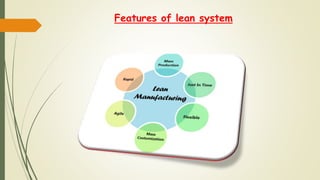

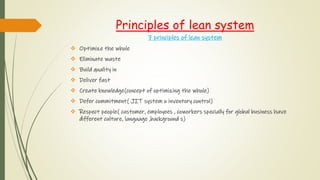

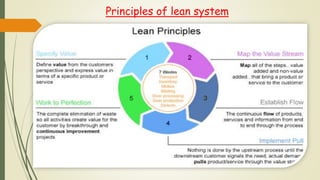

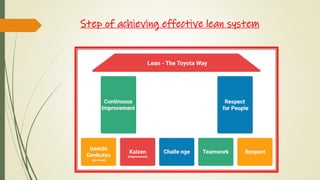

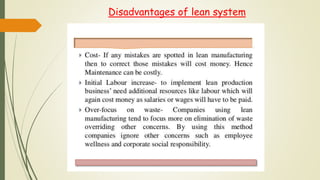

This document discusses operations management and lean systems. It defines a lean manufacturing system as one that provides a systematic method to reach operational efficiency by minimizing waste within manufacturing while maintaining productivity and quality. Lean systems were introduced in 1930 as the Toyota Production System. The document outlines 7 principles of lean systems: optimize the whole, eliminate waste, build quality in, deliver fast, create knowledge, defer commitment, and respect people. It also mentions tools and concepts like six sigma as well as advantages and disadvantages of lean systems.