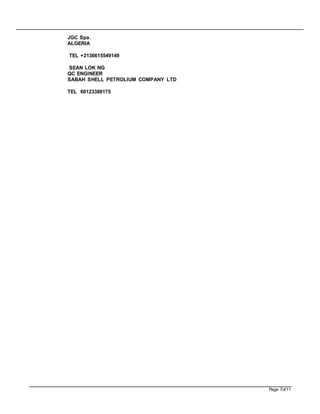

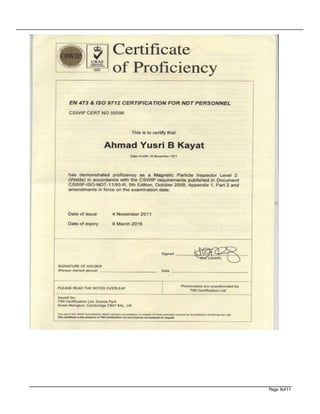

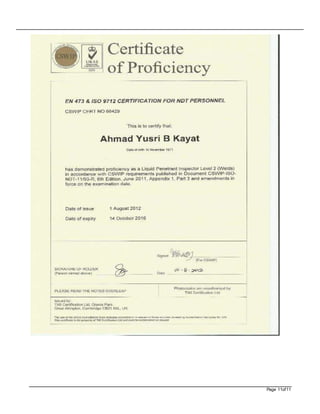

This curriculum vitae provides a summary of Ahmad Yusri Kayat's professional experience and qualifications. Over 17 years, he has worked in oil and gas engineering inspection for various projects involving fabrication yards, power plants, and oil and gas industries. He has extensive experience performing quality control inspections including material verification, welding inspections, non-destructive testing like magnetic particle testing, radiography, and coating inspections. He is qualified in CSWIP welding inspection and NDT methods. His most recent role is as a tank and piping inspector for JGC Malaysia on the PETRONAS LNG9 Complex Tank7 Piping New Jetty Project.