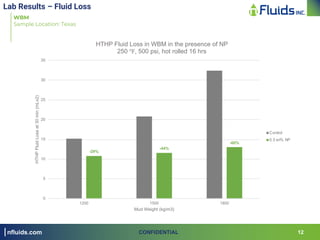

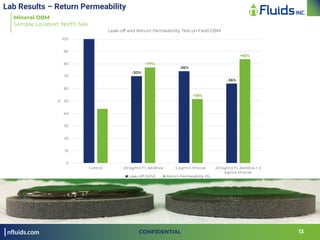

The document provides an overview of Nfluids Inc.'s nanotechnology solutions for oil and gas applications, focusing on drilling fluids and wellbore strengthening. It highlights the benefits of their proprietary nanomaterials, including improved filtration control, lubricity, and reduced oil on cuttings, supported by laboratory and field test results. Nfluids has developed multiple products, including the NFORCE™ additive, which enhances performance and environmental compatibility in drilling operations.