This document summarizes a seminar presentation about Oil and Natural Gas Corporation Limited (ONGC).

[1] ONGC is India's largest crude oil and natural gas company, producing 69% of India's crude oil and 62% of its natural gas. It was established in 1956 and is headquartered in Dehradun, India.

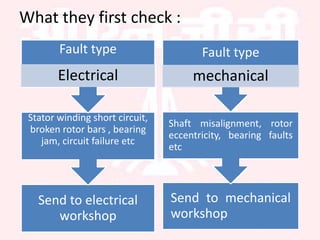

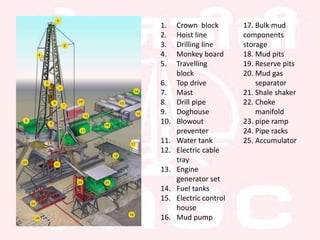

[2] The presentation covered an overview of ONGC, including its operations, maintenance processes, fault analysis, oil testing, welding transformers, and instruments used.

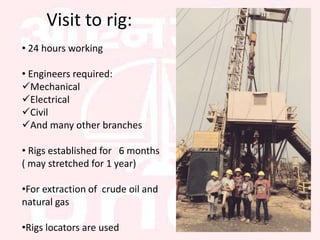

[3] It concluded with discussing a visit to an ONGC rig, thanking those involved for the learning experience, and highlighting what was learned about the complex operations involved in oil and gas