. We are attaching toWe are attaching to the well head andthe well head and running 16 miles of 10running 16 miles of 10 inch pipe.inch pipe.

- 12. News Media arrivalNews Media arrival • We were able to layWe were able to lay the pipe at speeds upthe pipe at speeds up to 101.6 fpm, which isto 101.6 fpm, which is a world record.a world record. • News mediaNews media documented the jobdocumented the job for publication andfor publication and company use.company use.

- 13. Job CompleteJob Complete • We completed the jobWe completed the job in just over 3 ½ days,in just over 3 ½ days, which was within thewhich was within the scheduled time.scheduled time. • This was in spite of aThis was in spite of a number of unusualnumber of unusual delays during thedelays during the process.process.

- 14. Computer Access and MonitoringComputer Access and Monitoring • The upper right window isThe upper right window is access to all modules inaccess to all modules in the system.the system. • The left hand window isThe left hand window is one of the module’sone of the module’s configurations opened forconfigurations opened for making changes tomaking changes to parameters while theparameters while the drives are running.drives are running. • The lower right window isThe lower right window is a list of parameters beinga list of parameters being continuously monitored incontinuously monitored in real-time.real-time.

- 15. Job ResultsJob Results • New Speed record for laying pipe fromNew Speed record for laying pipe from reel. Design spec is 90 fpm max reelreel. Design spec is 90 fpm max reel speed, we ran at 101.6 fpm.speed, we ran at 101.6 fpm. • We met or exceeded all the requirementsWe met or exceeded all the requirements for the system.for the system. • Drive controls worked with no changesDrive controls worked with no changes required to the system during Pipe-layrequired to the system during Pipe-lay operation.operation.