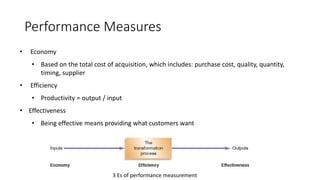

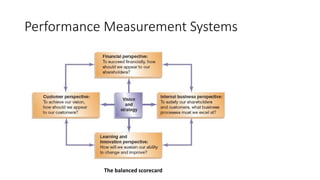

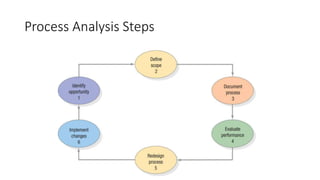

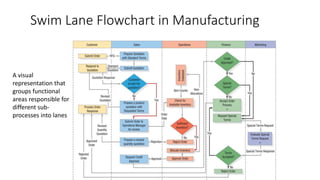

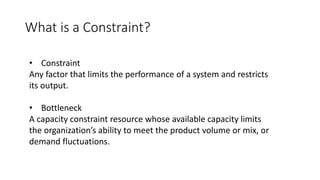

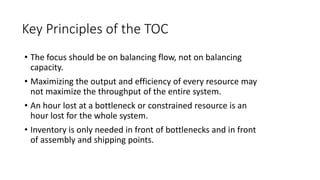

This document discusses performance measurement and process analysis. It defines key terms like performance measures, measurement systems, standards, and process improvement. Performance measurement plays a strategic role by linking strategy to action and influencing behavior. Measures include economy, efficiency, and effectiveness. Measurement systems like the balanced scorecard are discussed. Process analysis identifies improvement opportunities by mapping processes, flow charts, and identifying bottlenecks and constraints. The goal is continuous improvement through methods like benchmarking and reengineering.