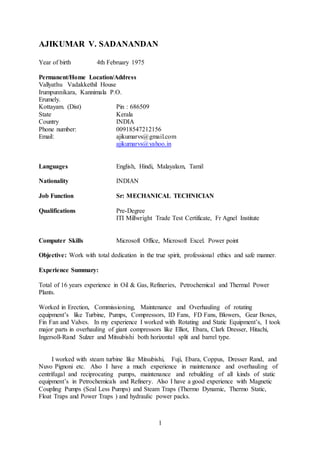

This document contains a resume for Ajikumar V. Sadanandan. It provides biographical information such as his name, date of birth, address, languages spoken, and qualifications. It then outlines his 16 years of experience working in maintenance and overhauling roles for rotating equipment like turbines, pumps, compressors, and valves at various oil, gas, refinery and petrochemical plants. It details his employment history from 2012 to 1994 at 12 different companies. His present responsibilities are described, including overhauling centrifugal pumps and compressors, maintenance of other equipment, and ensuring safety, quality and timely completion of jobs.

![3

Project Erection and Commissioning of 2x210mw Rotating

Machineries in Rayalaseema

Present job profile and main responsibilities

Static and Rotating Equipment.

Preparation of Spare parts

Before dismantling any equipment make sure all spare parts are available and recheck spare

parts material number with the Vendor drawing. Eg. ID, OD, thickness and material of O-

rings.

Overhauling and Maintenance of Single and Multi stage Centrifugal Pumps:

Before dismantling lock the Mechanical seal with spacer and unscrew the shaft sleeve allen

bolts. During dismantling and assembling check the alignment reading, axial float, shaft run

out, radial clearance of bearings and front impeller clearance with the help of dial indicator and

lead wire.

Inspect the condition of all rotating and stationary parts. Eg. Shaft, sleeve, wearing, bearings,

mechanical seal, impeller, oil rings, couplings, casing, stuffing box, bearing housing etc..

Assembly and dismantling of Balanced and Unbalanced Mechanical seal and Dry

Gas Seal

Maintenance of Gear pumps and Screw pumps.

Overhauling and Maintenance of Magnetic Coupling Pumps [Seal less pumps]

In magnetic coupling pumps the process liquid is working as the bearing lubricant. So the

inlet filtration is very important, otherwise the foreign particle will damage the bearing.

Start up and maintenance of single and multi stage Centrifugal Compressor

[Horizontal split and Barrel type]

Before dismantling lock the mechanical seal with spacer. Check and document the alignment

reading, rotor run out, end clearance and journal and thrust bearing clearance.

Use special tools for Rotor removal, taper hub removal and Diaphragm removal.

Inspect the condition of rotor, diaphragm, diffuser, journal and thrust bearings.

Overhauling and maintenance of Reciprocating compressor

Check the piston head clearance and piston radial clearance with lead wire and feeler gauge

and crank shaft web deflection with web deflection indicator. Replacement of piston rings,

rider rings, tension rings, rod pickings and adjust TDC & BDC. Replacement and repair of

compressor valves and perform seal lapping jobs.

Maintenance of Gas turbine and Steam turbine

Maintenance of Gear box

Inspect the Backlash with the help of dial indicator and teeth contact with precision blue.

Alignment jobs for various sectors

Checking and correcting the alignment by Rim and Face, Reverse Indicator method and Laser

alignment [Rotalign, Optalign and Optalign Plus]

Heat exchangers [Fixed tube, Floating head and U-tube type]

Coolers, Heaters, condensers, cooling tower and Reactors.

Re-boiler, vessels and Steam traps[Thermo dynamic, Thermo static, Float traps

and Power traps]

Maintenance and servicing of different types of valves.](https://image.slidesharecdn.com/12bbf46c-2708-4491-ba13-9ed03336ac74-150709083300-lva1-app6891/85/AJI-CV-3-320.jpg)