The document provides information on PIX hoses, including:

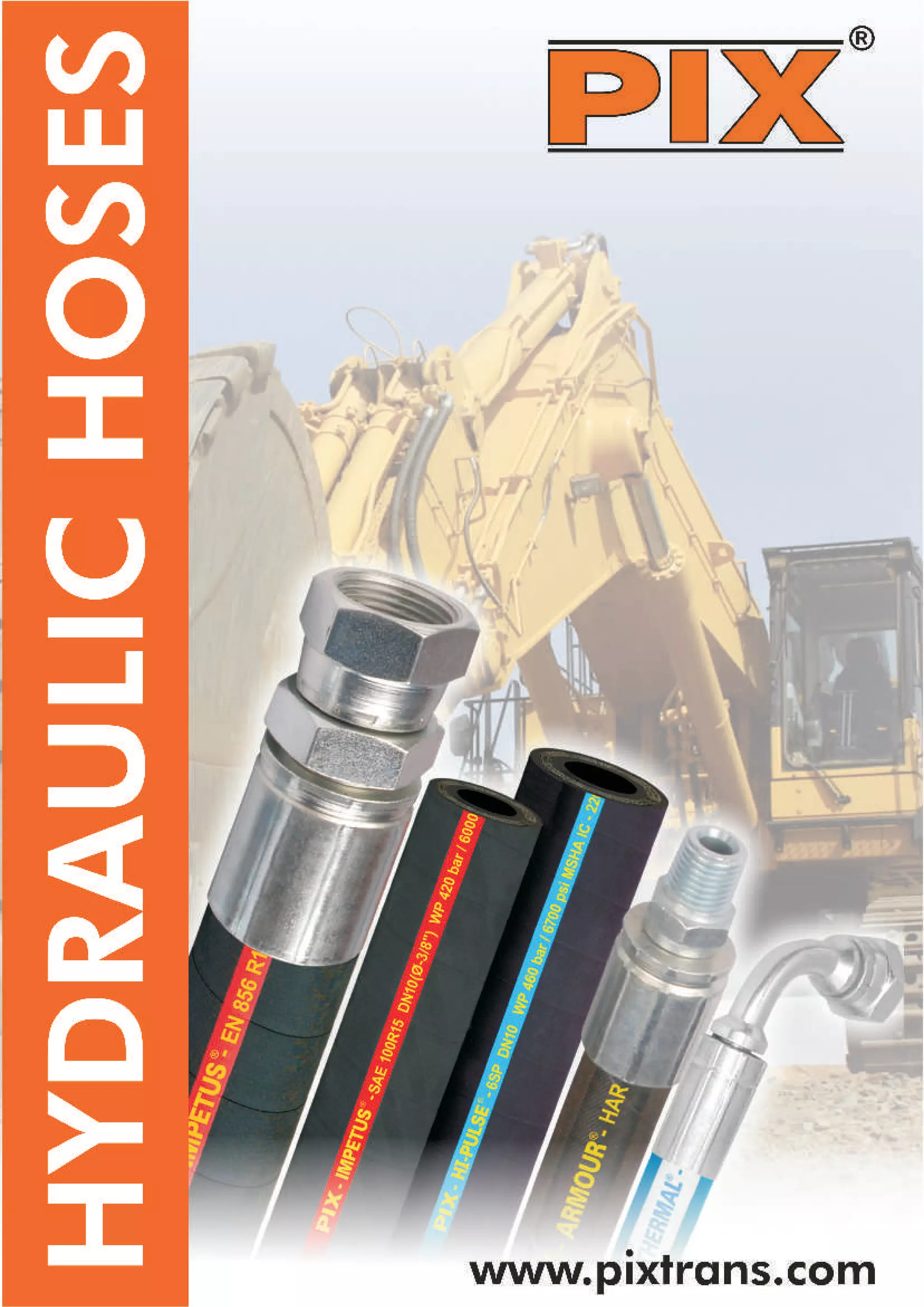

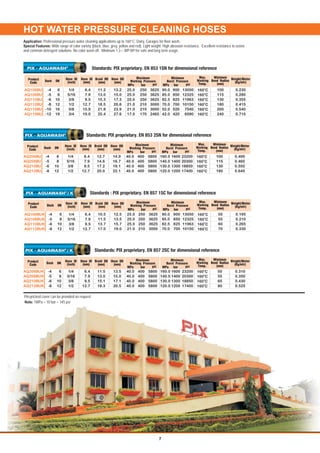

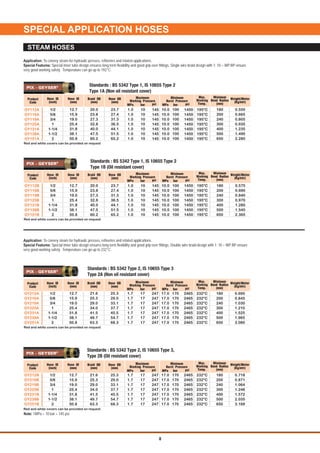

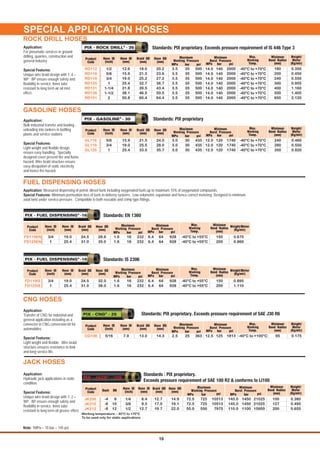

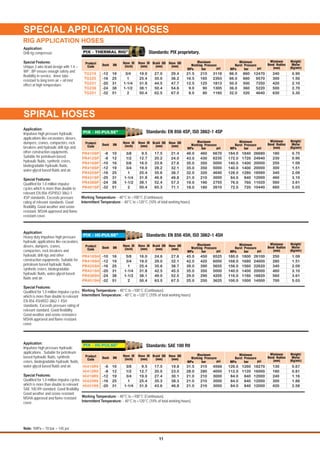

- PIX manufactures a wide range of hydraulic hoses that are certified to standards like MSHA, DNV, and DGMS.

- The hoses come in various sizes and are suited for applications in industries like mining, construction, agriculture, and manufacturing.

- PIX has testing facilities to ensure product quality and performance.