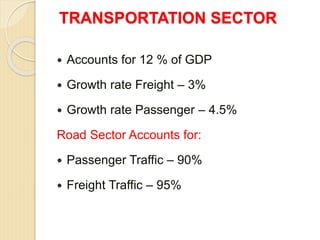

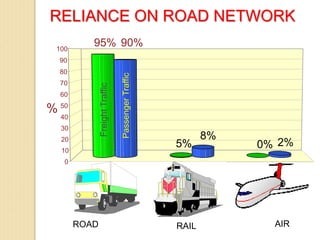

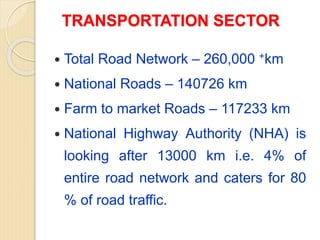

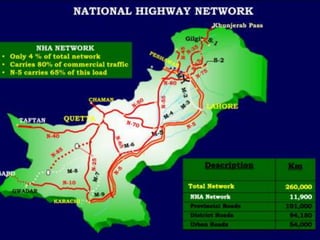

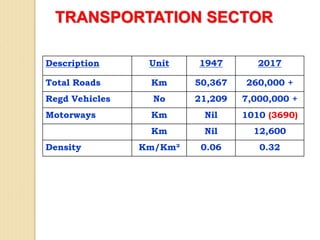

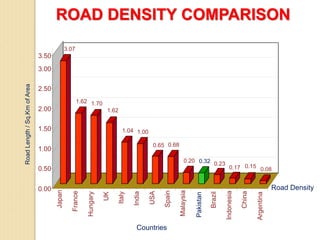

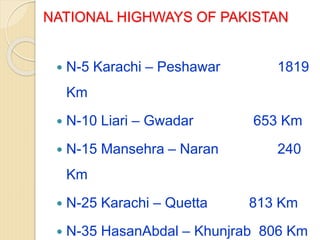

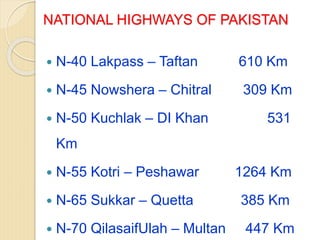

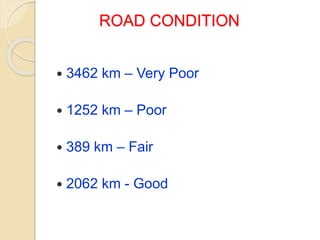

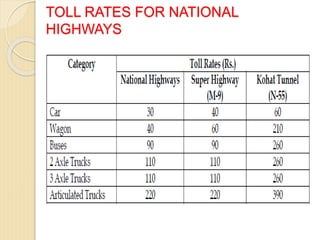

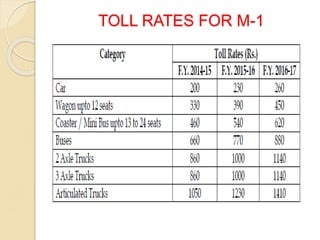

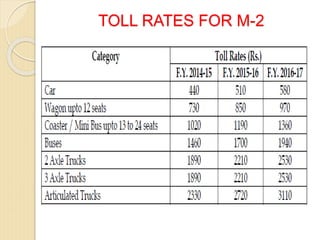

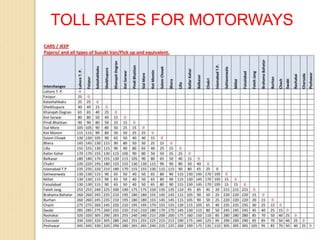

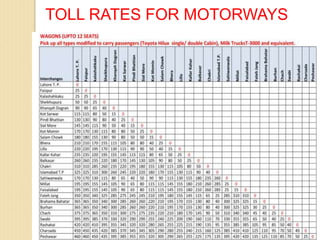

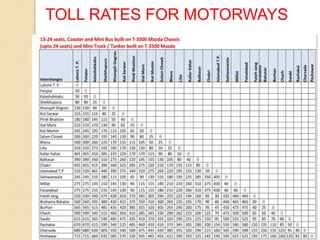

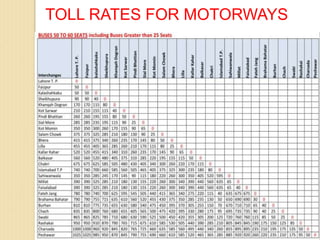

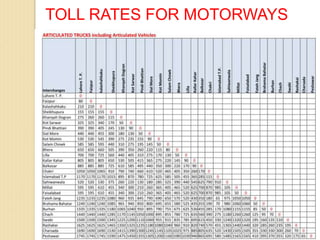

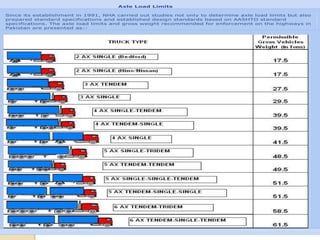

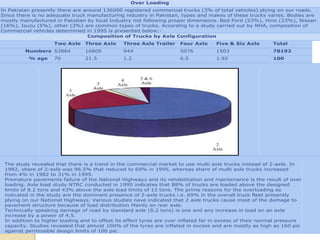

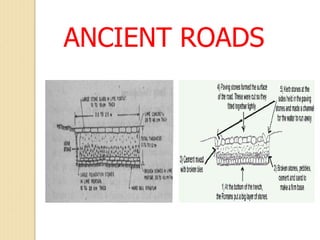

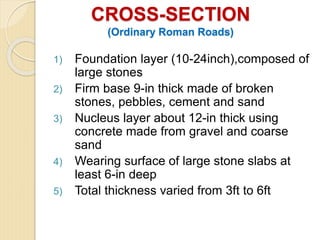

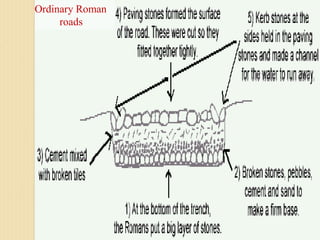

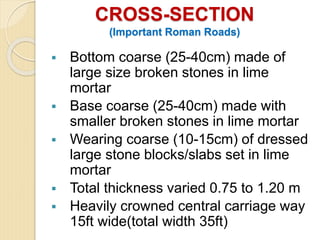

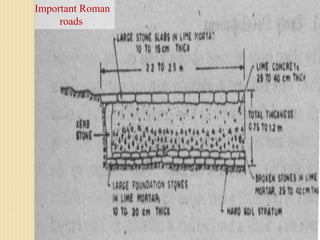

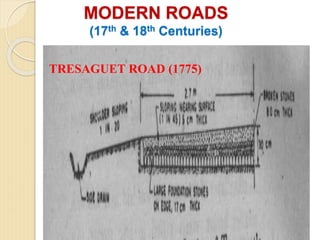

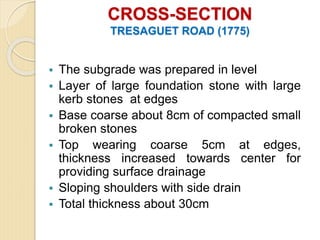

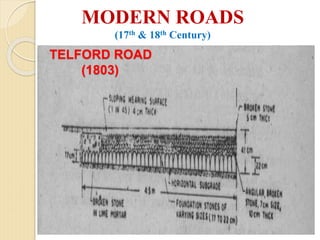

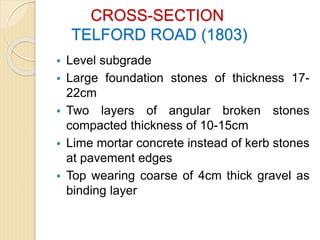

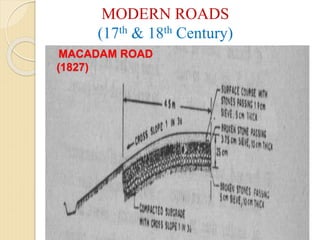

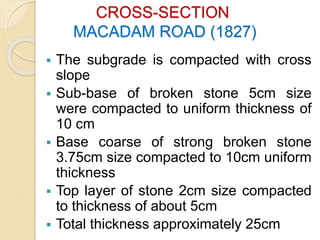

This document provides an overview of pavement design and analysis for a course at the National University of Science and Technology. It discusses the transportation sector in Pakistan, including its reliance on roads. It provides details on the national road network and toll rates. It also gives a historical background on pavement design, from ancient Roman and Macadam roads to modern developments. Key sections summarize pavement cross-sections from different eras, including Tresaguet roads, Telford roads, and Macadam roads.