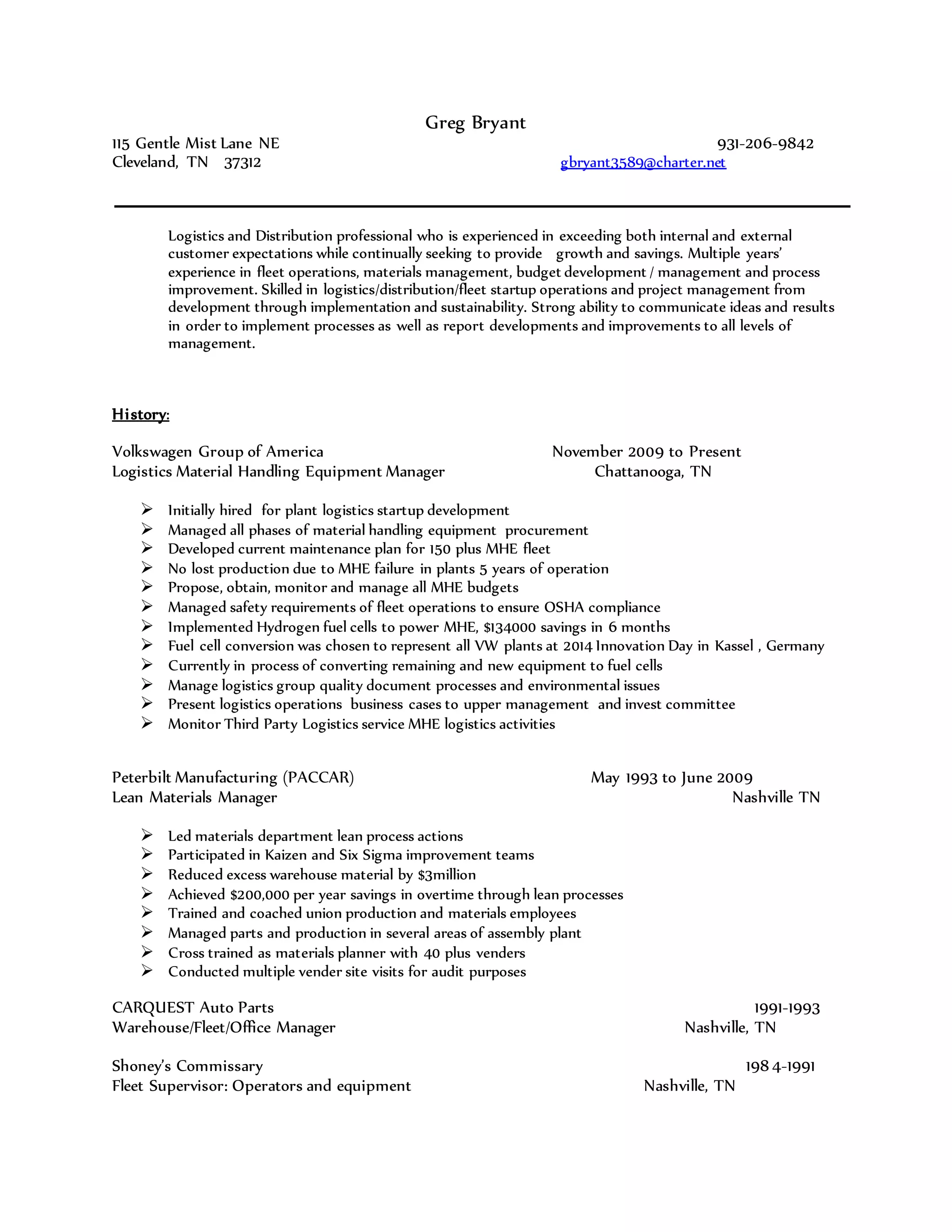

Greg Bryant has over 25 years of experience in logistics and distribution management. He is currently the Logistics Material Handling Equipment Manager at Volkswagen Group of America, where he has implemented initiatives that have saved over $134,000 in six months by converting equipment to hydrogen fuel cells. Previously, he held leadership roles at Peterbilt Manufacturing and CARQUEST Auto Parts, where he led lean process improvements and achieved significant cost savings. He has a bachelor's degree in business administration from Kennesaw State University.