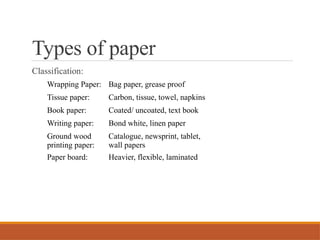

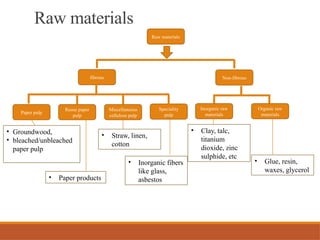

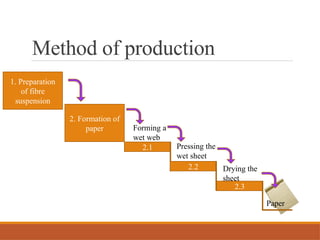

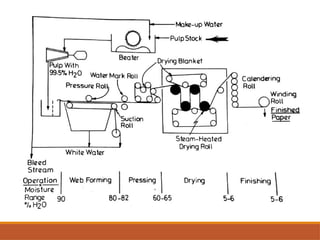

The document outlines the definition, classification, production methods, and global trends in the paper industry. It details the processes involved in creating paper from fiber suspension to the drying phase, while also discussing the challenges and growth opportunities in the context of declining graphic paper demand and rising packaging needs. The authors highlight the potential of digital manufacturing technologies for optimizing production in response to changing market demands.