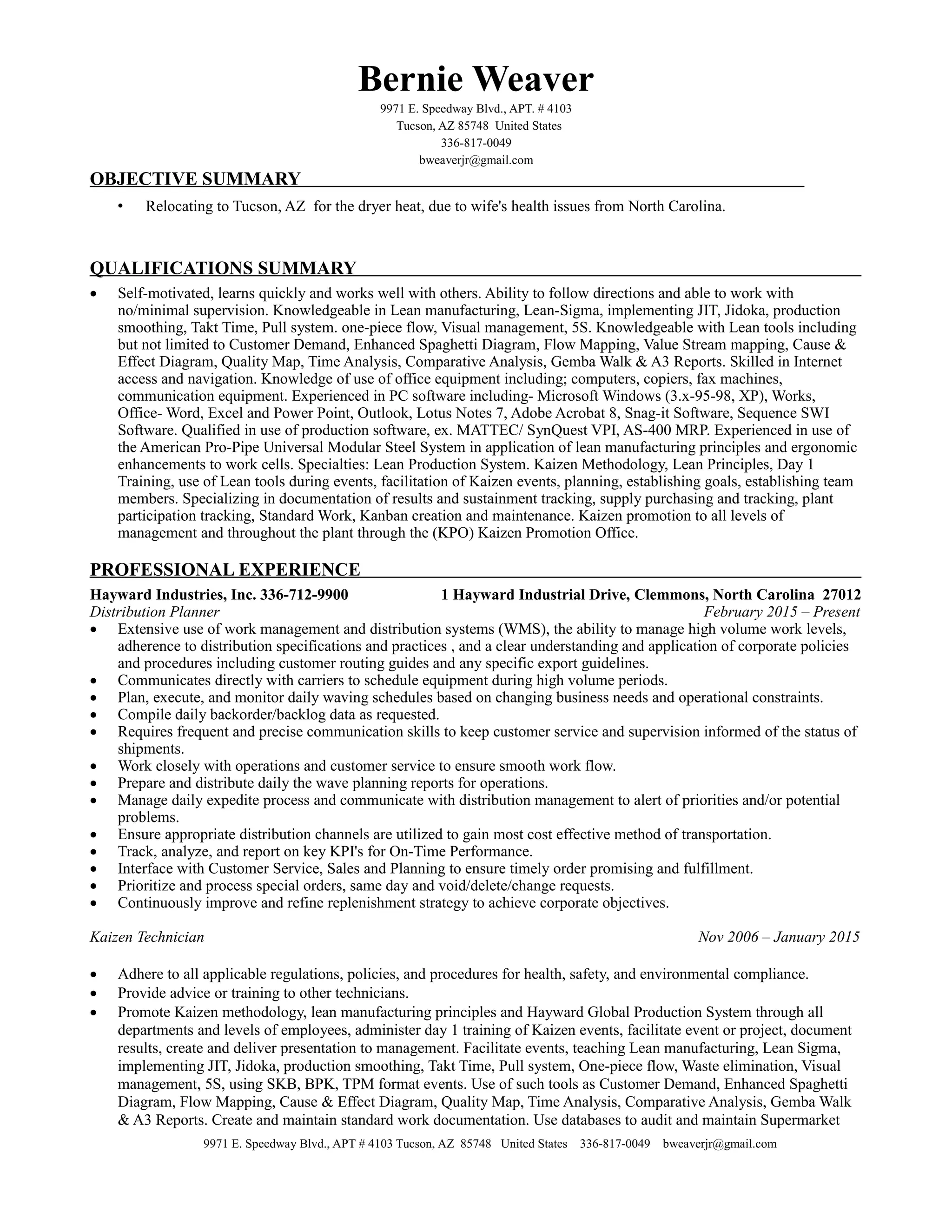

Bernie Weaver is relocating from North Carolina to Tucson, Arizona for his wife's health issues. He has over 15 years of experience implementing lean manufacturing principles through kaizen events and as a kaizen technician. Currently he works as a distribution planner planning shipping schedules and ensuring on-time delivery. He is pursuing an AAS in Business Administration from Forsyth Technical Community College.