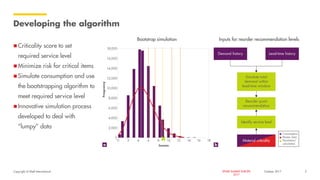

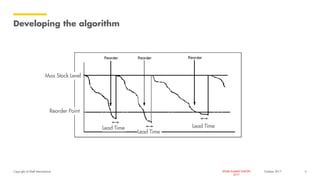

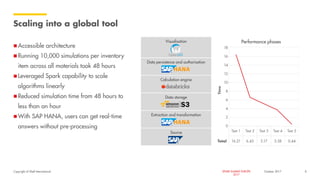

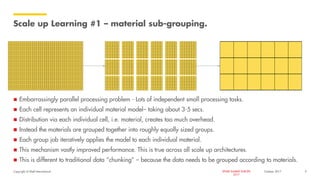

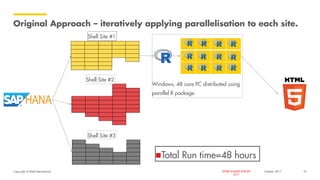

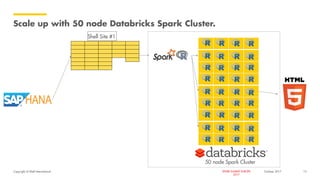

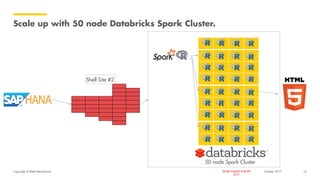

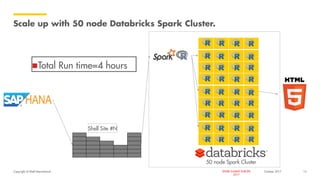

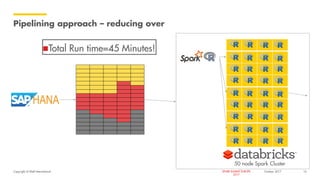

The document outlines Shell's advancements in optimizing spare part inventory through advanced analytics, highlighting challenges in materials management, user confidence, and algorithm development. A pilot project in the Gulf of Mexico demonstrated significant cost savings and efficiency improvements, including reducing simulation times dramatically via upgraded computing methods. The initiative is set to scale globally, with potential for extensive benefits across Shell's operations.