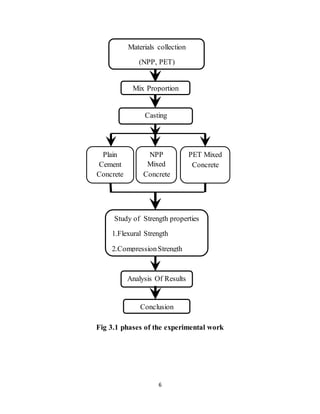

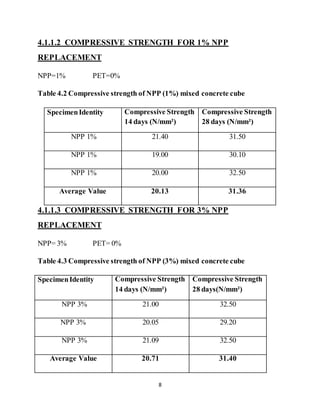

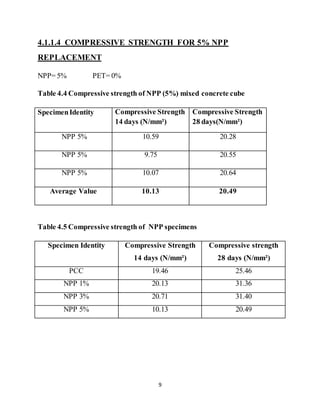

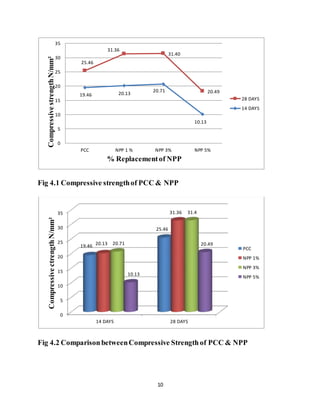

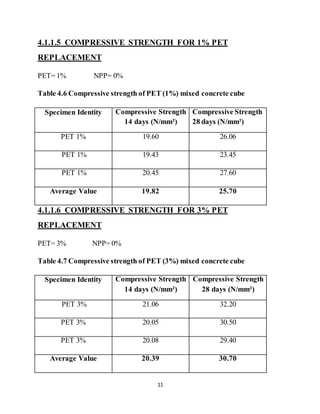

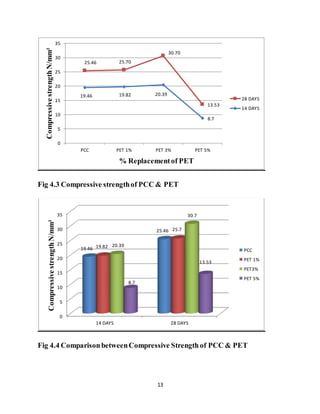

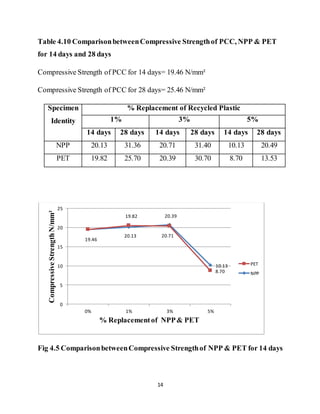

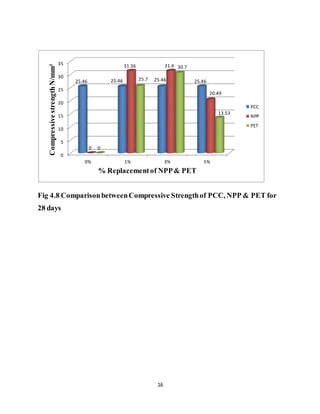

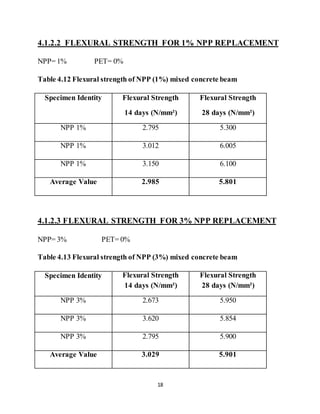

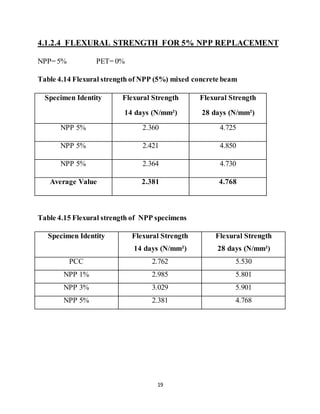

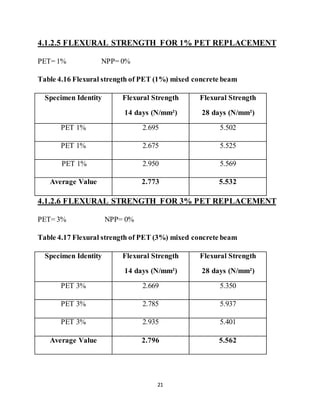

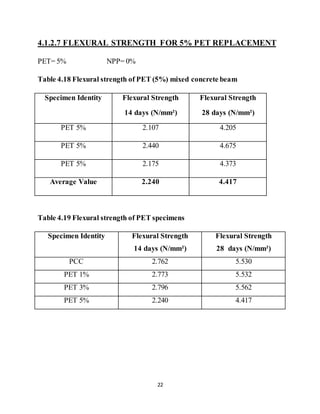

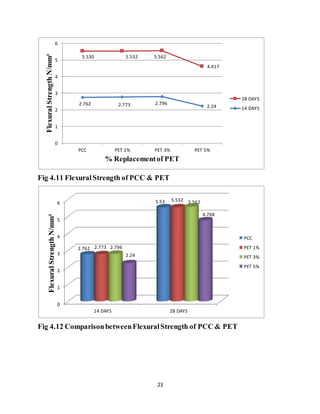

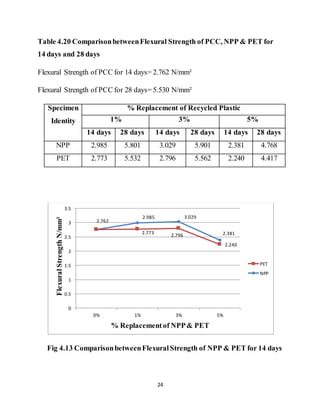

This document discusses a performance study on using recycled plastics in concrete. It begins with introductions to plastics waste and the need for the study. The experimental work involved collecting plastic materials, developing concrete mix designs replacing coarse aggregate with plastics, casting specimens, and testing them to determine compressive and flexural strengths at various plastic replacement levels. The results showed that compressive strengths generally increased at 1-3% plastic replacement levels compared to plain concrete but decreased at 5% replacement.