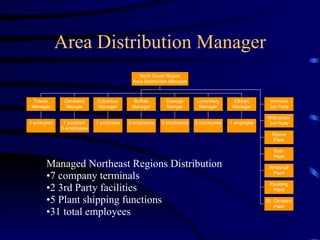

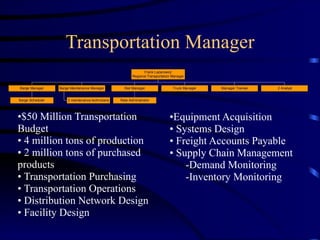

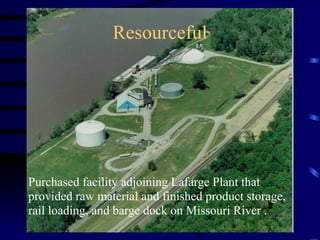

Frank Lazarowicz has extensive experience leading logistics, distribution, and supply chain management operations for Georgia-Pacific. He developed their logistics vision and oversaw a $100 million capital project to retool several plants. As Regional Transportation Manager, he managed a $50 million transportation budget and distribution network for 4 million tons of production and 2 million tons of purchased products. He established various facilities and operations to improve efficiency and lower costs, including a private stevedoring operation, truck fleet, and trans-load terminal.