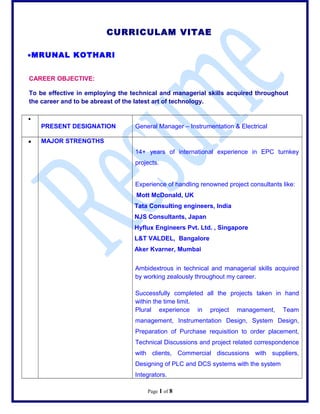

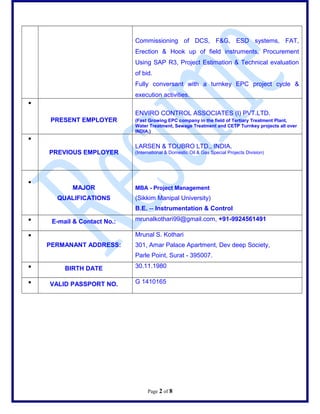

Mrunal Kothari's CV summarizes his career objective and experience in instrumentation and project management over 14+ years. He currently serves as General Manager of Instrumentation & Electrical at Enviro Control Associates, leading automation and electrical work on large wastewater treatment projects across India. Previously, he worked at Larsen & Toubro on oil and gas projects internationally in Qatar and domestically in India. He holds an MBA in Project Management and a B.E. in Instrumentation & Control.