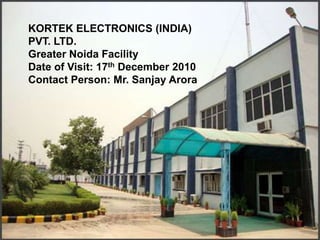

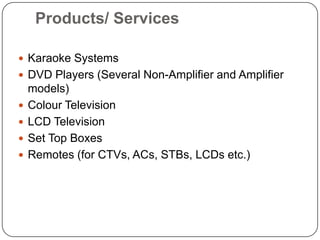

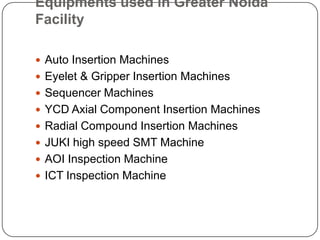

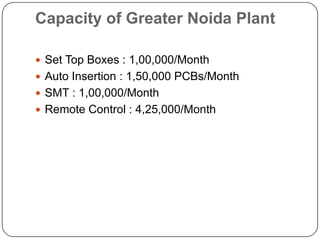

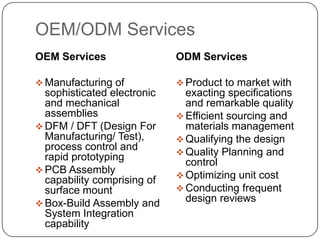

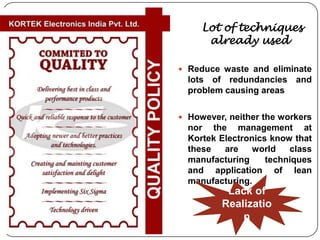

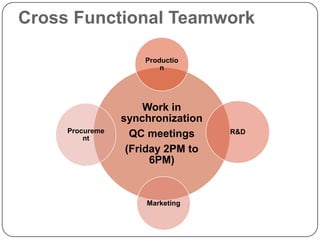

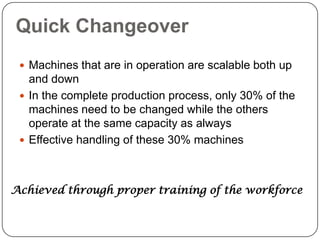

The document discusses KORTEK ELECTRONICS (INDIA) PVT. LTD., an electronics manufacturing company. It provides an overview of the company, its products and services which include karaoke systems, DVD players, televisions, set top boxes, and remotes. It describes the Greater Noida facility's manufacturing capacities and techniques used currently including auto insertion, SMT, and various inspection machines. It notes that some lean manufacturing techniques are already implemented but could be further improved and lists recommendations including goal deployment, benchmarking, and internal maintenance.