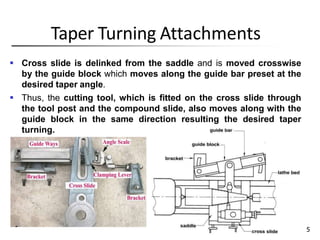

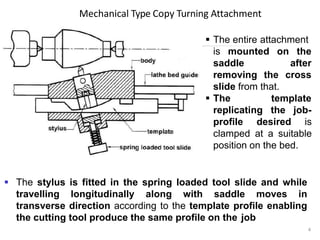

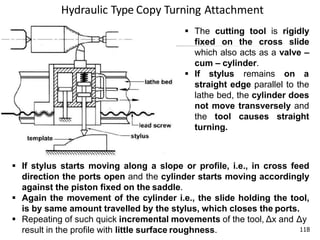

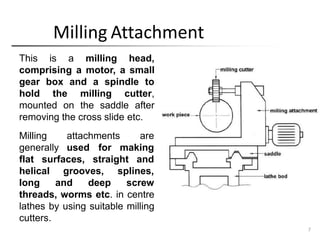

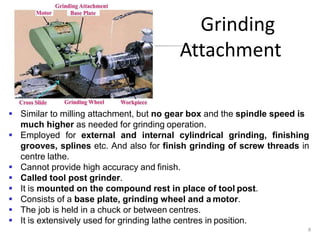

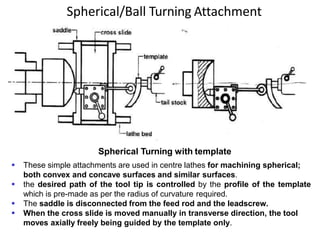

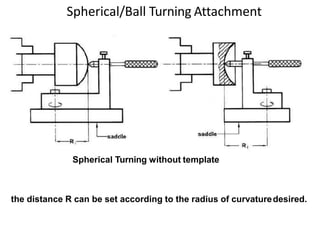

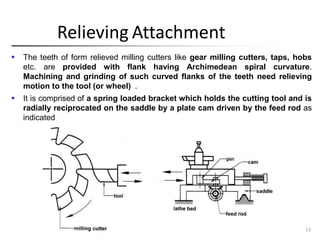

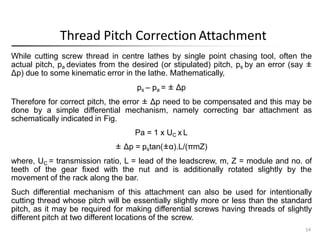

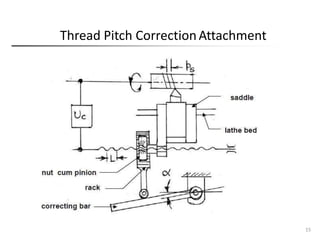

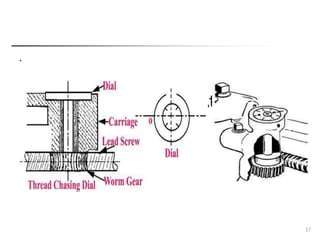

The document discusses various attachments that can be used on lathe machines to expand their capabilities. It describes taper turning, copy turning, milling, grinding, spherical turning, relieving, thread pitch correction, and thread chasing attachments. These attachments allow lathes to perform tasks like tapering, copying profiles, milling, grinding, spherical cuts, relieving complex tooth profiles, correcting thread pitches, and ensuring accurate multi-pass thread cutting.