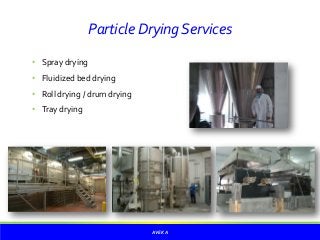

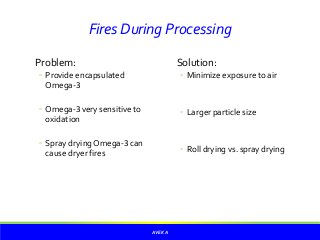

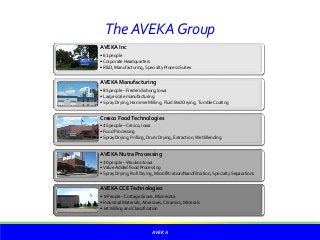

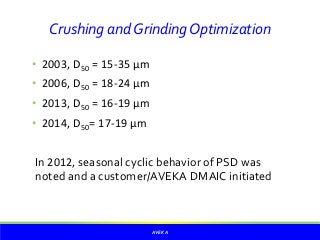

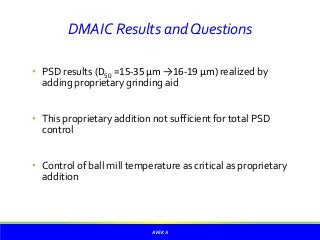

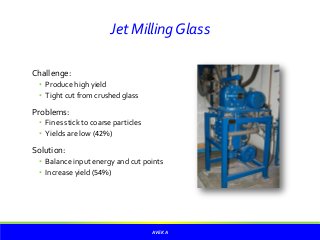

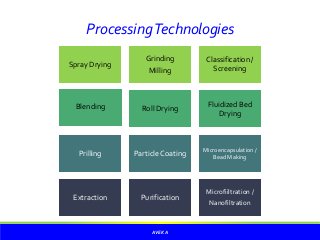

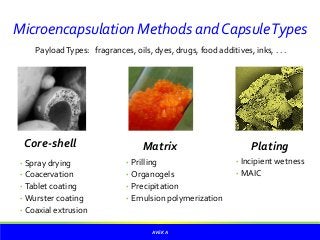

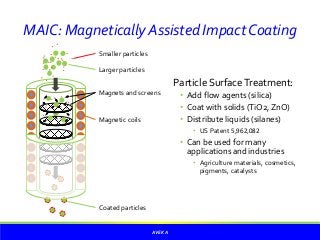

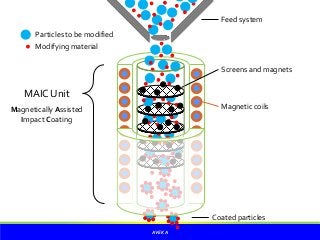

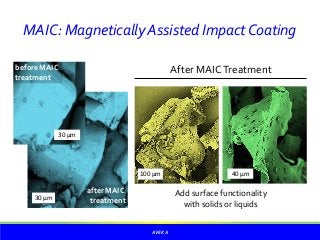

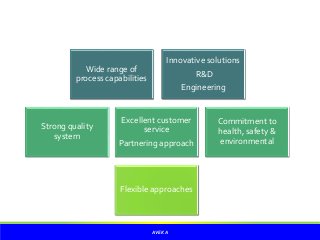

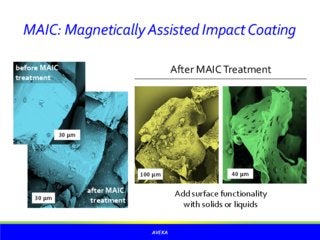

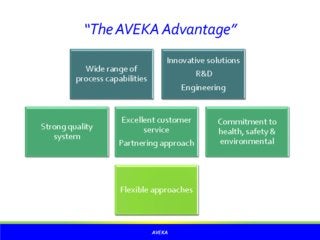

Aveka Group is a particle technology company focused on contract manufacturing and innovative solutions, having originated as a spin-off of 3M in 1994. The company offers diverse services including particle drying, encapsulation, and characterization, and operates multiple facilities across Iowa and Minnesota. It emphasizes a commitment to quality, R&D, and customer service while addressing challenges in particle processing and developing proprietary technologies.