The document describes ifm's product catalog for 2015/2016, including innovations in various sensor technologies. It provides details on 3D smart sensors, industrial imaging sensors, photoelectric sensors, position sensors, magnetic sensors, laser sensors, encoders, flow sensors, level sensors, pressure sensors, temperature sensors, process sensors, identification systems, vibration monitoring systems, connection technology, and software. The catalog highlights new products, technologies, and features across ifm's range of sensors and systems.

![7

(11.2015)

Inductive sensors

Position sensors

Dimensions

Example IFS290

Example IFS285

Example IGS280

Example IFS277

Example IIS269

Example IIS268

Sensing range

[mm]

Current rating

[mA]

Switching

frequency

[Hz]

Order

number

M12 connector · 3 wire DC PNP · Output function normally open

45 4 1002000 IFS289M12

M12

M12

M12

M18

M18

45 10 1002000 IFS290

60 4 1002000 IFS285

60 10

Installation

flush

non-flush

flush

non-flush 1002000 IFS286

45 8 1002000 IGS279

45 15 1002000 IGS280

flush

non-flush

M18

M18

60 8 1002000 IGS277

60 15 1002000 IGS278

flush

non-flush

M30

M30

45 15 1002000 IIS269

60 15 1002000 IIS267

flush

flush

M30 60 30 1002000 IIS268non-flush

Type Total length

[mm]

Operating voltage [V DC] 10...30

Reverse polarity protection •

Short-circuit protection •

Overload protection •

Protection rating

IP 65 / IP 66 / IP 67 /

IP 68 / IP 69K

Protection class III

Ambient temperature [°C] -40...85

Output status indication [LED] yellow (4 x 90°)

Further technical data

Connection technology

Type Version Order

number

Socket, M12,

2 m black, PUR cable

EVC001

Socket, M12,

5 m black, PUR cable

EVC002

Socket, M12,

2 m black, PUR cable

EVC004

Socket, M12,

5 m black, PUR cable

EVC005

For further technical details please visit: www.ifm.com

Housing materials

brass

plated with white bronze,

sensing face

LCP

34

25

M12x1

17

4

M12x1

45

LED 4 x 90°

5

49

45

M12x1

M12x1

60

LED 4 x 90° 17

4

LED 4 x 90°

45

34

30

1015

M12x1

4

M18x1

24

M18x1

M12x1

45

49

60

LED 4 x 90° 24

4

45

M30x1,5

49

60

M12x1

LED 4 x 90° 5

36

45

49

60

22,5

M30x1,5

M12x1

LED 4 x 90°

5

36](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-8-320.jpg)

![9

(11.2015)

Inductive sensors

Position sensors

Dimensions

IFW204

IGW202

IIW202

Sensing range

[mm]

Current

load

[mA]

Switching

frequency

[Hz]

Order

number

M12 connector · 3 wire DC PNP · Output function normally open

65 4 1002000 IFW204M12

M18

M30

65 8 1002000 IGW202

65 15 1002000 IIW202

Installation

flush

flush

flush

Type Total length

[mm]

Operating voltage [V DC] 10...30

Current consumption [mA] < 20

Reverse polarity protection •

Short-circuit protection •

Overload protection •

Protection

IP 65 / IP 66 / IP 67 /

IP 68 / IP 69K

Protection class II

Ambient temperature [°C] -40...85

Housing materials

brass

anti-spatter,

sensing face LCP

Switching status indication [LED] yellow (4 x 90°)

Further technical data

Connection technology

Type Version Order

number

Socket, M12,

2 m grey, PUR cable

EVW001

Socket, M12,

5 m grey, PUR cable

EVW002

Socket, M12,

10 m grey, PUR cable

EVW003

Socket, M12,

2 m grey, PUR cable

EVW004

Socket, M12,

5 m grey, PUR cable

EVW005

Socket, M12,

10 m grey, PUR cable

EVW006

For further technical details please visit: www.ifm.com

Accessories

Type Version Order

number

M12 mounting sleeve with end stop,

anti-spatter

E12452

M18 mounting sleeve with end stop,

anti-spatter

E12453

M30 mounting sleeve with end stop,

anti-spatter

E12454

M12 washers,

anti-spatter

E12412

M18 washers,

anti-spatter

E12413

M30 washers,

anti-spatter

E12414

65

54

50

M12x1

M12x1

17

4

LED 4 x 90°

65

50

24

4

54

LED 4 x 90°

M18x1

M12x1

65

50

54

M12x1

36

M30x1,5

5

LED 4 x 90°](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-10-320.jpg)

![11

(04.2015)

Operating voltage [V DC] 24 (12...30)

Current consumption [mA] 30

Ambient temperature [°C] -40...85

Common technical data

Capacitive sensors

Mounting options

The sensor can be installed in all housings with

a Ø 22.5 mm hole. The supplied lock nut is used

for fixing.

Thanks to the M22 thread the sensor can be used

for screw mounting without lock nut. Installation

alignment of the sensor is not necessary since the clip

showing the symbol for the sensing face is snapped

in as the last step.

Wiring is done via the tried-and-tested 3- or 4-wire

technology.

Position sensors

Connection Current rating

[mA]

Protection Order

no.

Output function NO · DC PNP

Housing material

dynamic

0.3 m PUR cable

with M12 plug

200IP 65, IP 67, IP 69K KT5102M22 PA

static

0.3 m PUR cable

with M12 plug

200IP 65, IP 67, IP 69K KT5106M22 PA

latching 2 m PUR cable 200IP 65, IP 67, IP 69K KT5150M22 PA

latching

0.3 m PUR cable

with M12 plug

200IP 65, IP 67, IP 69K KT5151M22 PA

latching 2 m PUR cable 200IP 65, IP 67, IP 69K KT5350M22 Stainless steel

latching

0.3 m PUR cable

with M12 plug

200IP 65, IP 67, IP 69K KT5351M22 Stainless steel

Type Evaluation principle

Accessories

Socket, M12,

2 m black, PUR cable

EVC001

Socket, M12,

5 m black, PUR cable

EVC002

Socket, M12,

2 m black, PUR cable

EVC004

Socket, M12,

5 m black, PUR cable

EVC005

Symbol disc must be ordered separately

For further technical data please go to: www.ifm.com

Connection technology

Type Description Order

no.

Symbol disc,

lettering: START

E12377

Symbol disc,

lettering: STOP

E12378

Symbol disc,

symbol: on

E12379

Symbol disc,

symbol: off

E12380

Symbol disc,

transparent

E12386

Type Description Order

no.

Plastic housing,

24 V DC, 2.5 A

DN1031

Power supplies

Output function NO · DC PNP · LED can be controlled separately

Type Description Order

no.

static 2 m PUR cable 200IP 65, IP 67, IP 69K KT5110M22 PA

dynamic 2 m PUR cable 200IP 65, IP 67, IP 69K KT5111M22 PA

dynamic

0.3 m PUR cable

with M12 plug

200IP 65, IP 67, IP 69K KT5112M22 PA

dynamic 2 m PUR cable 200IP 65, IP 67, IP 69K KT5309M22 Stainless steel

static 2 m PUR cable 200IP 65, IP 67, IP 69K KT5310M22 Stainless steel](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-12-320.jpg)

![13

(04.2015)

M12x1

10

1527,8

4

17

M12x1

9,7

7,8

60

Magnetic sensors

Position sensors

For further technical details please visit: www.ifm.com

Connection technology

Type Description Order

no.

Socket, M12,

2 m black, PUR cable

EVC001

Socket, M12,

5 m black, PUR cable, LED

EVC008

Cable socket, M12, shielded, 120 °C

5 m black, PUR cable

E12339

Cable socket, M12, shielded, 120 °C

10 m black, PUR cable

E12340

Type Sensing

range

[mm]

Total length

[mm]

f

[Hz]

OutputAmbient

temperature

[°C]

Order

no.

Operating principle: magnetically biased

M12 1.8 f93 1000 PNP, normally open-25...120

M12 1.8 f93 1000 NPN, normally open-25...120

M12 1.8 f60 1000 PNP, normally open-25...120

M12 1.8 f60 1000 NPN, normally open-25...120

M12 1.8 f60 1000 PNP, normally closed-25...120

M14 1.8 f53 1000 PNP, normally open-25...85

Operating voltage [V] 10...36 DC

Current rating [mA] 200

Short-circuit protection,

pulsed

•

Reverse polarity /

overload protection

• / •

Protection rating,

protection class

IP 65 / IP 68 / IP 69K,

III

Connection M12 connector

Housing material

stainless steel

316L / 1.4404

Common technical data

Power supplies

Type Description Order

no.

Plastic housing,

24 V DC, 2.5 A

DN1031

Metal housing,

24 V DC, 3.3 A

DN4011

Dimensions

Example MFH202

L+

L

1

4

3

Wiring diagram

L+

L

1

2

3

Two designs for many different requirements

The MFH with its standard M12 housing can be installed

and adjusted on many different hydraulic cylinders.

That is why most cylinder types are covered by only one

sensor.

Due to its end stop the M9H allows quick mounting.

The processing / installation time is reduced if always

the same cylinder type is used.

MFH200

MFH201

MFH202

MFH203

MFH204

M9H200](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-14-320.jpg)

![15

(11.2015)

Infrared sensors / red light sensors

Position sensors

For further technical details please visit: www.ifm.com

Diffuse reflection sensor with background suppression · 3-wire DC

Spot

diameter

[mm]

Connection

M8 connector

8*

Range

[mm]

2...200 4-pole

Current

consumption

[mA]

22

Diffuse reflection sensor · 3-wire DC

15*5...500 4-pole 16

Retro-reflective sensor with polarisation filter · 3-wire DC

150**50...5000 4-pole 12

Through-beam sensor – transmitter · 2-wire DC

300*0...10000 4-pole 11

Through-beam sensor – receiver · 3-wire DC

–0...10000 4-pole 7

Type of light,

wave length

[nm]

Red light, 633

Red light, 633

Red light, 645

Red light, 645

Red light, 645

* at maximum range, ** referred to prismatic reflector Ø 80 mm

Accessories

Type Description Order

no.

Common technical data

Operating voltage [V DC] 10...30

Switching status indication LED Yellow

Operation LED Green

Short-circuit protection, pulsed •

Reverse polarity protection /

overload protection

• / •

Ambient temperature [°C] -25...60

Voltage drop [V] < 2.5

Current rating [mA] 100

Materials Housing

Lens

Seal

High-grade stainless steel

(316L/1.4404), PPSU

PMMA

FKM

Switching frequency [Hz] 1000

Protection rating,

protection class

IP 65, IP 67, IP 68, IP 69 K,

III

O6H400O6H401

Order

no.

Order

no.

PNPNPN

O6T400O6T401

PNPNPN

O6P400O6P401

PNPNPN

O6S400

O6E400O6E401

PNPNPN

Angle bracket for free-standing

mounting, stainless steel

E21271

Protective bracket,

stainless steel

E21273

Mounting accessories

Plastic housing,

24 V DC, 2.5 A

DN1031

Metal housing,

24 V DC, 3.3 A

DN4011

Power supplies

Connection technology

Type Description Order

no.

Socket, M8, 4-pole

2 m black, PUR cable

EVC150

Socket, M8, 4-pole

5 m black, PUR cable

EVC151

Socket, M8, 4-pole

2 m black, PUR cable

EVC153

Socket, M8, 4-pole

5 m black, PUR cable

EVC154

Ø 50 mm, plastic E20956

Ø 80 mm, plastic E20005

48 x 48 mm, PMMA, ABS E20744

95 x 95 mm, plastic E20454

Prismatic reflectors

Mounting set for clamp mounting,

stainless steel, Ø 10 mm

E21272

Mounting set for clamp mounting,

stainless steel, Ø 12 mm

E21275

Rod, 120 mm, Ø 10 mm,

M8 thread, stainless steel

E21081

Rod, 100 mm, Ø 12 mm,

M10 thread, stainless steel

E20938](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-16-320.jpg)

![17

(04.2015)

Infrared sensors / red light sensors

Diffuse reflection sensor · 3-wire DC

Light spot diameter

[mm]

Connection Order

no.

15* O6T215

Range

[mm]

5...600 mm

M8 connector,

4-pole

Order

no.

O6T216

Position sensors

PNPNPN

Through-beam sensor - transmitter · 2-wire DC

300*0...15 m

M8 connector,

4-pole

O6S215

Through-beam sensor – receiver · 3-wire DC

– O6E2150...15 m

M8 connector,

4-pole

O6E216

PNPNPN

* at maximum range

Light-on / dark-on mode

• / •

adjustable

– / –

• / •

adjustable

For further technical details please visit: www.ifm.com

Accessories

Type Description Order

no.

Mounting set for clamp mounting,

stainless steel, Ø 10 mm

E21272

Mounting set for clamp mounting,

stainless steel, Ø 12 mm

E21275

Angle bracket for free-standing

mounting, stainless steel

E21271

Protective bracket,

stainless steel

E21273

Rod, 120 mm, Ø 10 mm,

M8 thread, stainless steel

E21081

Rod, 100 mm, Ø 12 mm,

M10 thread, stainless steel

E20938

Cube for mounting on an aluminium

profile, M8 thread, diecast zinc

E20950

Cube for mounting on an aluminium

profile, M10 thread, diecast zinc

E20951

Mounting accessories

Common technical data

Operating voltage [V DC] 10...30

Type of light Infrared light 850 nm

Switching status indication LED Yellow

Switching frequency [Hz] 1000

Protection rating,

protection class

IP 65 / IP 67,

III

Indication stable operation LED Green

Short-circuit protection, pulsed •

Reverse polarity protection /

Overload protection

• / •

Ambient temperature [°C] -25...60

Voltage drop [V] < 2.5

Current rating [mA] 100

Materials Housing

Lens

ABS

PMMA

Connection technology

Type Description Order

no.

Socket, M8, 4-pole

2 m black, PUR cable

EVC150

Socket, M8, 4-pole

5 m black, PUR cable

EVC151

Socket, M8, 4-pole

2 m black, PUR cable

EVC153

Socket, M8, 4-pole

5 m black, PUR cable

EVC154

Plastic housing,

24 V DC, 2.5 A

DN1031

Metal housing,

24 V DC, 3.3 A

DN4011

Power supplies](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-18-320.jpg)

![19

(11.2014)

Infrared sensors / red light sensors

Position sensors

For further technical details please visit: www.ifm.com

Diffuse reflection sensor with background suppression · 3-wire DC · PNP

Light spot diameter

[mm]

Connection

M8 connector

Order

no.

8* O6H309

Range

[mm]

2...200 4-pole

Current

consumption

[mA]

22

Diffuse reflection sensor · 3-wire DC · PNP

15* O6T3095...500 4-pole 16

Retro-reflective sensor with polarisation filter · 3-wire DC · PNP

150** O6P30950...5000 4-pole 12

Through-beam sensor - transmitter · 2-wire DC

300*0...10000 4-pole 11 O6S305

Through-beam sensor – receiver · 3-wire DC · PNP

– O6E3090...10000 4-pole 7

Communication

interface

IO-Link 1.1

IO-Link 1.1

IO-Link 1.1

IO-Link 1.1

IO-Link 1.1

* at maximum range

** referred to prismatic reflector Ø 80 mm

Accessories

Type Description Order

no.

Mounting set for clamp mounting,

stainless steel, Ø 10 mm

E21272

Angle bracket for free-standing

mounting, stainless steel

E21271

Rod, 120 mm, Ø 10 mm,

M8 thread, stainless steel

E21081

Memory plug, parameter memory

for IO-Link sensors

E30398

IO-Link interface, current consumption

from USB port

E30396

LINERECORDER SENSOR,

software for parameter setting and

set-up of IO-Link sensors

QA0001

Common technical data

Operating voltage [V DC] 10...30

Type of light red light 633 nm

Switching status indication LED yellow

Operation LED green

Short-circuit protection, pulsed •

Reverse polarity protection /

overload protection

• / •

Ambient temperature [°C] -25...80

Voltage drop [V] < 2.5

Current rating [mA] 100

Materials housing

lens

high-grade stainless steel

(316L/1.4404), PPSU

PMMA

Connection technology

Type Description Order

no.

M8 socket, 4-pole,

2 m orange, PVC cable

M8 socket, 4-pole,

5 m orange, PVC cable

M8 socket, 4-pole,

2 m orange, PVC cable

M8 socket, 4-pole,

5 m orange, PVC cable

Adapter cable

M12 plug to M8 socket 4-pole,

0.3 m orange, PVC cable

EVT248

Switching frequency [Hz] 1000

Protection rating,

protection class

IP 65, IP 67, IP 68, IP 69K,

III

Light-on / dark-on mode adjustable

18 x 18 mm, Solidchem plastic E21267

56 x 38 mm, Solidchem plastic E21268

48 x 48 mm, Solidchem plastic E21269

96 x 96 mm, Solidchem plastic E21270

EVT134

EVT135

EVT138

EVT139](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-20-320.jpg)

![21

(11.2014)

For further technical data please go to: www.ifm.com

Laser sensors / distance measurement sensors

Common technical data

Operating voltage [V DC] 10...30

Dimensions [mm] 56 x 18,2 x 46,5

Type of light

visible laser light

650 nm

Extraneous light on the object [klx] max. 8

Switching status indication LED yellow

Operation LED green

Distance value

3-digit

alphanumeric

display

Protection rating,

protection class

IP 65,IP 67

III

Short-circuit protection, pulsed •

Reverse polarity protection /

overload protection

• / •

Ambient temperature [°C] -25...60

Current rating [mA] 2 x 100

Output function

OUT1: NO

OUT2: NC

Position sensors

Connection technology

Type Description Order

no.

Socket, M12,

2 m black, PUR cable

EVC001

Socket, M12,

5 m black, PUR cable

EVC002

Socket, M12,

2 m black, PUR cable

EVC004

Socket, M12,

5 m black, PUR cable

EVC005

Photoelectric distance sensor, laser protection class 1 · M12 connector, complementary

Material housing / plug adapter

front pane / LED window

bezel

operator interface

PA

PMMA

stainless steel

TPU

Accessories

Type Description Order

no.

Mounting bracket for rod,

complete set incl. clamp

E21083

Protective bracket for rod,

complete set incl. clamp

E21084

Bracket for free-standing mounting E21087

Dovetail clamp E21088

Rod, 100 mm, Ø 12 mm,

M10 thread, stainless steel

E20938

Cube for mounting on an aluminium

profile, M10 thread, diecast zinc

E20951

Measuring

range

[mm]

Background

suppression

[m]

Switching

frequency

[Hz]

Spot Ø at

max. range

[mm]

Current

consumption

[mA]

Order

no.

Unit of

measurement

Hysteresis

[%]

Memory plug,

parameter memory for IO-Link sensors

E30398

IO-Link interface,

current consumption from USB port

E30396

LINERECORDER SENSOR,

software for parameter setting

and set-up of IO-Link sensors

QA0001

* in case of max. range

Metal housing,

24 V DC, 3.3 A

DN4011

Power supplies

Type Description Order

no.

30...2000 ...20 11 < 5 < 75 O5D151

30...2000 ...20 O5D15011 < 5 < 75 cm

inch< 7.5*

< 7.5*

PNP](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-22-320.jpg)

![23

(11.2014)

For further technical data please go to: www.ifm.com

Laser sensors / distance measurement sensors

Common technical data

Operating voltage [V DC] 10...30

Dimensions M30 x 90 mm

Type of light

visible laser light

650 nm

Extraneous light on the object [klx] max. 8

Switching status indication LED yellow

Operation LED green

Switch point (setting) radial setting ring

Protection rating,

protection class

IP 65,IP 67

III

Short-circuit protection, pulsed •

Reverse polarity protection /

overload protection

• / •

Ambient temperature [°C] -25...60

Current rating [mA] 2 x 100

Output function

OUT1: NO

OUT2: NC

Position sensors

Connection technology

Type Description Order

no.

Socket, M12,

2 m black, PUR cable

EVC001

Socket, M12,

5 m black, PUR cable

EVC002

Socket, M12,

2 m black, PUR cable

EVC004

Socket, M12,

5 m black, PUR cable

EVC005

Photoelectric distance sensor, laser protection class 1 · M12 connector, complementary

Measuring

range

[mm]

Background

suppression

[m]

Switching

frequency

[Hz]

Spot Ø at

max. range

[mm]

Current

consumption

[mA]

Order

no.

Unit of

measurement

Hysteresis

[%]

Material housing

front pane

stainless steel,

PBT, PC, FPM

PMMA

Rod, 100 mm, Ø 12 mm,

M10 thread, stainless steel

E20938

Cube for mounting on an aluminium

profile, M10 thread, diecast zinc

E20951

Type Description Order

no.

Accessories

Angle bracket for type M30,

stainless steel

E10737

Mounting clamp for types M30, PTB E10077

Mounting set Ø 30.2 mm,

clamp mounting, aluminium profile

E20875

Mounting set Ø 30.2 mm,

clamp mounting

E20873

Mounting set Ø 30.2 mm, clamp

mounting, high-grade stainless steel

E20874

Mounting clamp,

with end stop for types M30, PC

E11049

Memory plug,

parameter memory for IO-Link sensors

E30398

IO-Link interface,

current consumption from USB port

E30396

LINERECORDER SENSOR,

software for parameter setting

and set-up of IO-Link sensors

QA0001

* in case of max. range

Metal housing,

24 V DC, 3.3 A

DN4011

Power supplies

Type Description Order

no.

30...2000 ...20 11 < 5 < 75 OID251

30...2000 ...20 OID25011

< 5*

< 5* < 5 < 75 cm / inch

cm

PNP](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-24-320.jpg)

![25

(04.2015)

Laser sensors / distance measurement sensors

Common technical data

Operating voltage [V DC] 10...30

Dimensions M30 x 70 mm

Type of light

Visible laser light

650 Nm,

can be switched off via

pin 5 or IO-Link

Extraneous light on the object [klx] Max. 8

Switching status indication LED Yellow

Switch point

(set)

via IO-Link 1.1

Protection rating,

protection class

IP 65, IP 67, IP 68, IP 69K

III

Short-circuit protection, pulsed •

Reverse polarity protection /

overload protection

• / •

Ambient temperature [°C] -25...60

Current rating [mA] 2 x 100

Output function

OUT1: NO

OUT2: NC

For further technical details please visit: www.ifm.com

Position sensors

Connection technology

Type Description Order

no.

Socket, M12, 5-pole,

2 m black, PUR cable

EVC073

Socket, M12, 5-pole,

5 m black, PUR cable

EVC074

Socket, M12, 5-pole,

5 m black, PVC cable

EVT013

Photoelectric distance sensor · M12 connector, complementary

Measuring

range

[mm]

Background

suppression

[m]

Switching

frequency

[Hz]

Spot Ø at

max. range

[mm]

Current

consumption

[mA]

Order

no.

30...2000 ...20 11 < 5 < 75 OID254

Laser

protection

class

30...2000 ...20 OID20411

Hysteresis

[%]

< 2.5...5*

< 1.5...3* < 5 < 75 2

1

Material Housing

Front pane

Stainless steel

PMMA

Cube for mounting on an aluminium

profile, M10 thread, diecast zinc

E20951

Type Description Order

no.

Accessories

Angle bracket for type M30,

stainless steel

E10737

Mounting clamp for types M30, PTB E10077

Mounting clamp, with end stop

for types M30, PC

E11049

Memory plug, parameter memory

for IO-Link sensors

E30398

IO-Link interface,

current consumption from USB port

E30396

LINERECORDER SENSOR,

software for parameter setting and

setting up IO-Link sensors

QA0001

* at max. range

PNP

Hysteresis

500 1000 1500 20000

0

25

50

75

100

125

150

175

200

y

x

2 b

1 b

2 a

1 a

x: Distance in [mm], y: Hysteresis in [mm]

1. Background black (6 % remission)

2. Background white (90 % remission)

Laser protection class 1

Laser protection class 2](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-26-320.jpg)

![27

(04.2015)

Encoders

For further technical details please visit: www.ifm.com

Sensors for motion control

Flange IO-LinkResolution

[pulse/revolution]

Order

no.

Hollow shaft with integrated stator coupling· 4-digit display · Integrated pulse evaluation

direct •max. 10,000 (adjustable) ROP52012

Operating voltage

[V DC]

4.5...30

Shaft Ø

[mm]

Solid shaft · 4-digit display · Integrated pulse evaluation

servo •max. 10,000 (adjustable) RUP5006 4.5...30

clamp flange •max. 10,000 (adjustable) RVP51010 4.5...30

Protection IP 65, IP 67

Connection

M12 connector

(rotatable)

Further technical data

58

58

58

Housing Ø

[mm]

Switching frequency [kHz] 300

Accessories

Type Description Order

no.

Spring disc coupling,

Ø 6 mm / 10 mm, die-cast zinc; PA

E60117

Spring disc coupling,

Ø 10 mm / 10 mm, die-cast zinc; PA

E60118

Flexible coupling with clamp connection,

Ø 6 mm / 10 mm, aluminium

E60066

Flexible coupling with clamp connection,

Ø 10 mm / 10 mm, aluminium

E60067

Flexible coupling with adjusting screws,

Ø 10 mm / 10 mm, aluminium

E60022

Flexible coupling with adjusting screws,

Ø 6 mm / 10 mm, aluminium

E60028

Measuring wheel,

Ø 159.15 mm / 10 mm, Hytrel TPE-E

E60110

Measuring wheel,

Ø 159.16 mm / 10 mm, aluminium, PU

E60076

Measuring wheel,

Ø 63.66 ± 0.1 mm / 10 mm, Hytrel TPE-E

E60138

Measuring wheel,

Ø 63.6 mm, 10 mm, aluminium

E60095

Measuring wheel,

Ø 63.66 ± 0.1 mm / 6 mm, aluminium

E60137

Measuring wheel,

Ø 63.6 mm, 6 mm, aluminium

E60006

Angle bracket for RUP design,

aluminium, black anodised

E60033

Angle bracket for RUP design,

aluminium, black anodised

E60035

Fastening clamp for

synchro flange, steel

E60041

Memory plug, parameter memory

for IO-Link sensors

E30398

LINERECORDER SENSOR,

Software for parameter setting and

set-up of IO-Link sensors

QA0001

Accessories

Type Description Order

no.

Connection technology

Type Description Order

no.

M12 socket, shielded,

5 m black , PUR cable, 8 poles

E12403

M12 socket, shielded,

10 m black , PUR cable, 8 poles

E12404

M12 socket, shielded,

2 m black , PUR cable, 8 poles

E12402

USB IO-Link master for parameter setting

and analysis of units

Supported communication protocols:

IO-Link (4.8, 38.4 and 230 Kbits/s)

E30390

Adapter cable for the connection

between USB IO-Link master E30390

and 4-pole / 8-pole encoder

E12432](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-28-320.jpg)

![29

(04.2015)

Encoders

For further technical details please visit: www.ifm.com

Accessories

Type Description Order

no.

Spring disc coupling,

Ø 6 mm / 10 mm, die-cast zinc; PA

E60117

Spring disc coupling,

Ø 10 mm / 10 mm, die-cast zinc; PA

E60118

Flexible coupling with clamp connection,

Ø 6 mm / 10 mm, aluminium

E60066

Flexible coupling with clamp connection,

Ø 10 mm / 10 mm, aluminium

E60067

Flexible coupling with adjusting screws,

Ø 10 mm / 10 mm, aluminium

E60022

Flexible coupling with adjusting screws,

Ø 6 mm / 10 mm, aluminium

E60028

Measuring wheel,

Ø 159.15 mm / 10 mm, Hytrel TPE-E

E60110

Measuring wheel,

Ø 159.16 mm / 10 mm, aluminium, PU

E60076

Measuring wheel,

Ø 63.66 ± 0.1 mm / 10 mm, Hytrel TPE-E

E60138

Measuring wheel,

Ø 63.6 mm, 10 mm, aluminium

E60095

Measuring wheel,

Ø 63.66 ± 0.1 mm / 6 mm, aluminium

E60137

Measuring wheel,

Ø 63.6 mm, 6 mm, aluminium

E60006

Sensors for motion control

Flange IO-LinkResolution

[pulse/revolution]

Order

no.

Hollow shaft with integrated stator coupling

direct •max. 10,000 (adjustable) RA31006

Connection

M12

direct •max. 10,000 (adjustable) RA35006 cable, 2 m

direct •max. 10,000 (adjustable) RO310012 M12

direct •max. 10,000 (adjustable) RO350012 cable, 2 m

Shaft Ø

[mm]

Solid shaft

universal •max. 10,000 (adjustable) RB31006 M12

universal •max. 10,000 (adjustable) RB35006 cable, 2 m

servo •max. 10,000 (adjustable) RU31006 M12

servo •max. 10,000 (adjustable) RU35006 cable, 2 m

clamp flange •max. 10,000 (adjustable) RV310010 M12

clamp flange •max. 10,000 (adjustable) RV350010

36.5

36.5

58

58

Housing Ø

[mm]

36.5

36.5

58

58

58

58 cable, 2 m

Angle bracket for RB and RU design,

aluminium, black anodised

E60033

Angle bracket for RV design,

aluminium, black anodised

E60035

Switching frequency [kHz] 300

Operating voltage [V DC] 4.5...30

Protection IP 65, IP 67

Further technical data

Memory plug, parameter memory

for IO-Link sensors

E30398

LINERECORDER SENSOR,

software for parameter setting and

set-up of IO-Link sensors

QA0001

Accessories

Type Description Order

no.Fastening clamp for

synchro flange, steel

E60041

USB IO-Link master for parameter setting

and analysis of units

Supported communication protocols:

IO-Link (4.8, 38.4 and 230 Kbits/s)

E30390

Connection technology

Type Description Order

no.

M12 socket, shielded,

5 m black, PUR cable, 5 poles

EVC545

M12 socket, shielded,

10 m black, PUR cable, 5 poles

EVC546

M12 socket, shielded,

2 m black, PUR cable, 5 poles

EVC544](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-30-320.jpg)

![31

(11.2015)

90

75

22

45

62

5,3

36

4,5

Operating voltage [V DC]

with:

Switching and current outputs

Voltage output

IO-Link connection

9.2...30

12...30

18...30

Reverse polarity protection •

Angular range

Absolute accuracy

Repeatability

Resolution

JN2200

±180°/± 90°

≤ ± 0.5°

≤ ± 0.1°

≤ ± 0.05°

JN2201

± 45°

≤ ± 0.1°

≤ ± 0.05°

≤ ± 0.01°

Ambient temperature [°C] -40...85

Temperature coefficient [°/K] ≤ ± 0.002

Protection rating

IP 65 / IP 67 / IP 68 /

IP 69K

Number of measurement axes

with inclination

2

Frequency range [Hz] 0.1...400

Measuring range [g] ± 2, ± 4, ± 8

2

0.5...50

± 2

Number of measurement axes

with vibration

3 –

Housing material

diecast zinc

nickel-plated

Connection

2 x

M12 connector

(4 poles; A-coded)

Technical data

JN2200, JN2201

Inclination sensors

Connection technology

Type Description Order

no.

Socket, M12,

2 m black, PUR cable

EVM039

Socket, M12,

10 m black, PUR cable

EVM041

Socket, M12,

2 m black, PUR cable

EVM036

Socket, M12,

10 m black, PUR cable

EVM038

Jumper, M12,

5 m black, PUR cable

EVC069

Jumper, M12,

5 m black, PUR cable

EVC059

Accessories

Description Order

no.

Dimensions

Type

For further technical details please visit: www.ifm.com

Sensors for motion control

The products

Description Order

no.

Angular range ± 180° / ± 90°,

IO-Link

JN2200

Angular range ± 45°,

IO-Link

JN2201

Type

Communication interface

IO-Link 1.1,

COM 2,

38.4 kbaud

LINERECORDER SENSOR

Software for parameter setting and

set-up of IO-Link sensors

QA0001

USB IO-Link master for parameter setting

and analysis of units

Supported communication protocols:

IO-Link (4.8, 38.4 and 230 kBit/s)

E30390

Memory plug, parameter memory

for IO-Link sensors

E30398](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-32-320.jpg)

![33

(11.2014)

Operating voltage [V DC] 9.2...30

Reverse polarity protection •

Angular range

Resolution

Repeatability

JN2100

JN2300

± 180°

0.05°

≤ ± 0.1°

JN2101

JN2301

± 45°

0.01°

≤ ± 0.05°

Ambient temperature [°C]

Temperature coefficient [°/K] ≤ ± 0.002°

Protection

IP 65 / IP 67 / IP 68 /

IP 69K

Data interface

CANopen

Device profile

CiA DSP-410 /

SAE J1939

Limit frequency inclination [Hz]

adjustable:

10, 5, 1, 0.5

Filter for [Hz]

vibration monitoring

0.1...1, 0.1...10, 1...10,

2...400, 10...400

Housing material

Diecast zinc

nickel-plated

Connection

2 x

M12 connector

Technical data

JN2100, JN2101,JN2300, JN2301

Inclination sensors

Connection technology

Type Description Order

no.

Socket, M12,

2 m black, PUR cable

EVM039

Socket, M12,

10 m black, PUR cable

EVM041

Socket, M12,

2 m black, PUR cable

EVM036

Socket, M12,

10 m black, PUR cable

EVM038

Accessories

Description Order

no.

Adapter cable for CAN devices with

M12 connector (5 pole)

EC2062

Dimensions

36

4,5

90

75

22

45

60

5,3

Flexible, precise, reliable

Since zero point, direction of counting and limit

frequency can be set for a stable output signal, the

sensors can be adapted precisely to your application.

Very low temperature drift across the whole tempera-

ture range provides unrivalled reliability.

Ideal for different applications

The sensors allow complete CAN integration

according to the CANopen communication profiles,

CiA DSP-410 and CiA DS-301 profiles.

They are connected via an M12 connector. The

terminating resistor can be enabled.

The sensors provide the signals either as perpendicular

angle, Euler angle or Gimbal angle.

Type

Sensors for motion control

For further technical details please visit: www.ifm.com

Jumper, M12,

5 m, black, PUR cable

EVC069

Jumper, M12,

5 m, black, PUR cable

EVC059

-40...85

Number of measurement axes

for inclination

2

Number of measurement axes

for vibration

3 –

The products

Description Order

no.

Angular range ± 180°,

CANopen

JN2100

Angular range ± 45°,

CANopen

JN2101

Angular range ± 180°,

SAE J1939

JN2300

Angular range ± 45°,

SAE J1939

JN2301

Type](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-34-320.jpg)

![35

(04.2015)

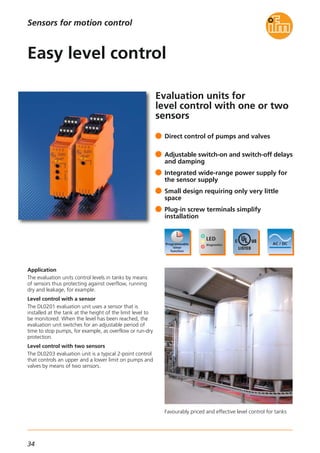

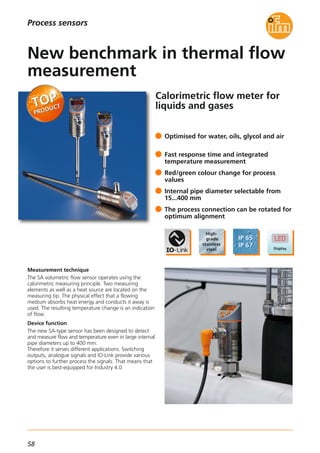

Further technical dataOperating principle DL0201

The DL0201 evaluation unit is actually a timer. When it

receives a signal from the connected sensor, it switches

the relay change-over contact for a certain period of

time. By means of two scaled potentiometers the user

can set the time between 0 and 60 seconds or 0 and

60 minutes. Adjustable switch-on and switch-off delays

act as damping. This suppresses brief fluctuations

around the sensor switch.

In addition the evaluation unit has an enable function

by means of which control can be bridged manually. A

leakage sensor can also be integrated into the control

function by means of the enable input.

Application example

The upper level in a tank is monitored via a capacitive

sensor. When the level has been reached, the sensor

provides a signal to the evaluation unit. It closes the

supply valve for the time set to prevent overfilling. The

damping function prevents, for example, one single

wave generating a switching signal.

Operating principle DL0203

It is a typical two-point control. When a sensor provides

a signal, the relay change-over contact switches until

the second sensor provides a signal for switch-off.

A switch-on delay is available that acts as damping and

suppresses short-term fluctuations around the sensor

switch point.

Application example

To protect a pump against running dry two capacitive

sensors are installed on the storage tank. When the

lower minimum level has been reached, the sensor

provides a signal to the evaluation unit. With the relay

output it switches off the pump that is normally used

to empty the tank.

When the upper level has been reached, the second

sensor installed there switches, the relay in the evaluation

unit switches on again and the pump is started.

Systems for pulse evaluation

Sensors for motion control

Nominal voltage

[V]

Outputs

Relays / transistors

Auxiliary energy

for sensors

Order

no.

Limit level monitoring (overflow, running dry, leakage)

110...240 AC

(50...60 Hz) / 27 DC

(typ. 24 DC)

1 / 1

typ. 18.5...30 V DC /

≤ 100 mA

short circuit /

overload protected

DL0201

Relay outputs

1 x changeover contact

4 A

(240 V AC, 24 V DC);

resistive load

Transistor outputs

1 x PNP /

externally supplied

10...30 V DC SELV /

≤ 100 mA

Ambient temperature [°C] -25...60

Storage temperature [°C] -25...70

Protection

housing / terminals

IP 20 / IP 20

Connection

4-pole connector

with screw connection,

5.0 mm pitch

For further technical details please visit: www.ifm.com

Type Inputs

Signal / enable

Input

frequency

[Hz]

1 x PNP / 1 x PNP

(type 2

acc. to IEC 61131-2)

≤ 5

Two-point control of levels

110...240 AC

(50...60 Hz) / 27 DC

(typ. 24 DC)

1 / 1

typ. 18.5...30 V DC /

≤ 100 mA

short circuit /

overload protected

DL0203

2 x PNP / –

(type 2

acc. to IEC 61131-2)

≤ 5

Display DL0201 LED

Power supply

Input

Output

Enable

Green

Yellow

Green (lights if

relay energised

and transistor

switched)

Green (lights if

enable signal is present)

Display DL0203 LED

Power supply

Input

Output

Green

2 x yellow

Green (lights if

relay energised

and transistor

switched)

Accessories

Type Description Order

no.

Connector,

4 poles with screw terminals,

pack of 5

(supplied)

E40173

Connector,

4 poles with cage clamps,

pack of 5

E40171](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-36-320.jpg)

![37

(04.2015)

25,4 109,1

93

LEDs

3

2

4

35,5

112,6

1

Sensors for motion control

For further technical details please visit: www.ifm.com

Systems for pulse evaluation

Dimensions

DN0220

1) plug-in screw terminals

2) panel for labelling

3) potentiometer

4) DIN rail mounting

Type Ub

[V]

Pulse

input

Inputs Auxiliary energy

for sensors

Input

frequency

[Hz]

Order

no.

Application: power supply and signal evaluation (e.g. for sensors)

110...240 AC

50...60 Hz

PNP / NPN1

24 V DC,

300 mA

≤ 10 DN0210

110...240 AC

50...60 Hz

PNP / NPN2

24 V DC,

2 x 150 mA

≤ 10

Outputs

Relay

1

2 DN0220

Relay output

Contact rating [A]

4 (240 V AC, 24 V DC);

resistive load

Auxiliary energy for sensors [V]

24 DC SELV, ± 10 %,

300 mA,

short-circuit and

overload protected

Protection

housing / terminals

IP 20 / IP 20

Ambient temperature [°C] -20...60

Display DN0210 LED

Power supply

Output

Fault

1 x green

1 x yellow (lights,

if output relay

is energised)

1 x red

Display DN0220 LED

Power supply

Output

Fault

1 x green

2 x yellow (light,

if output relay

is energised)

1 x red

Potentiometer

Selection

PNP / NPN

Housing material

Plastic:

PC GF20

Mounting

Rail TH35

(according to EN 60715)

Connection

Unit:

4-pole terminal blocks

with 5.0 mm pitch;

Connector:

4 poles with

screw connection

Further technical data

Setting range:

selectable for PNP and NPN switching sensors

Wiring diagram

Accessories

Type Description Order

no.

Connector,

4 poles with screw terminals,

pack of 5

(supplied)

E40173

Connector,

4 poles with cage clamps,

pack of 5

E40171

Power

21 22 23 24

AC

L L N N

In

12

9 Sensor

supply

10 pnp/npn

Out7

6

5

8

Power

21 22 23 24

AC

L L N N

In

2

16

13 Sensor

supply

14 pnp/npn

In

1

12

9 Sensor

supply

10 pnp/npn

Out

2

19

18

17

20

Out

1

7

6

5

8

DN0210 (1-channel) DN0220 (2-channel)](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-38-320.jpg)

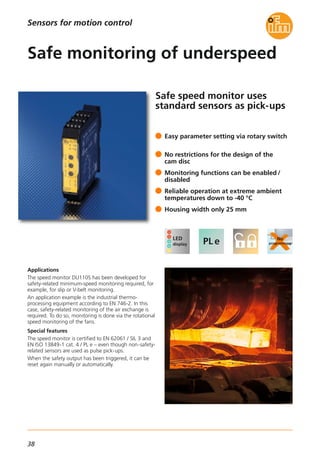

![39

(04.2015)

Easy setting of the limit speed

The speed is determined via the interval measurement

on the inputs where for example two inductive sensors

are used as pulse pick-ups.

The user can set the limit speed easily and effectively

via three rotary switches (x 1, x 10, multiplier) – either

in rpm or Hz. It was decided not to use any complicated

setting menus.

An easy and intuitive setting algorithm prevents

unintentional change or manipulation of the set values.

More functions

Automatic or manual reset of underspeed is possible.

This function is set via wire links.

The monitoring function can be enabled and disabled

via a switching input.

Besides the 2-pole safety relay, transistor outputs can

also be used as output for the status and error indication.

For further technical details please visit: www.ifm.com

Dimensions

22,5

99

108

1

LED

2

114,5

3

35,5

Systems for pulse evaluation

Sensors for motion control

1) Screw terminals

2) Rotary switch

3) DIN rail mounting

Wiring diagram

L- L+ S33 S34 S35 S44 S43 S45 13 23

(GND) (GND)

Y3 Y4 Y2 Y1 Y5 Y6 Y7 Y8 14 24

VCC = 24 V DC

24 V DC

Sensor 2Sensor 1

K1

K2K1

K2

Enable 1

Enable 2

Fault Overspeed

24 VRestart

Accessories

Type Description Order

no.

Plastic housing,

24 V DC, 2.5 A

DN1031

Metal housing,

24 V DC, 3.3 A

DN4011

Power supplies

Safety speed monitor

DU110S

Evaluation system for safe speed monitoring

Operating voltage [V DC]

19.2...28.8;

incl. 5 %

residual ripple

Nominal voltage [V DC] 24

Current consumption [mA] ≤ 125

Sensor supply 24 V DC / ≤ 70 mA

Protection IP 20 / II

Input characteristics

Pulse inputs

S34, S43:

“1”: 6 mA / 24 V DC

Adjustable speed range [rpm] 10...49500

Adjustable frequency range [Hz] 0.1...990

Input frequency [Hz] ≤ 5000

Output function

2 safety-related switching

outputs (floating contacts)

1 fault output “Fault”

(positive switching)

1 diagnostic output

“Overspeed”

(positive switching)

Output characteristics

Fault output “Fault” Y7

and diagnostic output

“Overspeed” Y8

≤ 20 mA, 24 V DC,

voltage drop ≤ 2 V DC,

short-circuit proof,

non safe

Contact rating

6 A,

250 V AC / 24 V DC

(≥ 6 mA);

resistive load

Ambient temperature [°C] -40...55

Storage temperature [°C] -40...75

Max. permissible relative [%]

humidity

95,

non condensing

Housing materials

PA

(polyamide)

Mounting

Rail TH35

(according to EN 60715)

Connection

Screw terminals;

0.5...2.5 mm²

(AWG 12...30)

Technical data](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-40-320.jpg)

![41

(11.2014)

Camera systems for

mobile machines

Description Order

no.

IR system illumination unit (850 nm) for mobile

3D sensors

O3M950

Further technical data

Smart sensor O3M151

Accessories

Housing material diecast aluminium

Device connection M12 connector

Protection rating,

protection class

IP 67 / IP 69K,

III

Operating voltage [V DC] 9...32

Functions and advantages

Powerful 3D time-of-flight measurement (ToF)

The principle of this 3D sensor is based on ifm’s patented

and award-winning pmd technology. It was specifically

designed for outdoor use and difficult ambient light

situations. Even interference such as sunlight or materials

with different reflective characteristics do not influence

the repeatability of the measured data.

Powerful electronics

The integrated 2 x 32-bit processor architecture ensures

a rapid and reliable calculation of the 3D data and

functions directly integrated in the system with up to

50 fps. The complete electronics of the mobile 3D smart

sensor is optimised and adapted to the demands and

requirements of mobile machines.

Besides shock and vibration resistance self-diagnostic

functions from the sensor to the IR system illumination

unit are of course also available.

Smart functions

The mobile 3D smart sensor integrates some functions

which enable to solve a multitude of applications.

A highly developed algorithm from the automotive

industry is used ensuring, for example, reliable automatic

object recognition of up to 20 objects. This function

can, for example, be used as collision warning.

For simple distance tasks typical functions such as

minimum / maximum / average distance are available.

System parameter setting and monitoring

The parameter setting of the system and live monitoring

of the 3D data are carried out via the easy-to-use ifm

vision wizard for Windows. As an alternative, parameter

setting can also be carried out via function blocks using

the software CODESYS.

Communication interfaces

The preprocessed function data is output via the CAN

bus using CANopen or SAE J 1939. If needed, the

complete 3D information can be processed at the same

time via Ethernet UDP and an external process unit.

Current consumption sensor [mA] < 400

Current consumption [A]

system illumination unit

< 5

Ambient temperature [°C] -40...85

Interfaces

1x CAN,

1 x fast Ethernet

Supported CAN protocols

CANopen,

SAE J 1939

Standards and tests

(extract)

CE,

E1 (UN-ECE R10)

For further technical details please visit: www.ifm.com

Industrial imaging

CAN/RS232 USB interface CANfox EC2112

Adapter cable set for CANfox EC2114

Operating software for vision sensors E3D300

U-shaped holder,

suitable for sensor or illumination unit

E3M100

Mounting set for clamp mounting,

Ø 14mm, stainless steel

E3M103

Connection technology

MCI cable, connection

sensor / system illumination unit, 1 m

E3M121

MCI cable, connection

sensor / system illumination unit, 2 m

E3M122

Type Description Order

no.

M12 socket, voltage supply system

illumination unit, 2 m,

PUR cable, 4 poles

E3M131

M12 socket, voltage supply system

illumination unit, 10 m,

PUR cable, 4 poles

E3M133

Ethernet, cross-over patch cable,

2 m, PVC cable, M12 / RJ45

E11898

Ethernet, cross-over patch cable,

10 m, PVC cable, M12 / RJ45

E12204

Type of sensor Resolution

pixels

[pixel]

IlluminationAngle of aperture

horizontal x vertical

[°]

Order

no.

PMD 3D sensor · Type O3M · M12 connector

PMD 3D chip 64 x 16

ext. illumination

required

70 x 23 O3M151

Max.

sampling rate

[Hz]

25/33/50](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-42-320.jpg)

![43

(11.2014)

Camera systems for

mobile machines

Further technical data

O3M150

Housing material diecast aluminium

Device connection M12 connector

Protection rating,

protection class

IP 67 / IP 69K,

III

Operating voltage [V DC] 9...32

Functions and advantages

Powerful 3D time-of-flight measurement (ToF)

The principle of this 3D sensor is based on ifm’s patented

and award-winning pmd technology. It was specifically

designed for outdoor use and difficult ambient light

situations. Interference such as sunlight or materials

with different reflective characteristics which occurs in

the area of mobile machines does not influence the

repeatability of the measured data.

Powerful electronics

The integrated 2 x 32-bit processor architecture ensures

a rapid and reliable calculation of the distance image to

be output with up to 50 fps. The complete electronics

of the mobile 3D sensor is optimised and adapted to the

demands and requirements of mobile machines.

Besides shock and vibration resistance self-diagnostic

functions from the sensor to the IR system illumination

unit are of course also available.

High system uptime

The system has various features to ensure uninterrupted

operation. They include, among others, a temperature-

controlled front lens heating, soiling indication as well

as different status information which can be fetched

from CAN.

System parameter setting and monitoring

The parameter setting of the system and live monitoring

of the 3D data are carried out via the easy-to-use ifm

vision wizard for Windows. As an alternative, parameter

setting can also be carried out via function blocks using

the software CODESYS.

Communication interfaces

The mobile 3D sensor features a fast Ethernet interface

(100 Mbit) as well as a CAN interface. The data output

of the complete 3D information is carried out via

Ethernet UDP and can be processed using a process

unit at the customer’s end. For this version the CAN in-

terface is only intended for parameter setting and

status output.

Current consumption sensor [mA] < 400

Current consumption [A]

system illumination unit

< 5

Ambient temperature [°C] -40...85

Interfaces

1x CAN,

1 x fast Ethernet

Supported CAN protocols

CANopen,

SAE J 1939

Standards and tests

(extract)

CE,

E1 (UN-ECE R10)

For further technical details please visit: www.ifm.com

Industrial imaging

Description Order

no.

IR system illumination unit (850 nm) for mobile

3D sensors

O3M950

Accessories

CAN/RS232 USB interface CANfox EC2112

Adapter cable set for CANfox EC2114

Operating software for vision sensors E3D300

U-shaped bracket,

suitable for sensor or illumination unit

E3M100

Mounting set for clamp mounting,

Ø 14mm, stainless steel

E3M103

Connection technology

MCI cable, connection

sensor / system illumination unit, 1 m

E3M121

MCI cable, connection

sensor / system illumination unit, 2 m

E3M122

Type Description Order

no.

M12 socket, voltage supply system

illumination unit, 2 m,

PUR cable, 4 poles

E3M131

M12 socket, voltage supply system

illumination unit, 10 m,

PUR cable, 4 poles

E3M133

Ethernet, cross-over patch cable,

2 m, PVC cable, M12 / RJ45

E11898

Ethernet, cross-over patch cable,

10 m, PVC cable, M12 / RJ45

E12204

Type of sensor Resolution

pixels

[pixel]

IlluminationAngle of aperture

horizontal x vertical

[°]

Order

no.

PMD 3D sensor · Type O3M · M12 connector

PMD 3D chip 64 x 16

ext. illumination

required

70 x 23 O3M150

Max.

sampling rate

[Hz]

25/33/50](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-44-320.jpg)

![45

(11.2015)

3D sensors

Mounting set for O3D E3D301

Further technical data

Accessories

Operating voltage [V DC] 20.4...28.8

Current consumption [mA]

< 2400 peak current

pulsed;

typ. mean value

420

Current rating [mA]

(per switching output)

100

Real chip resolution

25,000 /

100,000

Resulting resolution

176 x 132

pixels

Function display LED

2 x yellow,

2 x green

Illumination

850 nm,

infrared

Ambient light [lux]

Max. 10,000

(indoor)

Trigger

External;

24 V PNP/NPN

according to

IEC 61131-2 type 3

Switching inputs

2

(configurable),

24 V PNP/NPN

according to

IEC 61131-2 type 3

Switching outputs

3

(configurable),

24 V PNP/NPN,

according to

IEC 61131-2

Ambient temperature [°C] -10...50

For further technical details please visit: www.ifm.com

Industrial imaging

Connection technology

Type Description Order

no.

Ethernet, cross-over patch cable,

2 m, PVC cable, M12 / RJ45

E11898

Ethernet jumper,

2 m, PVC cable, M12 / M12

E21138

Type of sensor Material

front pane /

LED window

Angle of aperture

[°]

Protection rating,

protection class

Order

no.

PMD 3D sensors · Type O3D · M12 connector

PMD 3D ToF chip

Gorilla glass /

polyamide

Material

housing

Aluminium 40 x 30

IP 65 / IP 67,

III

O3D300

Max.

field of view size

[m]

2.61 x 3.47

PMD 3D ToF chip

Gorilla glass /

polyamide

Aluminium 60 x 45

IP 65 / IP 67,

III

O3D3023.75 x 5.00

PMD 3D ToF chip

Polycarbonate /

polyamide

Stainless steel 40 x 30

IP 66 / IP 67,

III

O3D3102.61 x 3.47

PMD 3D ToF chip

Polycarbonate /

polyamide

Stainless steel 60 x 45

IP 66 / IP 67,

III

O3D3123.75 x 5.00

Socket, M12,

2 m black, PUR cable, 8 poles

E11950

Type Description Order

no.

Short-circuit protection, pulsed •

Overload protection •

Parameter setting interface

Ethernet

10 Base-T /100 Base-TX

Possible parameter settings

Via PC /

notebook

Dimensions (H, W, D) [mm] 72 x 65 x 85

Technical data

Completeness monitoring

Operating distance [m] 0.3...5

Max. handling unit size 64 objects

Sampling rate / [Hz]

switching frequency

The image repetition frequency is

reduced by using the position tracking

function

10

Minimum size of objects [mm]

Object speed: 0...0.2 m/s

Object speed: > 0.2 m/s

25

45](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-46-320.jpg)

![47

(11.2015)

3D sensors

Mounting set for O3D E3D301

Further technical data

Accessories

For further technical details please visit: www.ifm.com

Industrial imaging

Connection technology

Type Description Order

no.

Ethernet, cross-over patch cable,

2 m, PVC cable, M12 / RJ45

E11898

Ethernet jumper,

2 m, PVC cable, M12 / M12

E21138

Type of sensor Material

front pane /

LED window

Angle of aperture

[°]

Protection rating,

protection class

Order

no.

PMD 3D sensors · Type O3D · M12 connector

PMD 3D ToF chip

Gorilla glass /

polyamide

Material

housing

Aluminium 40 x 30

IP 65 / IP 67,

III

O3D300

Max.

field of view size

[m]

2.61 x 3.47

PMD 3D ToF chip

Gorilla glass /

polyamide

Aluminium 60 x 45

IP 65 / IP 67,

III

O3D3023.75 x 5.00

PMD 3D ToF chip

Polycarbonate /

polyamide

Stainless steel 40 x 30

IP 66 / IP 67,

III

O3D3102.61 x 3.47

PMD 3D ToF chip

Polycarbonate /

polyamide

Stainless steel 60 x 45

IP 66 / IP 67,

III

O3D3123.75 x 5.00

Socket, M12,

2 m black, PUR cable, 8 poles

E11950

Type Description Order

no.

Technical data

Dimensioning of the object

Operating distance [m] 0.3...5

Object type Rectangular

Min. object size [mm] 100 x 100 x 100

Typical accuracy [°]

for angle of rotation

± 1

Sampling rate / switching frequency [Hz] 1

Typical accuracy [mm]

for object position

± 5

Object speed [m/s] < 0.2

Typical accuracy [mm]

for object size

± 10

Operating voltage [V DC] 20.4...28.8

Current consumption [mA]

< 2400 peak current

pulsed;

typ. mean value

420

Current rating [mA]

(per switching output)

100

Real chip resolution

25,000 /

100,000

Resulting resolution

176 x 132

pixels

Function display LED

2 x yellow,

2 x green

Illumination

850 nm,

infrared

Ambient light [lux]

Max. 10,000

(indoor)

Trigger

External;

24 V PNP/NPN

according to

IEC 61131-2 type 3

Switching inputs

2

(configurable),

24 V PNP/NPN

according to

IEC 61131-2 type 3

Switching outputs

3

(configurable),

24 V PNP/NPN,

according to

IEC 61131-2

Ambient temperature [°C] -10...50

Short-circuit protection, pulsed •

Overload protection •

Parameter setting interface

Ethernet

10 Base-T /100 Base-TX

Possible parameter settings

Via PC /

notebook

Dimensions (H, W, D) [mm] 72 x 65 x 85](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-48-320.jpg)

![49

(11.2015)

3D cameras

Mounting set for O3D E3D301

Further technical dataAccessories

Operating voltage [V DC] 24

Current consumption [mA] < 1000 (max. 2500)

Current rating [mA]

(per switching output)

100

Range [m] Typically 5

Unambiguous range [m] 0...30

Sampling rate / [Hz]

switching frequency

Max. 20,

adjustable

Resolution

176 x 132

pixels

Function display LED

2 x yellow,

2 x green

Illumination

850 nm,

infrared

Ambient light [lux]

Max. 10,000

(indoor)

Trigger

Internal or external:

24 V PNP / NPN selectable,

according to

IEC 61131-2 type 2

Switching inputs

Max: 2 (configurable),

24 V PNP / NPN selectable,

according to

IEC 61131-2 type 2

Switching outputs

Max: 2 (configurable),

24 V PNP / NPN selectable

or 1 analogue output (con-

figurable) scalable, 4...20

mA according to

IEC 61131-2,

max. load 300 Ω,

0...10 V according to

IEC 61131-2,

min. load 10 kΩ

Ambient temperature [°C] -10...50

For further technical details please visit: www.ifm.com

Industrial imaging

Connection technology

Type Description Order

no.

Ethernet, cross-over patch cable,

2 m, PVC cable, M12 / RJ45

E11898

Ethernet jumper,

2 m, PVC cable, M12 / M12

E21138

PMD 3D camera · Type O3D · M12 connector

Socket, M12,

2 m black, PUR cable, 5 poles

EVC070

socket, M12,

5 m black, PUR cable, 5 poles

EVC071

Type Description Order

no.

Short-circuit protection •

Overload protection •

Parameter setting interface

Ethernet

10 Base-T /100 Base-TX

Possible parameter settings

Via PC /

notebook

Type of sensor Material

front pane /

LED window

Angle of

aperture

[°]

Protection rating,

protection class

Order

no.

Infineon® 3D

Image Sensor

Gorilla glass /

polyamide

Material

housing

Aluminium 40 x 30

IP65 / IP67,

III

O3D301

Max.

field of view size

[mm]

2.61 x 3.47

Infineon® 3D

Image Sensor

Gorilla glass /

polyamide

Aluminium 60 x 45

IP65 / IP67,

III

O3D3033.75 x 5.00

Infineon® 3D

Image Sensor

Polycarbonate /

polyamide

Stainless steel 40 x 30

IP66 / IP67,

III

O3D3112.61 x 3.47

Infineon® 3D

Image Sensor

Polycarbonate /

polyamide

Stainless steel 60 x 45

IP66 / IP67,

III

O3D3133.75 x 5.00](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-50-320.jpg)

![51

(11.2015)

Pressure sensors

Accessories

Type Description Order

no.

Operating voltage PT [V DC]

PU [V DC]

8...32

16...32

Common technical data

Medium temperature [°C] -40...125

Materials wetted parts 1.4542 (17-4 PH / 630)*

Protection IP 67 / IP 69K

Step response time [ms] 2

Restrictor •

EMC

Compliant with UN-ECE10

Rev. 4

ISO 11452: 100 V/m

EN61326

Reverse polarity protection •

Adapters; G 1/4 - G 1/2,

high-grade stainless steel (316Ti/1.4571)

E30135

For further technical details please visit: www.ifm.com

Process sensors

Measuring range

relative pressure

[bar]

Poverload

max.

[bar]

Pburst

min.

[bar]

Order

no.

Output function 0...10 V, DEUTSCH connector

0...10 25 300 PU5704

0...25 65 600 PU5703

0...100 250 1000 PU5702

0...250 625 1200 PU5701

0...400 1000 1700 PU5700

0...600 1500 2400 PU5760

Output function 0...10 V, AMP connector

0...10 300 PU5604

0...25 600 PU5603

0...100 1000 PU5602

0...250 1200 PU5601

0...400 1700 PU5600

0...600 2400 PU5660

Accuracy / deviation

(in % of the span)

Linearity error

Linearity

Hysteresis

Repeatability

Long-term stability

Temperature coefficients (TEMPCO)

in the temperature range 0 ... 80 °C

(in % of the span per 10 K)

TEMPCO of zero

TEMPCO of the span

Temperature coefficients (TEMPCO)

in the temperature ranges

-40...0 °C and 80...125 °C

(in % of the span per 10 K)

TEMPCO of zero

TEMPCO of the span

< ± 0.8

< ± 0.25 BFSL / < ± 0.5 LS

< ± 0.2

< ± 0.05

< ± 0.1

< ± 0.1

< ± 0.1

< ± 0.2

< ± 0.2

25

65

250

625

1000

1500

A

B

OUT

+L

Wiring diagram

1

3

L +

OUT

Dimensions

71,5

51,4

12

G 41

19

1

19

21,825,4

51,9

72

25,8

12

G 41

19

1

21,8

19

14,35

Type PT57/PU57

Type PT56/PU56

1) FKM seal / DIN 3869

Type PT56Type PT57

A

C

B

OUT

L -

L +L +

1

2

3

OUT

L +

L -

Type PU56Type PU57

Measuring range

relative pressure

[bar]

Poverload

max.

[bar]

Pburst

min.

[bar]

Order

no.

Output function 4…20 mA, DEUTSCH connector

0...10 25 300

0...25 65 600

0...100 250 1000

0...250 625 1200

0...400 1000 1700

0...600 1500 2400

Output function 4…20 mA, AMP connector

0...10 300

0...25 600

0...100 1000

0...250 1200

0...400 1700

0...600 2400

25

65

250

625

1000

1500

PT5704

PT5703

PT5702

PT5701

PT5700

PT5760

PT5604

PT5603

PT5602

PT5601

PT5600

PT5660

* Characteristics similar to stainless steel (e.g. 304/1.4301)

but higher strength](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-52-320.jpg)

![53

(04.2015)

Process sensors

For further technical details please visit: www.ifm.com

Pressure sensors

Splitter box *

with vent and terminal block

E30401

Additional weight, approx. 500 g E30402

Filter element * E30400

Cable fixing clamps * E30399

Submersible pressure transmitters with PUR cable for standard applications

0.6

0.6

0.6

4

4

4

1000 N

1000 N

1000 N

Measuring range

Relative pressure

[bar]

Approvals

CE / EX / GL

Overload pressure

[bar]

Pull force cable

1

1

5

5

1000 N

1000 N

Cable length

[m]

PS3407

PS3427

PS3607

Order

no.

PS3417

PS3617

0.25 2 1000 N

10

15

30

15

30

5

• / – / –

• / – / –

• / – / –

• / – / –

• / – / –

• / – / – PS3208

Operating voltage [V DC] 18...30

Analogue output [mA] 4...20

Accuracy / deviation

(in % of the span)

Accuracy (BFSL)

Accuracy incl. non-linearity

Non-linearity (BFSL)

Long-term stability per year

≤ 0.25 (PS3: 0.5)

≤ 0.5 (PS3: 1)

≤ 0.2

≤ 0.2

Design PS3

Ambient temperature / [°C]

Medium temperature

-10...50

Design PS4

Ambient temperature / [°C]

Medium temperature

-10...85

Design PS3

ATEX approval

Ambient temperature / [°C]

Medium temperature

1G, 1/2G, 2G:

T6 -10...60, T5: -10...80,

T4: -10...85

1D, 1/2D, 2D:

-10...40 (750 mW) / -

10...70 (650 mW) / -

10...85 (550 mW)

Housing material

High-grade stainless steel

(316Ti / 1.4571)

Further technical data

Accessories

Type Description Order

no.

* use only outside the hazardous area

Submersible pressure transmitters with FEP cable for high resistance to media

0.6

1

3

5

500 N

500 N

PS4407

PS4417

0.25 2 500 N

10

15

5

• / – / –

• / – / –

• / – / – PS4208

Submersible pressure transmitters with FEP cable for hazardous areas

0.6

1

4

5

500 N

500 N

PS307A

PS317A

0.25 2 500 N

10

15

5

• / • / •

• / • / •

• / • / • PS308A

Temperature coefficients (TEMPCO)

(in % of the span per 10 K)

Greatest TEMPCO of zero

Greatest TEMPCO of the span

≤ 0.2

≤ 0.2

100

27

Example PS3208

Dimensions](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-54-320.jpg)

![55

(04.2015)

Process sensors

For further technical details please visit: www.ifm.com

Pressure sensors

Accessories

Type Description Order

no.

Memory plug,

parameter memory for IO-Link sensors

E30398

IO-Link interface, current consumption

from USB port

E30396

Operating voltage [V DC] 18...30

Current rating [mA]

200

(up to 60 °C environment)

Accuracy / deviation

(in % of the span) turn down 1:1

Deviation of the switch point

Linearity error

Repeatability

Temperature coefficients (TEMPCO)

in the temperature range 0 ... 80 °C

(in % of the span per 10 K)

Greatest TEMPCO of zero

Greatest TEMPCO of the span

< ± 0.5 / (0.4 PN2)

< ± 0.25 (BFSL)

< ± 0.5 (LS)

< ± 0.1

< ± 0.2

< ± 0.2

Communication interface

IO-Link 1.1

COM2 slave;

38.4 kbaud

Medium temperature [°C] -25...80

Switching frequency [Hz] ≤ 170

Protection IP 67

Shock resistance [g] 50

Vibration resistance [g] 20

Type of pressure: relative pressure

Liquids and gases

Common technical data

Connection technology

Type Description Order

no.

Socket, M12,

2 m black, PUR cable

EVC004

Socket, M12,

5 m black, PUR cable

EVC005

Tag clip E30422

Damping screw, G 1/4 female E30419

Damping screw, G 1/4 male E30057

Protective cover, new generation E30420

Angle bracket, PA66 E30421

Siphon, G 1/4,

steel (1.0345)

E30140

LINERECORDER SENSOR,

software for parameter setting

and set-up of IO-Link sensors

QA0001

M12 connector

output function programmable

NO/NC

+ analogue:

4...20 mA/0...10 V

2 x NO/NC or

1 x NO/NC + 1 x analogue

(4...20 mA/0...10 V;

scalable)

0...400 bar

0...250 bar

0...100 bar

Ceramic-

capacitive

Measuring range

relative pressure

Order no.

G 1/4

male

Measuring cell

0...25 bar

-1...10 bar

0...2,5 bar

0...1000 mbar

-12,5...250 mbar

-1000...1000 mbar

Order no.

G 1/4

female

PN2570

PN2571

PN2592

Order no.

G 1/4

male

PN2593

PN2594

PN2596

PN2070

0...600 bar

Metal

(thin film)

PN2560PN2160

PN2071

PN2092

PN2093

PN2094

PN2096

PN2597

PN2598

PN2097

PN2098

PN2599PN2099

Order no.

G 1/4

female

PN7570

PN7571

PN7592

Order no.

G 1/4

male

PN7593

PN7594

PN7596

PN7070

PN7071

PN7092

PN7093

PN7094

PN7096

PN7597

–

PN7097

–

PN7599PN7099

-1000...0 mbar

-500...500 mbar

––

PN2569PN2169

––

––

Order no.

G 1/4

female

PN7560PN7160

PN3570

PN3571

PN3592

PN3593

PN3594

PN3596

PN3070

PN3560PN3160

PN3071

PN3092

PN3093

PN3094

PN3096

PN3597

–

PN3097

–

––

PN3529PN3129

––

2 x NO/NC](https://image.slidesharecdn.com/ifm-innovations-topproducts-2015-2016-gb-160202102146/85/Innovations-2015-2016-56-320.jpg)

![57

(11.2015)

IO-Link display

For further technical details please visit: www.ifm.com

Process sensors

Resolution

pixels

Display type Display

illumination

Order

no.

1.44“ colour display

128 x 128 TFT LED E30391

Wiring

Dimensions

Technical data

IO-Link display

E30391

Operating voltage [V DC] 18...30

Current consumption [mA] < 47

Protection rating /

protection class

IP 65, IP 67 /

III

Reverse polarity protection •

Ambient temperature [°C] 0...60

EMC

EN 61000-6-2

EN 61000-6-4

Shock resistance [g] 20 (11 ms)

Vibration resistance [g] 20 (10...50 Hz)

Housing materials

Stainless steel

(303/1.4305);

PC; PBT-GF 30;

PPS; PA 6.6; FKM