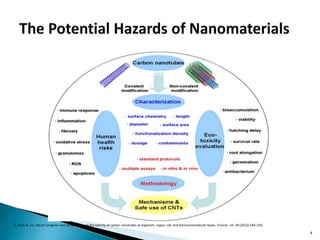

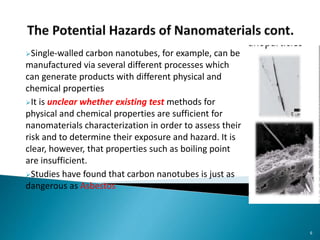

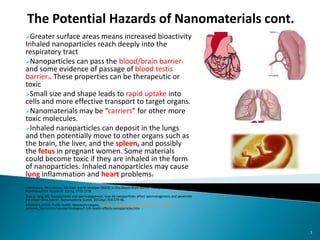

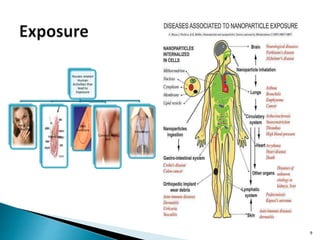

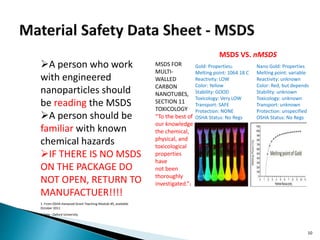

The document summarizes key topics related to nanosafety in a nanomaterials and nanotechnology course taught by Dr. XA Sun. It discusses potential hazards of nanomaterials, important considerations for nanosafety including proper personal protective equipment, engineering controls, and safe handling practices. It also notes challenges in characterizing nanomaterials and a lack of standards and regulations. The document emphasizes the need for more research on nanosafety and collaboration between researchers and environmental health and safety experts to develop effective safety protocols and practices.