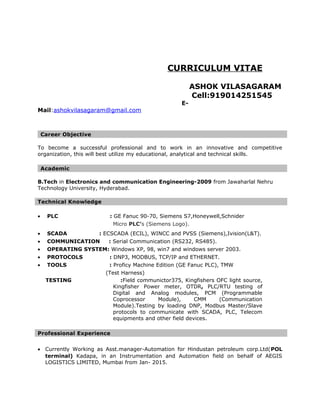

This curriculum vitae is for Ashok Vilasagaram, who has over 10 years of experience in instrumentation and automation. He has worked on projects for Hindustan Petroleum Corporation Limited. He is currently working as an Assistant Manager of Automation for HPCL in Kadapa, India. His experience includes maintenance of field instrumentation, SCADA systems, PLCs, CCTV, fire alarms and more. He has expertise in protocols like DNP3, Modbus, TCP/IP and operating systems like Windows and Linux.