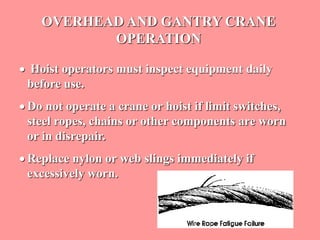

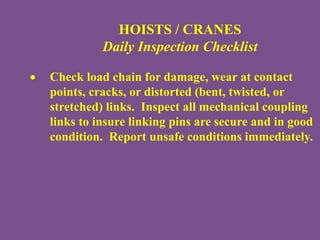

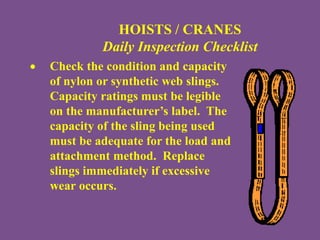

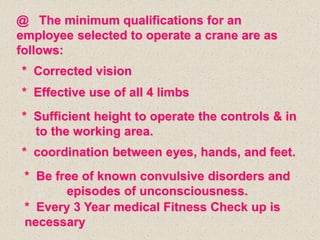

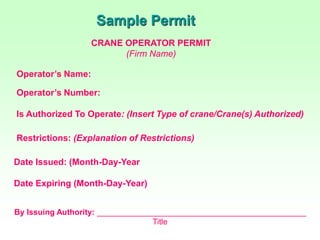

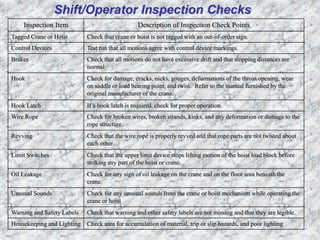

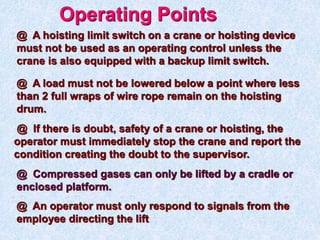

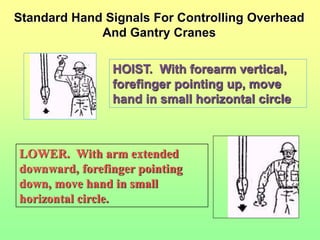

The document provides comprehensive guidelines for overhead crane operation, emphasizing safety, inspection, and maintenance requirements. It details daily inspection checklists, operating protocols, and necessary qualifications for operators, while also outlining specific practices for load handling and emergency procedures. Additionally, it stresses the importance of regular maintenance based on manufacturer recommendations and the implementation of preventive measures for safe crane operation.