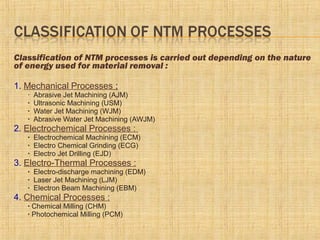

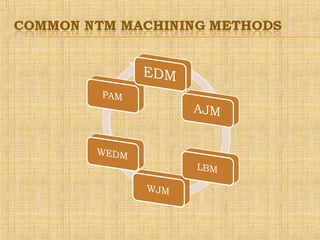

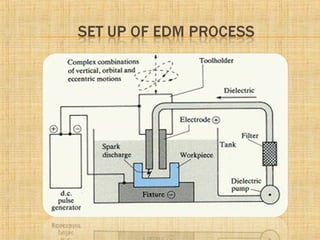

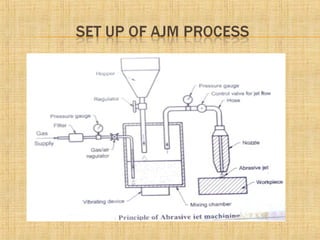

This document discusses non-traditional machining (NTM) processes. It defines NTM as processes that cut material using mechanical, thermal, electrical, or chemical energy without sharp cutting tools. NTM can machine extremely hard, brittle, or complex materials. The document classifies NTM into mechanical, electrochemical, electro-thermal, and chemical processes. It provides details on electrical discharge machining (EDM) and abrasive jet machining (AJM) processes, including their working principles, advantages, and disadvantages.