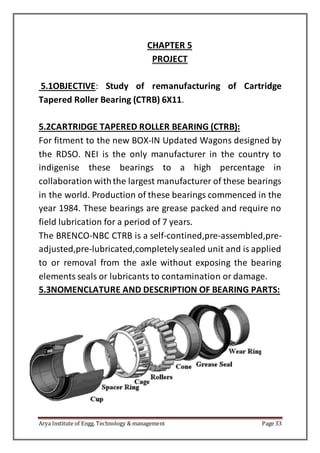

The document discusses the manufacturing process of ball bearings and tapered roller bearings. It begins by describing the raw materials used, which is typically steel alloyed with carbon and chromium. It then outlines the major steps in ball bearing manufacturing, which are: cutting the outer and inner races to rough size from steel tubing, heat treating the races to harden them, finishing the races to precise sizes after heat treating, producing steel balls from wire in a cold heading process, assembling the balls and races along with a steel or plastic cage. The document also provides details on the manufacturing processes for individual parts of tapered roller bearings.