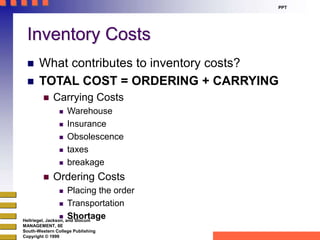

This document provides an overview of operations management concepts. It defines operations management as the systematic direction, control, and evaluation of processes that transform inputs into finished goods and services. It discusses the inputs, transformations, outputs, and performance feedback involved in operations management. The document also summarizes key concepts regarding quality, efficiency, responsiveness to customers, inventory management, and other operations management decisions.