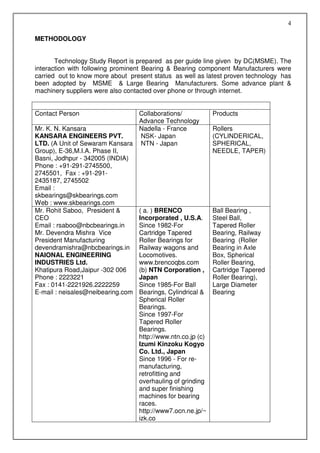

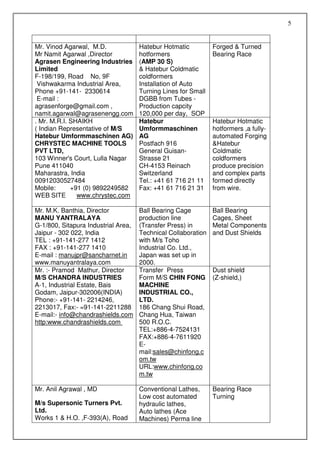

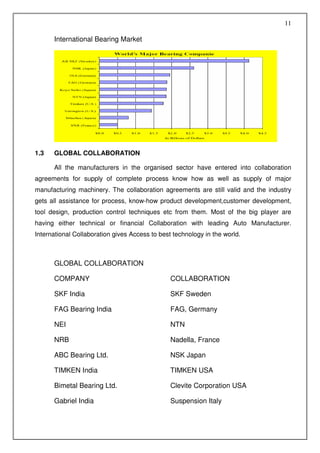

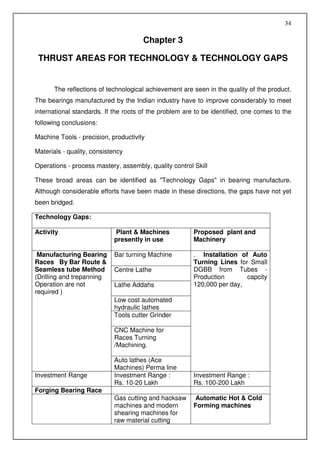

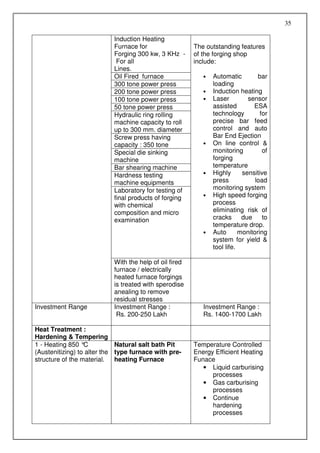

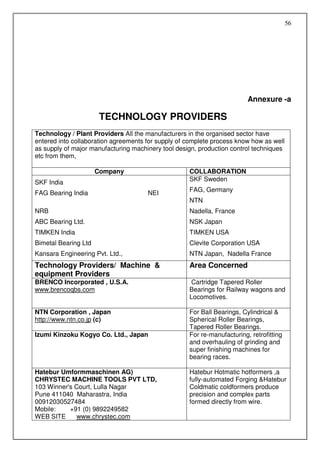

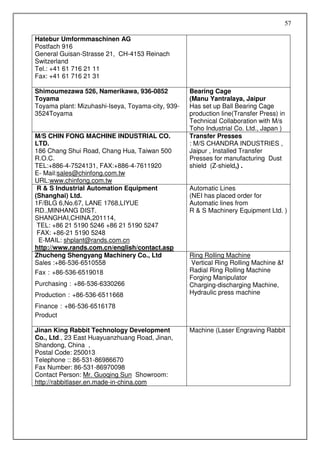

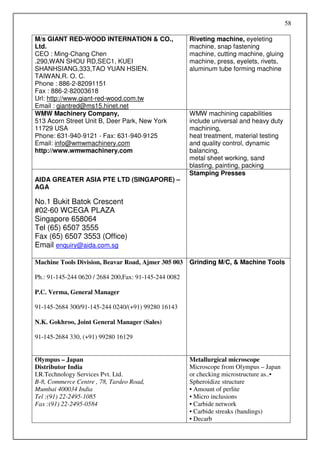

The document provides an overview of the bearing industry in India. It discusses the present status of technology used, which is primarily conventional in the unorganized sector but more advanced in the organized sector. It also describes India's bearing industry in terms of its segments, key manufacturers both domestic and global, and international collaborations that Indian manufacturers have entered into for technology transfers. The top bearing producing states in India are Rajasthan, Gujarat, Maharashtra, and Tamil Nadu.