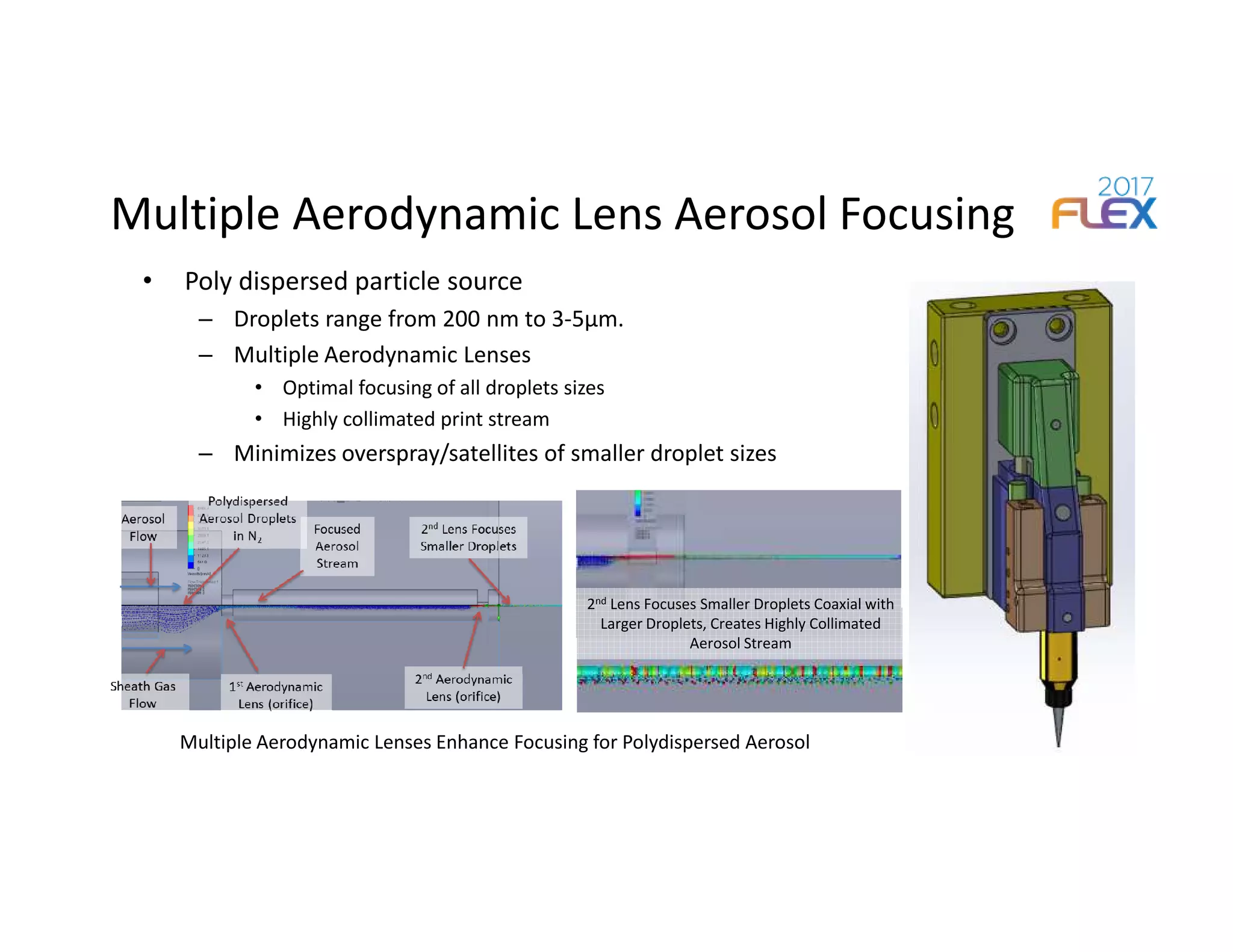

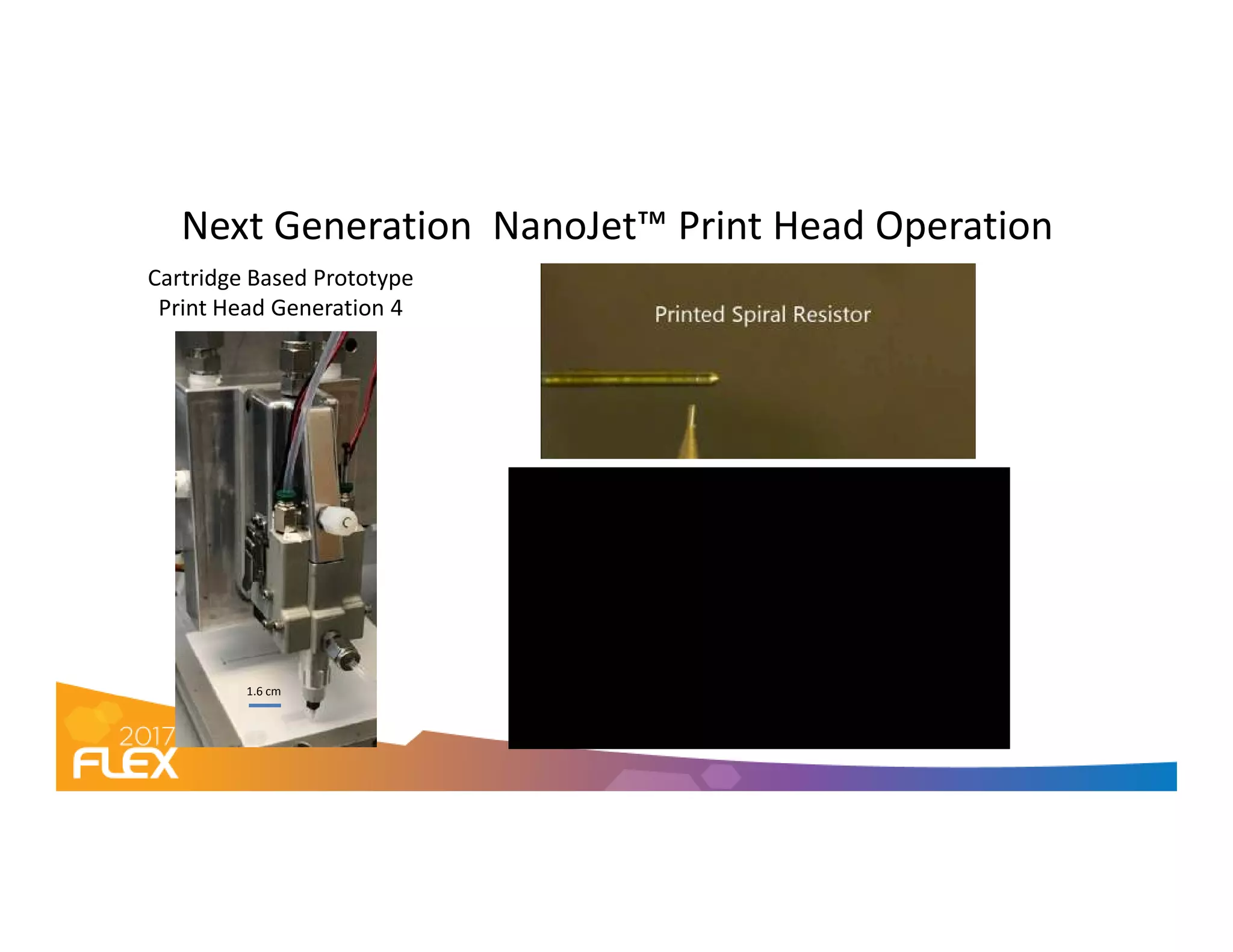

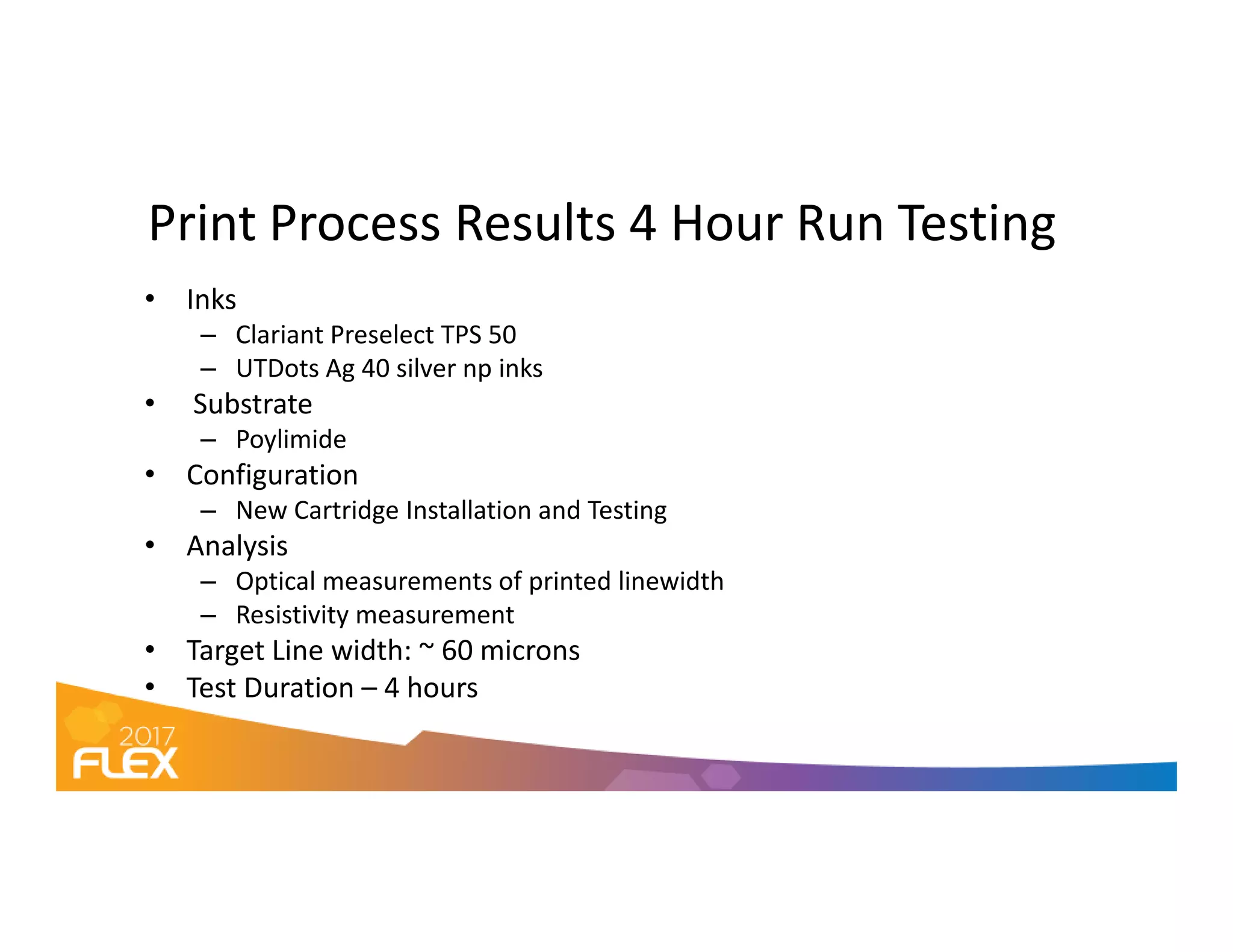

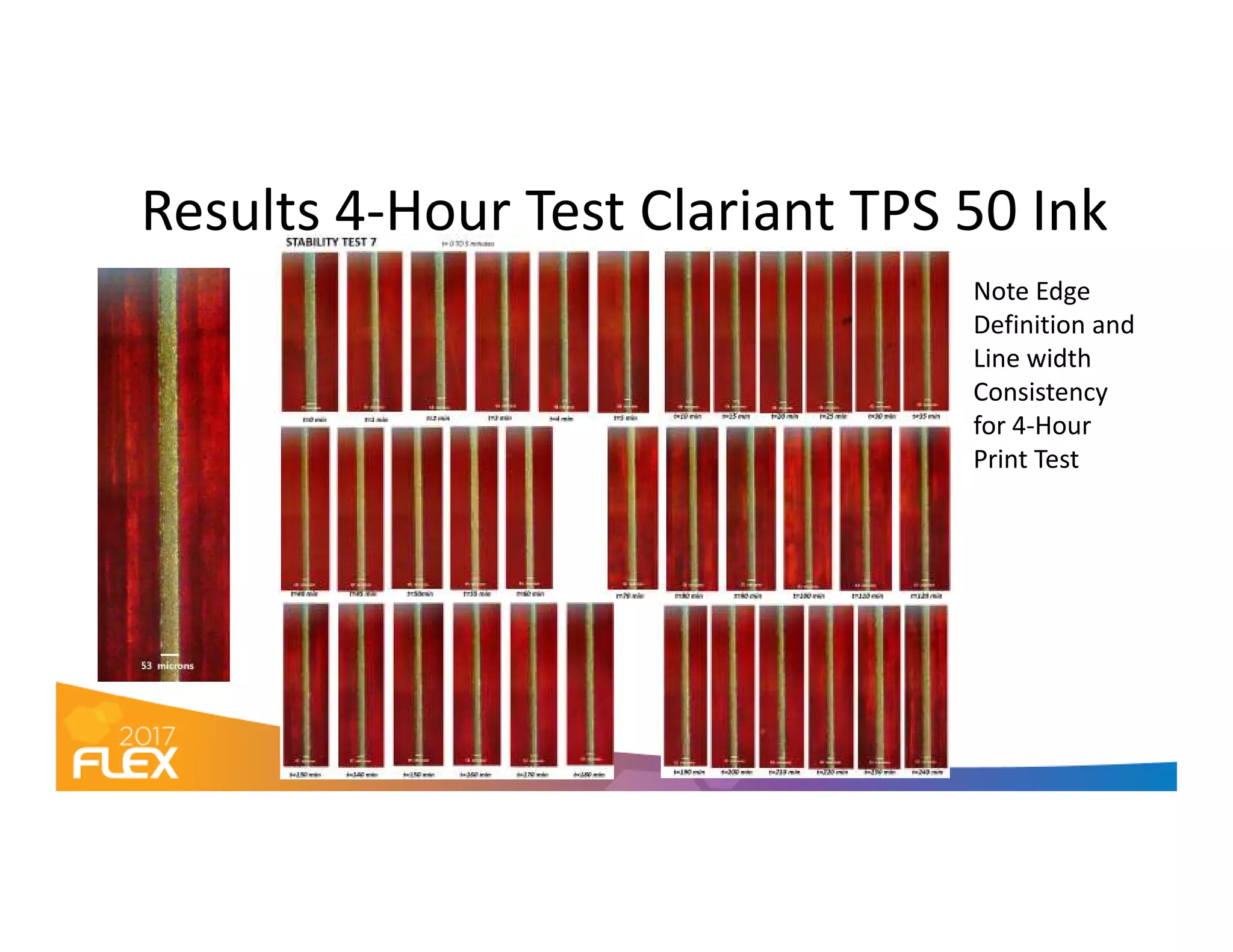

This document summarizes research on developing an aerosol-based printing system for production-level printed electronics. Key points:

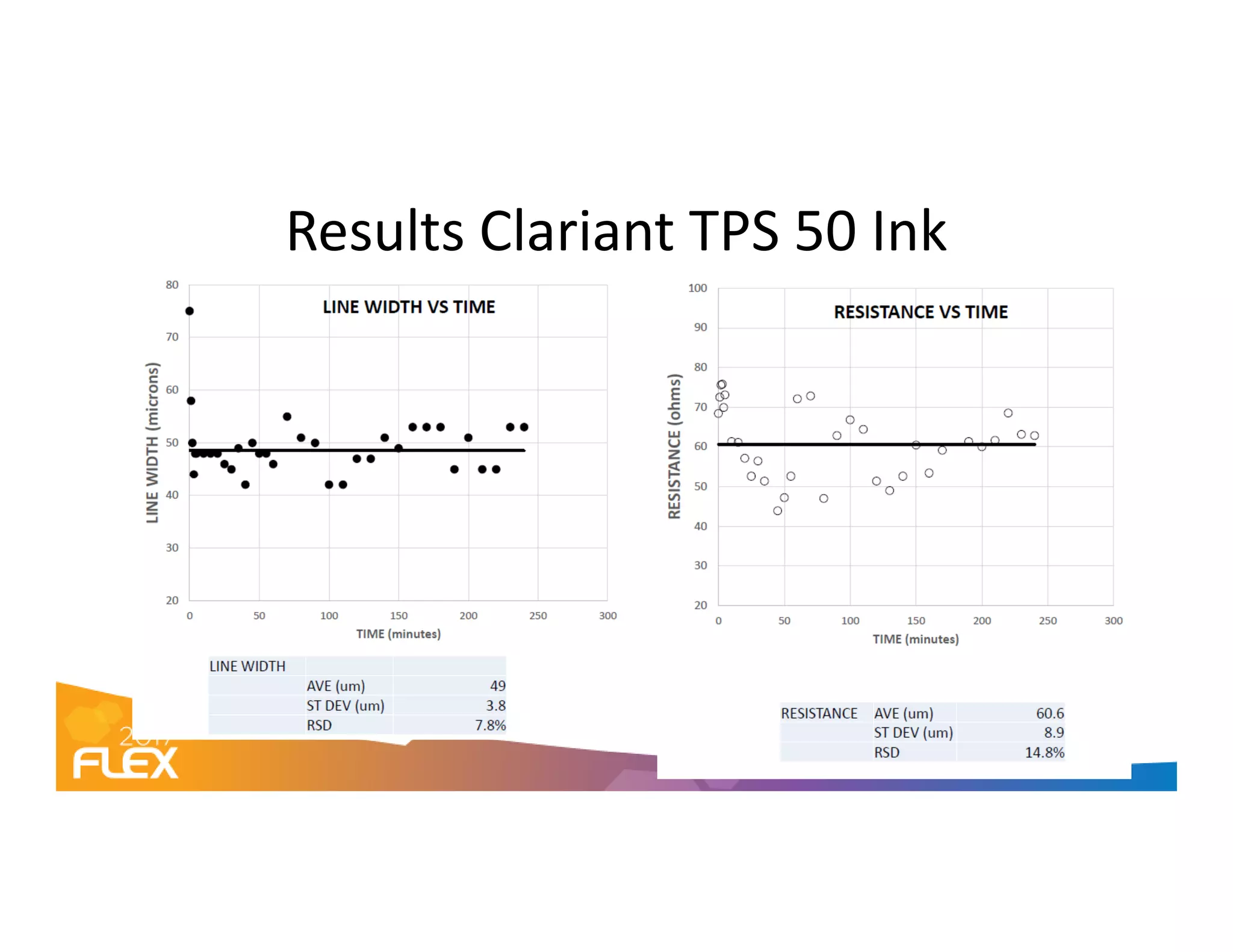

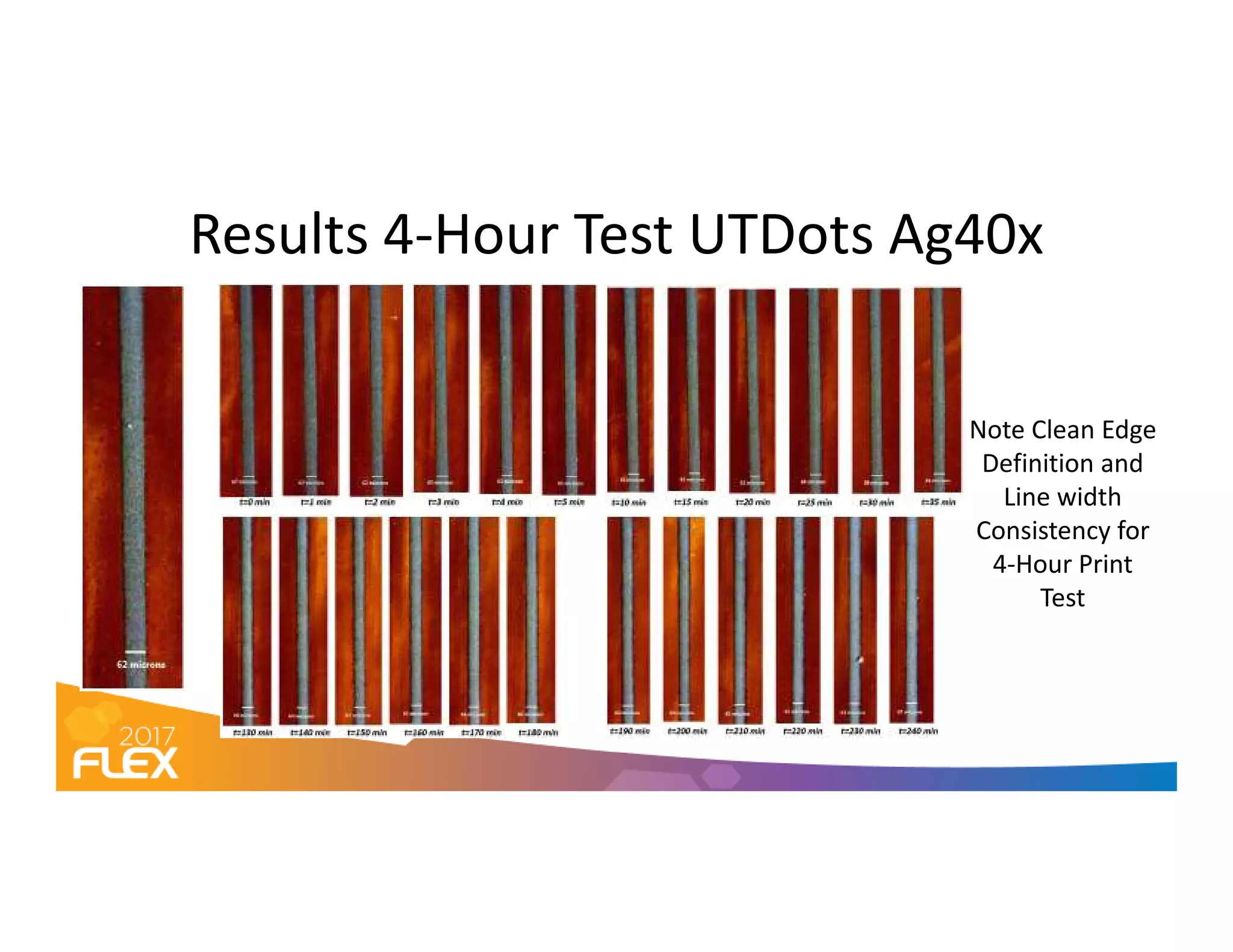

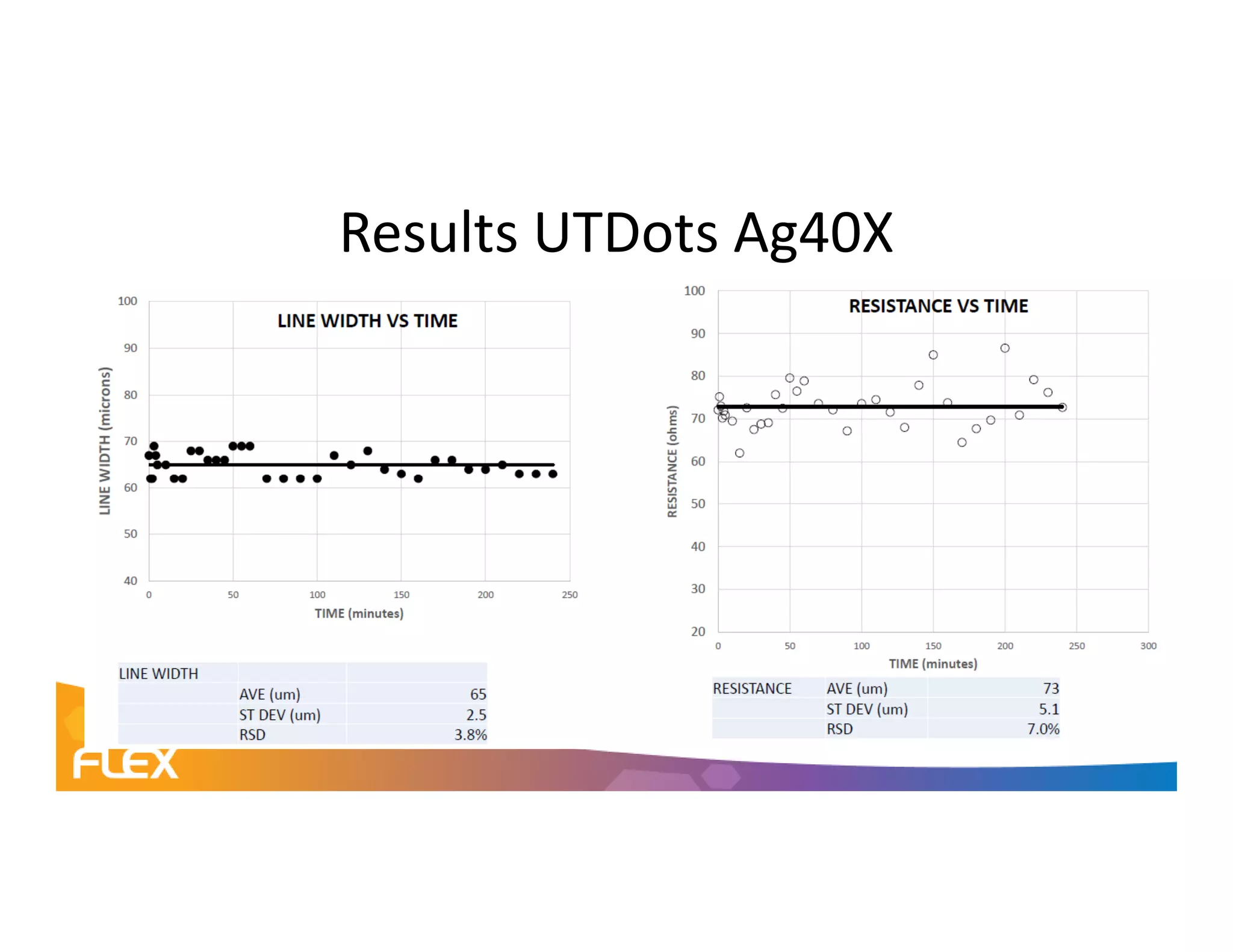

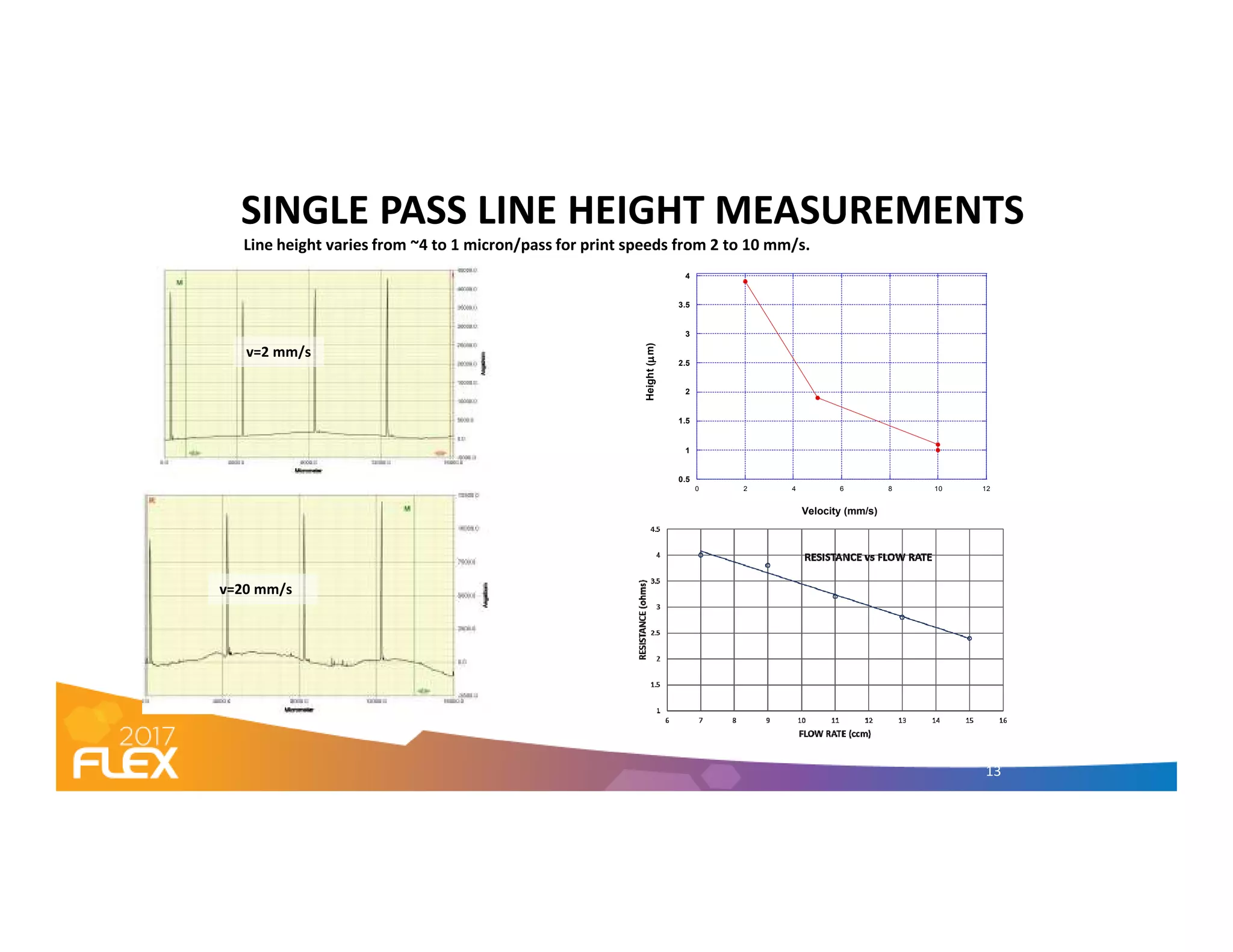

- Researchers created a next-generation aerosol print head and conducted 4-hour test prints with conductive and dielectric inks, achieving consistent line widths and resistivities.

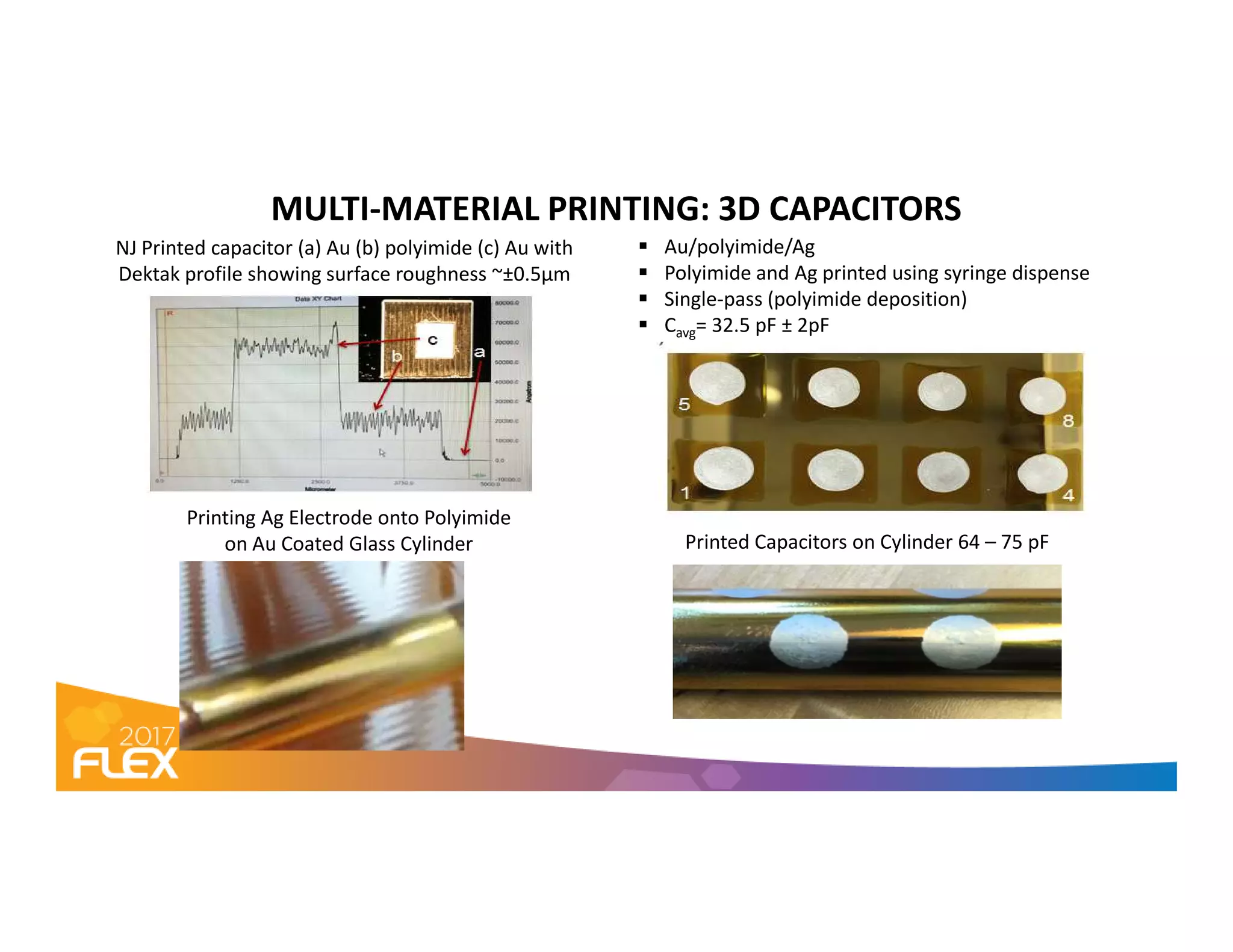

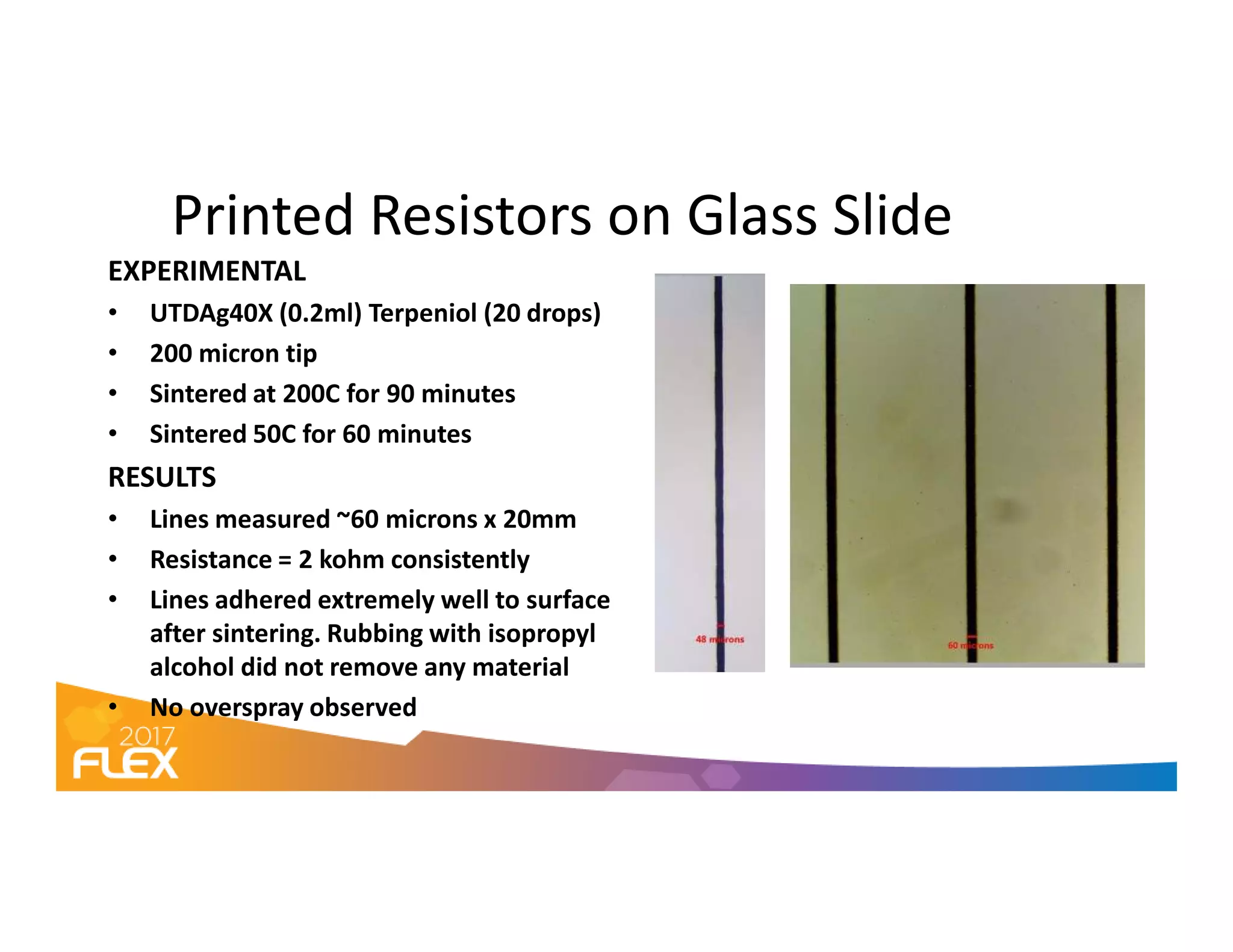

- Single-pass printing was used to print capacitors with widths of 32.5pF and resistors with resistances of 2kOhm.

- Future work involves testing the system for longer print times, larger area printing, multi-nozzle and multi-material printing, and applying the technology with internal and external customers.